14

5.52.157.00.01.05

11.5

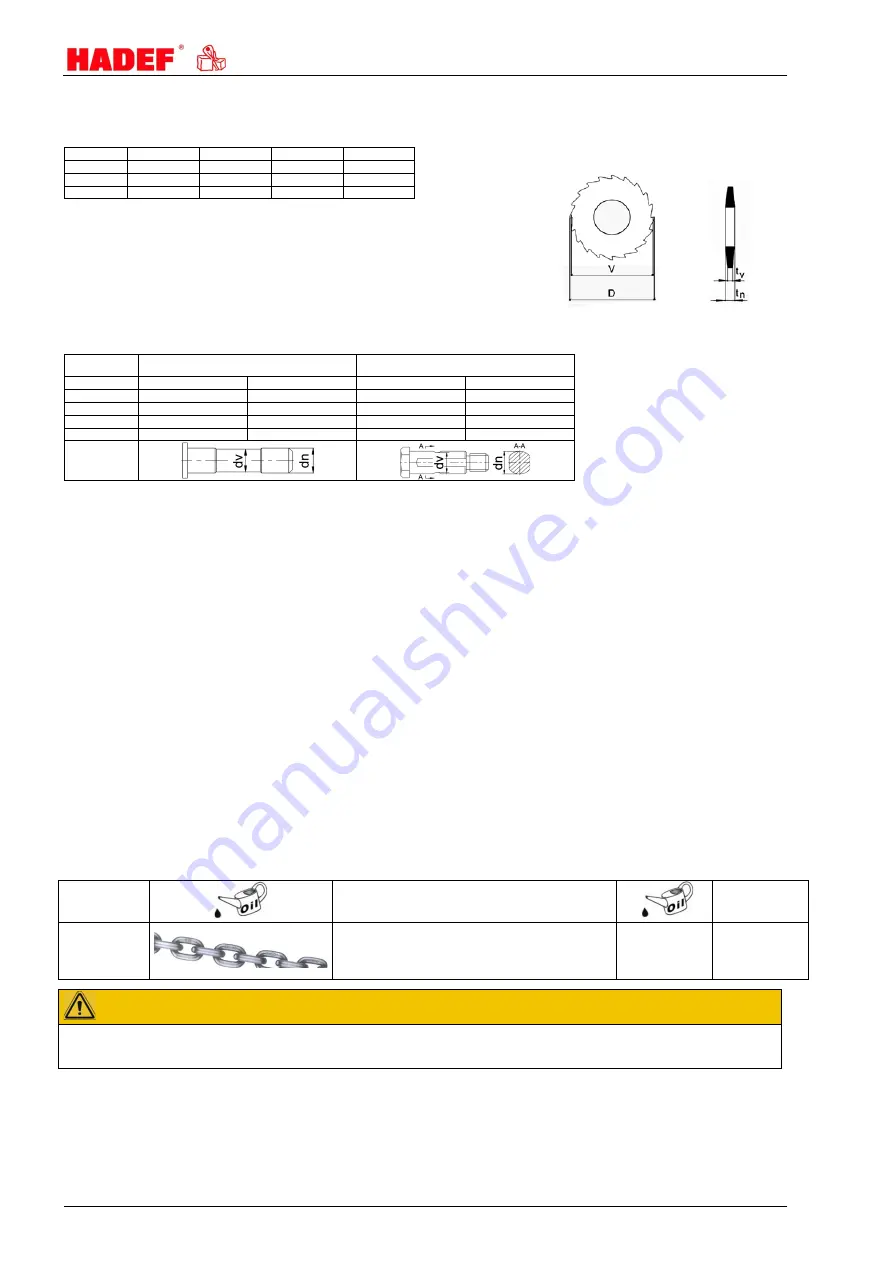

Checking – Brake System

Ratchet wheel (A) and brake linings (B)

D

V

min

tn

tv

min

A 2x B

kg

mm

mm

mm

mm

750

64

61

3,5

3

1500-6000

74

71

3,5

3

11.6

Checking – Suspension and load hook bolt

Suspension bolt

Load hook bolt

dn

dv

min

dn

dv

min

kg

mm

mm

mm

mm

750

12

11,1

6,8

6,3

1500

12

11,4

8,7

8,3

3000-6000

16

15,2

13

12,4

12

Service

12.1

Load chain

Wear at the links is mainly due to insufficient maintenance of the chain.

To ensure optimal lubrication of the links, the chain must be lubricated at regular intervals, depending on

usage.

Lubricate the chain with oil that creeps.

Always lubricate the chain when it is not under load so that the oil can wet the links affected by wear. It is

not sufficient to lubricate the chain from the outside, as this will not ensure the formation of a lubricating

film within the links. The adjacent link points must always be lubricated to prevent excessive wear.

If the same lifting operations are carried out constantly, the switching area from a lifting to a lowering

movement must be given special attention.

Thoroughly effected lubrication of the chain will prolong the life of the chain by approx. 20 times,

compared to dry run with unlubricated chain.

Wash dirty chain with petroleum or a similar cleaner, under no circumstances heat the chain.

If there are environmental influences that foster wear, such as sand, a dry lubricant should be used, e.g.

graphite powder.

When lubricating the chain’s condition of wear should be checked.

CAUTION!

Do not use grease for lubrication of load chain.

Without lubrication, manufacturer's warranty and/or liability will be void.

Use

Recommendation

Interval

Load chain

oil for example: FUCHS RENOLIN PG 220

or special chain lubricant

Use

NO

grease!

0,2 l

3 month