5.52.653.01.01.04

15

9

Safety check

Before putting into service initially or when putting back into service, it must be checked whether:

All fastening screws (if existent), socket pins, flap socket and safety devices are tightened and secured.

10

Functional test

10.1

Checks before the initial start-up

Trolley drive

The open-lying teeth of the trolley drive must be lubricated.

Hand gear for hand geared trolley

Ensure correct fit of the hand chain; it must not be twisted and must hang freely.

10.2

Functional test

Trolleys

Carefully move the trolley to the end positions and check the positions of the end stops.

11

Maintenance

11.1

General

All monitoring, servicing and maintenance operations are to ensure correct functioning of the equipment;

they must be effected with utmost care.

Only

“qualified persons” may do this work.

Servicing and maintenance work must only be done when the hoist is not loaded.

Records must be kept of all test results and measures taken.

11.2

Monitoring

The monitoring and servicing intervals stated are valid for operation under normal conditions and single-shift

operation. In case of severe operating conditions (e.g. frequent operation with full load) or special

environmental conditions (e.g., heat, dust, etc.), the intervals must be shortened correspondingly

12

Inspection

12.1

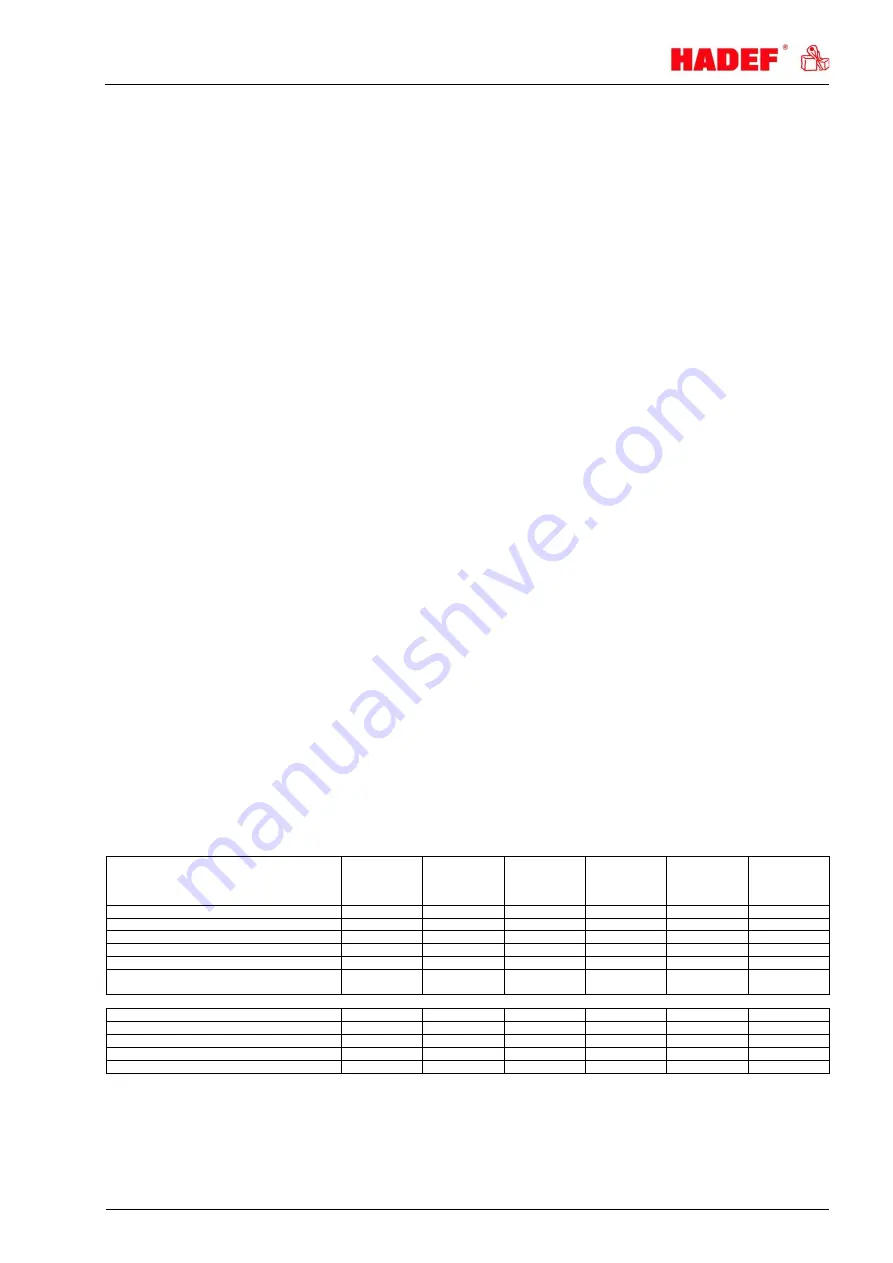

Periodic checks

Independently from the regulations of the individual countries, lifting devices must be checked at least yearly

by a qualified person or licensed qualified person regarding its functional safety.

at

commissioning

daily

checks

1st maintenance

after

3 months

Inspection

Maintenance

every

3 months

Inspection

Maintenance

every

12 months

check screw connections

X

X

check the bearings

X

check the trolley wheels

X

check lubrication of the driving pinion

X

X

buffers - check correct position and wear

X

X

Have the equipment checked by an expert

(periodic inspection)

X

*as far as applicable

remove dust (do not use compressed air to do so)

X

Check device for corrosion

X

X

check lubrication/ grease - bearings

X

X

check lubrication/ grease - driving pinion

X

X

name plates - check for existence and legibility

X

13

Service

Maintenance must be effected by lubricating the driving pinions (for hand geared trolleys) and by checking

the rubber end stops.