8

5.52.162.00.01.05

In case of ex proof hoists, the housing is only made of steel plates.

Load chain

According to EN 818-7-T high quality chain. All components match precisely to each other. Therefore please

only use original chains.

Load hook

Forged steel. Rotating, this facilitates attaching the load and avoids twisting of the chain. With safety catch.

5

Technical data

HH

Capacity

kg

500

1000

1500

2000

3000

5000

7500

10.000

Number of chain falls

1

1

1

1

2

2

3

4

Load chain

mm

5 x 15

6,3 x 19,1

7,1 x 21

8 x 24

7,1 x 21

9 x 27

9 x 27

9 x 27

Load bar size at beam flange width

from - to

1N

mm

50-146

50-179

66-185

66-185

74-196

74-192

119-215

119-215

Load bar size at beam flange width

from - to

2

Nmm

147-302

180-310

186-310

186-310

197-310

193-310

216-310

216-310

Lifting path when reeling off

30 m of hand chain

mm

1112

690

519

423

260

151

101

67

Hand chain pull for lifting

daN

23

28

34

35

35

33

34

35

Travel path when reeling off

30 m of hand chain

m

7,8

10

9,8

9,8

6,3

6,3

6,3

6,4

Hand chain pull for travel

N

65

100

110

150

110

170

190

210

weight at 3 m track height

approx. kg

22

31

52

56

92

121

230

250

weight per add. m lift

kg

2,5

2,8

3,1

3,3

4,2

5,4

7,2

8,9

HR

Capacity

kg

500

1000

1500

2000

3000

5000

Number of chain falls

1

1

1

1

2

2

Load chain

mm

5 x 15

6,3 x 19,1

7,1 x 21

8 x 24

7,1 x 21

9 x 27

Load bar size at beam flange width

from - to

1N

mm

50-146

50-179

66-185

66-185

74-196

74-192

Load bar size at beam flange width

from - to

2

Nmm

147-302

180-310

186-310

186-310

197-310

193-310

Hand chain pull for lifting

daN

23

28

34

35

35

33

weight at 3 m track height

approx. kg

21

27

47

51

86

114

weight per add. m lift

kg

1,5

1,8

2,1

2,3

3,2

4,4

6

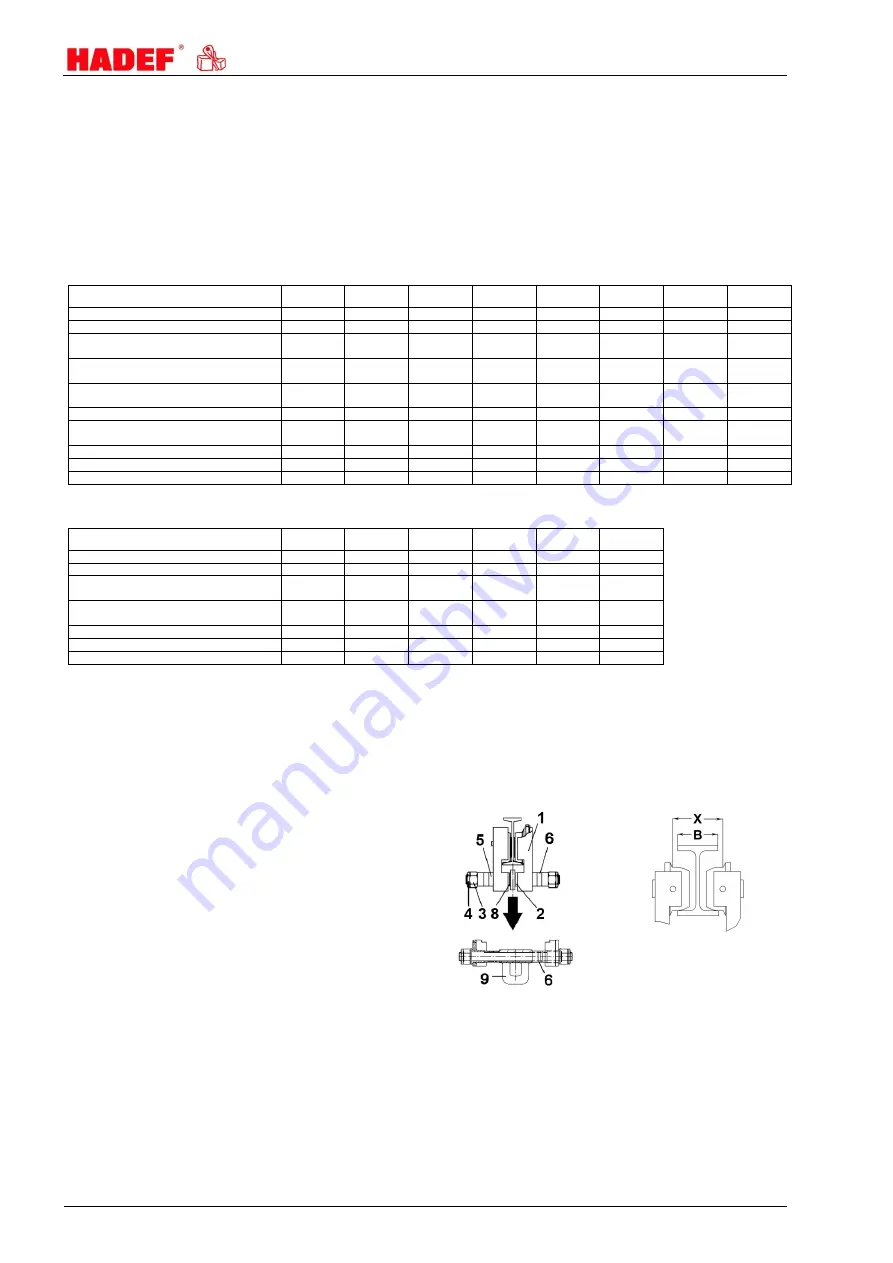

Installation

6.1

Adjusting the gauge

The trolley can be adjusted to various beam flange widths. Adjustment to the relevant beam flange width “B”

depends on the type and size and is to be made as follows:

There are distance tubes (5) and/or washers

(6) situated on the load bars (2) of the trolley.

Dimension "X" is set by placing washers (6)

from the outer to the inner side ("X" increases)

or from the inner to the outer side ("X"

decreases).

Washers (6) and rubber discs (depended on

type) leave a distance for the load hook. It is

important that the load hangs in the middle

under the beam so that the two side plates are

equally loaded.

The suspension eye (9) (if existent) for bigger

load bolts must still be swivelling after it has

been secured.

Tighten the hexagon nut (3) and safety nuts (4)

again.

Check correct flange width "B" and dimension

"X". Adjustment must be repeated if necessary.

1 side plates

2 load bars

3 hexagon nut

4 safety nuts

5 distance tubes

6 washers

7 ---

8 rubber disc (depended on type)

9 suspension eye