5.52.162.00.01.05

13

on

commissioning

daily

checks

1st maintenance

after

3 months

Inspection

Maintenance

every

3 months

Inspection Mainte-

nance

every

12 months

Check screw connections

X

X

Check lifting, lowering functions.

X

X

Check brake function

X

X

Check free-wheeling of chain

(only applicable for ratchet lever hoists with free-wheeling

mechanism)

X

X

Brake - check the brake disc thickness

X

Check sprocket wheels, ratchet wheels, pawls, bolts

X

Clean and lubricate the load chain

X

X

X

Check the load chain for elongation and wear

X

Check the load hook for cracks and deformation

X

Load hook - check the safety latch

X

X

Check and lubricate the bearing of the chain pulleys

X

X

Check the chain pulleys

X

X

Check the rubber end stops

X

X

X

Check the trolley wheels for wear

X

Check lubrication of the trolley driving pinion

X

X

X

Have the equipment checked by a qualified person

(periodic inspection)

X

WARNING!

If one or several of the dimensions fall below or exceed the dimensions in the table, or if cracks or

corrosion are found, the parts must be replaced with original spare parts.

12.2

Checking the load chain

CAUTION!

The load chain must be tested over its entire length!

The measure of the load chain must be carried out especially in the areas which are subject to the highest

wear. Through the lifting movement, these are the contact points of the chain with sprocket wheel and

deflection pulleys.

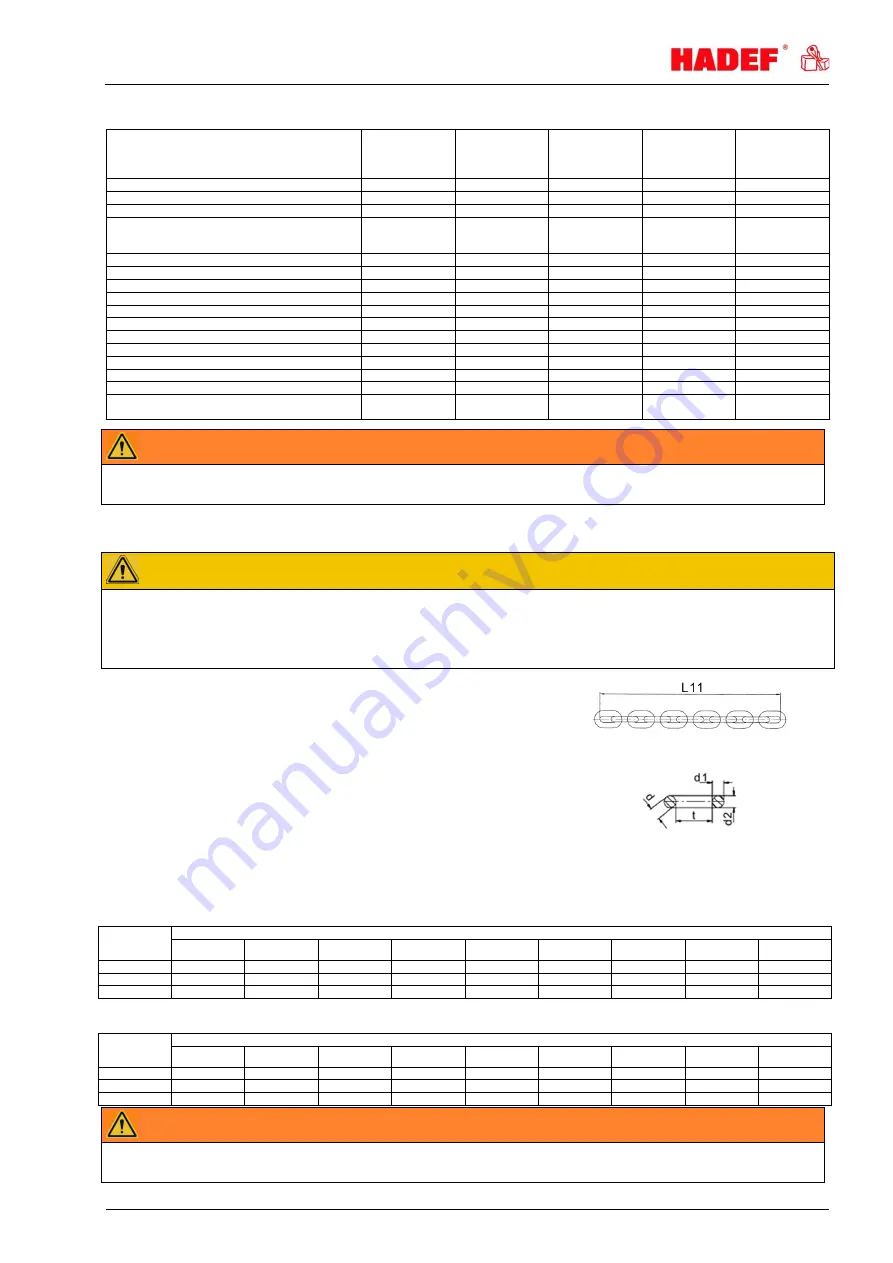

acc. DIN 685-part 5

L11 = pitch increase over 11 chain links

L1 = pitch increase over 1 chain link

Illustration 7

dm= detected link diameter (d1+d2)/2

Illustration 8

Chain dimensions

Table 1

Dimensions

mm

Chain size

3x9

4x12

4,2x12,2

5x15

5,6x15,8

5,6x17

6x18

6,3x19,1

7,1x20,1

L11

105,6

136,6

138,2

170,6

179,1

194,2

203,9

216,4

227,9

L1

9,9

12,7

12,8

15,7

16,6

18

18,9

20

21,2

dm

2,7

3,6

3,8

21,2

5,0

5,0

5,4

5,7

6,4

Table 2

Dimensions

mm

Chain size

7,1x21

7,9x23

8x24

9x24,8

9x27

10x28,1

10x30

13x36

16x45

L11

238,5

260,6

272,1

281,2

300,8

318,6

340,7

408,3

505,6

L1

22,3

24,1

25,3

26,1

28,1

29,6

31,8

37,9

47,4

dm

6,4

7,1

7,2

8,1

8,2

9,0

9,0

11,9

14,4

WARNING!

When the dimensions listed in the table are reached due to wear or deformation, the chain must be

replaced!