5.52.270.00.01.04

11

11.4

Clamping jaws

If the clamping jaws are worn, they must be replaced by original clamping jaws.

12

Inspection

12.1

Periodic checks

Independently from the regulations of the individual countries, lifting devices must be checked at least yearly

by a qualified person or licensed qualified person regarding its functional safety.

12.2

Wire rope

Adequate performance of the servicing and monitoring work acc. to the validated, national regulations

“Basics for cable drives – monitoring during use”.

A visual check must be effected before every new work shift.

Wear

Deformation

Fissures

Corrosion

Report any damage immediately to the responsible person and exchange damaged or worn wire ropes and

load tackles.

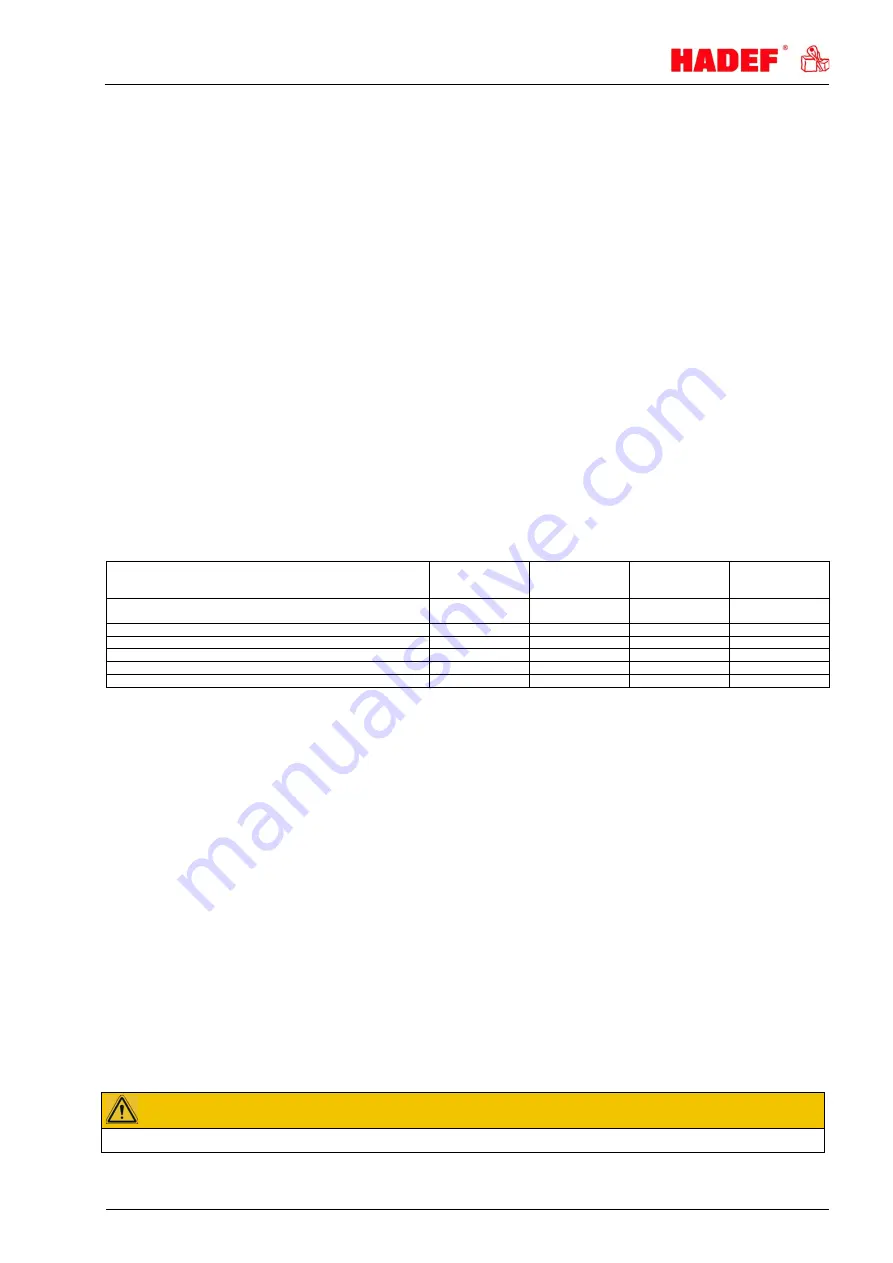

12.3

Inspection intervals

at

putting indo operation

daily checks

inspection, mainte-

nance every

3 months

inspection, mainte-

nance every

12 months

inspection of the equipment by an expert

(periodic inspection)

X

check screw connections

X

X

check brake function

X

X

check the safety pin for deformation

X

check clamping jaws for wear

X

lubrication - wire rope *)

X

*) shorten maintenance intervals in case of increased dirt or heavy charge of the equipment

13

Service

13.1

Wire rope

Wire ropes have to be exchanged by new, original wire ropes if they show corrosion, fracture or if they are

worn.

Checks:

Fastening screws must be checked before commissioning and at least every 3 months, - tighten them if

necessary.

Kind and number of broken threads.

Position of the broken threads

Timing sequence of occurrence of breaks.

Reduction of the wire rope diameter.

Corrosion

Abrasion

Deformation

Heat influence

Operation time

Wire rope fastening

CAUTION!

The wire rope must be replaced immediately should even one strand be broken.