12

5.52.181.01.01.07

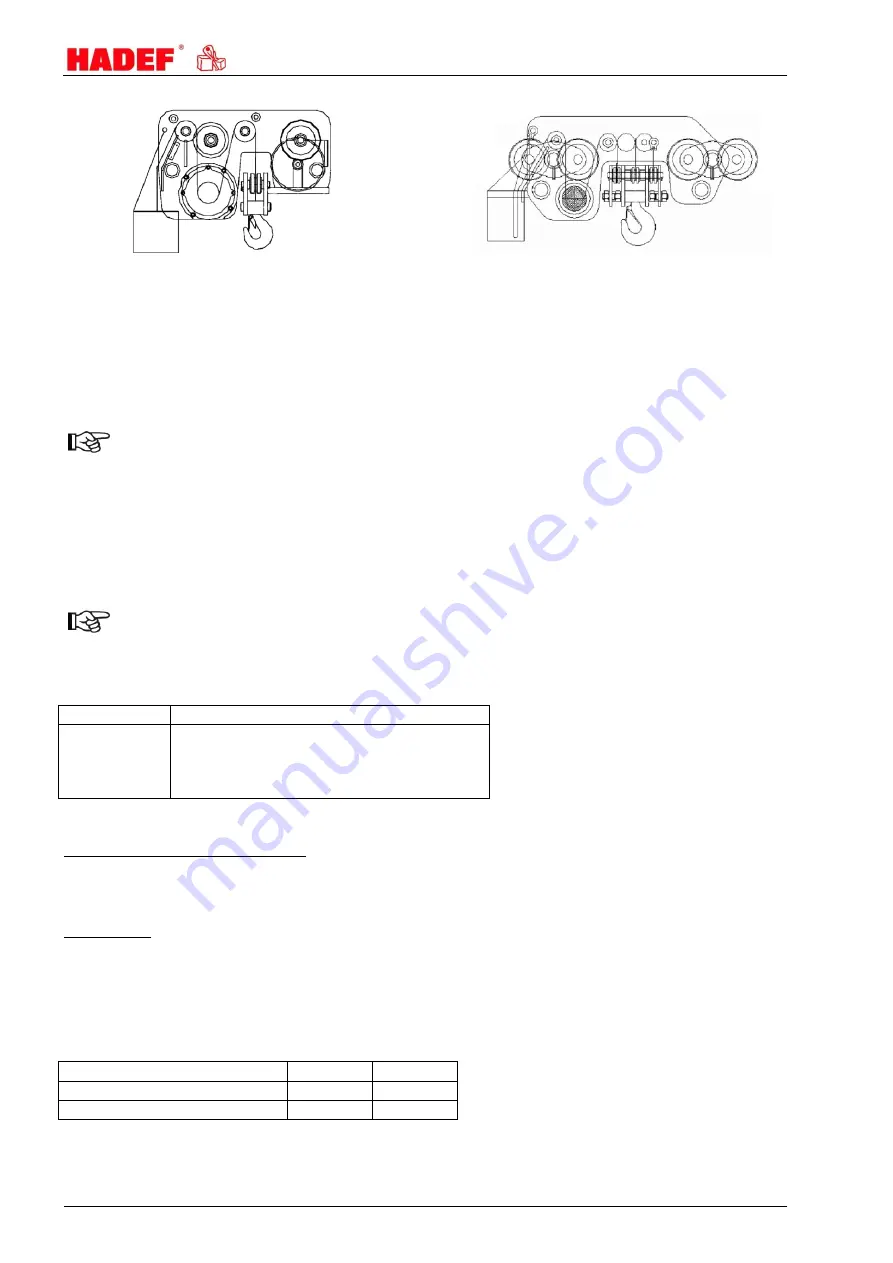

Type 29/06 APH - Table 2 / 8-20T

Type 29/06 APP - Table 2 / 26-60T

4.3

Functions

The lifting gear and motor-driven trolleys are moved by pressing the buttons on the control switch. The

spring-operated brake which is integrated in the lifting motor prevents the load from being lowered

automatically after releasing the control keys.

Hand geared trolleys are moved to the left or right by pulling one of the two stands of the endless hand

chain.

NOTICE!

The best protection against functional failures in case of extreme environmental impact is the regular use of

the equipment.

If the hoist is not used very often, we recommend to carry out a test run at least once a week and to switch

on the motor several times during this test run.

In our experience, this will prevent the brake from sticking.

4.4

Important components

NOTICE!

All hoists are fitted with high-quality lifting gears of the reliable AK series.

4.4.1

Motor

Type of chain hoist

Pneumatic motor

70/06AP, 70/06AP-EX

28/06AP, 28/06 AP-EX

29/06AP, 29/06AP-EX

29/06APL Big Bag, 29/06APL Big Bag-EX

4.4.2

Gear

Lifting gear with ventilation screw

AK 4-8 Precision Spur Gear

AK9+10 Precision Planetary Gear

Trolley gear

Combination of worm gear and motor

Closed design - ventilation not necessary.

4.4.3

Control

Control switch with emergency stop

Classification of control according to lifting gear sizes

Kind of control

Standard

Option

Indirect control

AK4-10

--

Direct control

--

AK4

4.4.4