5.52.290.00.01.08

9

DANGER!

The overload protection serves exclusively to protect against damage to the device due to overloading

when moving loads. Its function must not be integrated into the operational work process!

Control

▫ Low voltage control (direct control depends on the kind of unit)

▫ Indirect control with phase sequence relay. The phases must be exchanged if the turning direction is

wrong.

▫ Units with limit switch are fitted with low voltage control.

▫ Radio control is available as option.

Control switch

▫ Control switch suitable for single hand use.

▫ The control switch housing is made of shock- and fracture-proof plastic.

▫ The control cable is fitted with stress-relief rope (not applicable for radio control).

▫ 2 step buttons for 2 wire rope speeds

Overheat protection electric motor

Default

Optional

Electro-EX

PTO

*

PTC

**

PTC

**

*

Thermocouple´

**

PTC thermistor with tripping device

Disengaging clutch (as option)

The disengaging clutch separates the drum from its drive. The clutch is actuated by a hand lever which is

locked by a spring-pin. Before operation, this spring-pin must be pulled by hand and hold until the hand lever

has moved some steps. It engages automatically after the switch operation has ended.

When the clutch is disengaged it is possible to pull the uncharged wire rope off the drum by hand. Should

there be an after-run of the drum, brake it with the foot brake.

CAUTION!

The foot brake must not be used to brake loads! This is not possible (if normal forces act). Unintended

switching is also prevented.

4.4.1

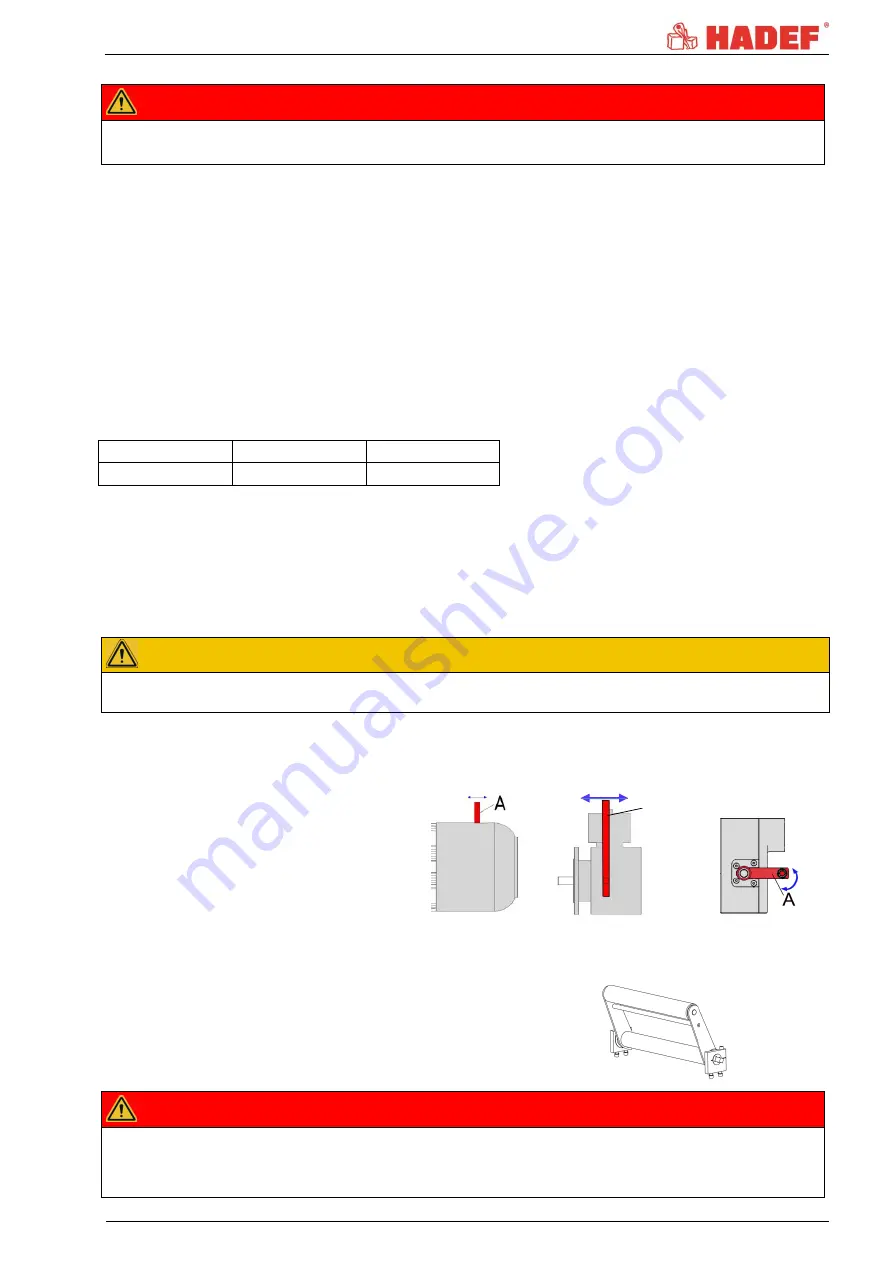

Emergency brake release - hoist (option)

Manual emergency brake release for

lowering the load in case of power

supply failure by means of lever (A).

Electric Electric-EX Pne EX

Illustrattion. 1

Pressure roller (as option)

The pressure roller prevents the skipping of rope

windings, when the unloaded rope will on- or

unwinded.

The

respective

rope

layers

will

pressed

functionally correct .

Illustration 2

DANGER!

The following is not allowed:

Disengaging under load.

Manipulation of the disengaging device.

A