15

Application

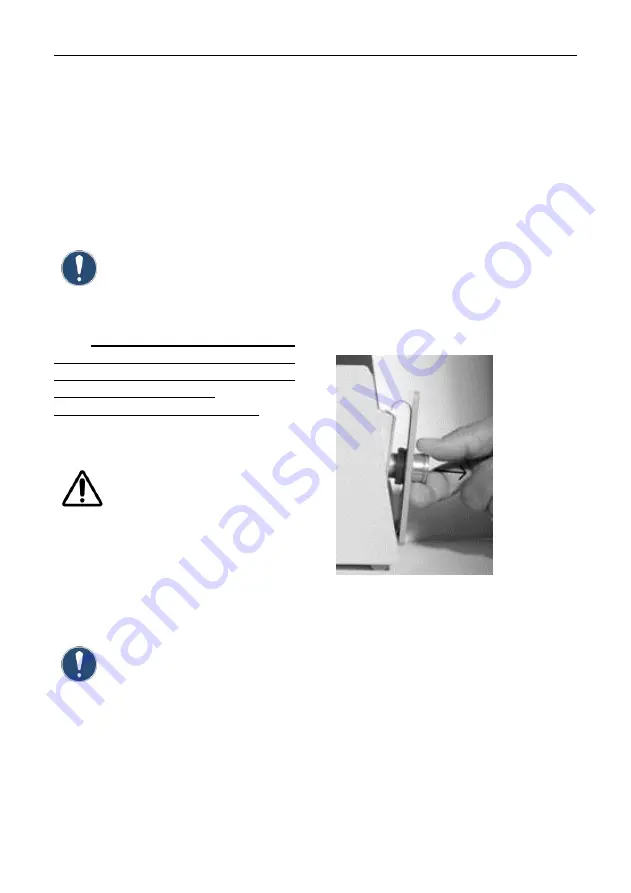

Infilling the spray liquid

Switch off the device. Pull out the

spray tank on its handle. Hold the

cover of the tank in hand and un-

screw the tank.

Now fill it with distilled water and

anti germ liquid (e.g. AQUAHY item

no. 8555).

Do not exceed the maxi-

mum level when filling

the tank.

Now turn the tank cover back on the

tank. While screwing back the cover

on the tank, make sure that is

closed correct. Otherwise there will

no pressure be build up.

Put the tank back in the housing.

Switch on the power switch in the

rear of the unit.

Attention:

Never use tap

water. (Danger of calcifi-

cation). Also do not use

explosive or combustible liquids e.g.

alcohol.

Note:

The filter in the tank (item no.

3479) should be fully under pres-

sure; otherwise no water will be

sucked in.

The water filter has to be

fully under water, otherwise

no water will be sucked in.

Mounting/Changing the

filter

Remove cover plate with filter

(Art.5115). Now the filter can be

pulled from the plate and be

changed. Never work with full filter

or without filter. Put up cover plate.

The cover plate must lie flat but

may move a little. It fits tightly when

the suction cleaner is in operation.

As an option you may also use the

micro filter (Art. No. 5179) instead

of paper filter 5115.

Insert the bur

The handpiece is equipped with a

chuck which can hold all burs with a

diameter of 2.35 mm and usually

are used in the fields of podiatry. To

open the chuck, push the black

knob forward with your thumb and

leave it there. Now insert the tool as

far as possible. Pull back the black

knob and the tool will be clamped.

Summary of Contents for Argos 2

Page 1: ...Art No 0572 FB 04 278 Rev 0 Date 10 05 2016 Manual Argos 0572...

Page 14: ...14 Application...

Page 26: ......

Page 27: ......

Page 28: ...hadewe GmbH Grambartstra e 10 30165 Hannover Germany info hadewe de www hadewe de...