12

5.52.208.01.01.02

Winches with separating partition

Capacity

FEM

group

wir-

erope

Ø

2x

nec.

minimum

breaking

load

2x

useable

wire rope length

2x

number of

rope layers

2x

wire rope

path per

crank turn

crank

effort

weight

without rope

approx.

1st layer

top layer

1st layer

top layer

kg

kg

1 Cm

mm

kN

m

m

mm

daN

kg

2 x 125

2 x 45

1 Cm

3

4,5

2

80

16

17

6

13,5

2 x 250

2 x 110

1 Cm

4

9

3

76

13

20

10

16,5

2 x 500

2 x 265

1 Cm

6

17

3

55

9

13

13

27,5

2 x 750

2 x 400

1 Cm

8

34

2

32

7

9

14

28,5

2 x 1000

2 x 525

1 Cm

8

34

3

60

9

12 (6)

22 (12)

62

2 x 1500

2 x 785

1 Cm

10

51

4

70

9

11 (6)

27 (14)

80

2 x 2500

2 x 1540

1 Cm

12

79

4

50

7

12 (4)

58 (17)

119

() with crank changed in position

6

Installation

Please observe the following points in order to avoid any damage to equipment or injury of person:

Wear safety gloves.

Install the winch on a stable ground.

Make sure attachment surface is flat and that installation is made stress-free, - use shim parts if

necessary.

The winch must be set up and attached in such a way that it cannot change position neither by the load

nor by other influences.

The winch must always be aligned with the horizontally adjusted drum, regardless of the installation

position

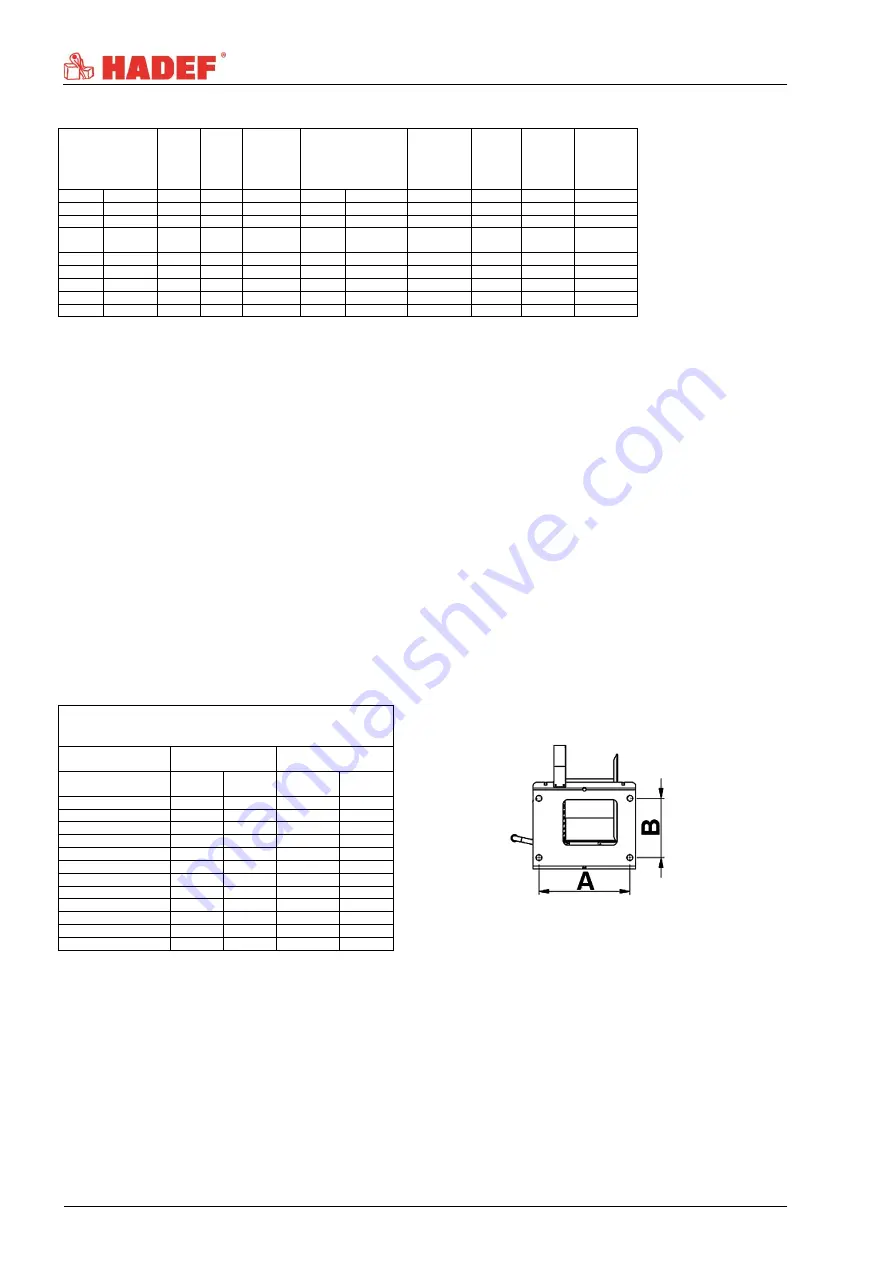

6.1

Installation of the winch

The winches can be installed in any position desired, make sure, however, that the prescribed rope exit is

correct.

Make sure the attachment surface is flat/plain and that installation is made stress-free to ensure safe

functioning.

Use the screws mentioned in the table for installation. Tighten all screws evenly.

Distance of holes

Capacity

1st layer

holes of the

installation area

fastening screws

4x

A

B

strength

8.8

Tightening

moment

kg

mm

mm

Nm

250 (2x125)

192

100

M12

87

500 (2x250)

223

115

M12

87

1000 (2x500)

254

141

M12

87

1500 (2x750)

254

178

M12

87

2000 (2x1000)

360

196

M20

431

3000 (2x1500)

386

251

M20

431

5000 (2x2500)

386

316

M20

431

7500

455

350

M20

431

*MV 1500

165

210

M16

214

*MV 3000

446

251

M20

431

*MV 5000

456

316

M20

431

*MV = Marine-Version

6.2

Selection of wire ropes

Wire ropes acc. to EN 12385-4 - Lifting ropes

Stainless wire ropes and special wire ropes are available on request.

Diameter and nec. minimum breaking load must be acc. to the data mentioned in the table in chapter

"Technical Data" resp. acc. to the details mentioned on the type plate.

Recommendation of wire ropes

Steel-reinforced wire ropes

For larger pulling rope forces, fibre-core wire ropes can also be used.

For unguided loads, - non-twisting or at least twist-resistant wire ropes.

For several rope layers winded through the drum, - steel-reinforced wire ropes.