12

Equipment Specifications

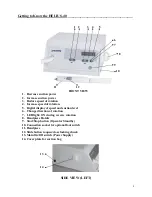

Control Unit “HELIUS-40”

Weight: 4.4kg (9.7lbs)

Measurements: W257xH140xD257mm (10.1”x 5.5”x 10.1”)

Power supply: 115V

∼∼∼∼

. AC, 50/60Hz

Output: 550W

Fuse Pri. F1: 4.0A delayed-action safety fuse

Fuse Pri. F3: 630mA delayed-action safety fuse

Fuse Sec.: Thermal fuse

Protection Class 1

Voltage potential (output) 5-27V

Suction capacity: 300-600 mmWs

Noise level: <64dBA at 1m distance

Suction-Handpiece

Weight: 160g

Length: 160mm (6.3”)

Handpiece diameter: 17.5mm – 22mm (.7” - .9”)

Power supply: 5-27v/DC

Speed range: 7000 – 40,000rpm

Manufacturer Information

Made in Germany by: HADEWE

Service and Support in North America:

Thomas Machinery Ltd.

Tel: 519-824-2315

Fax: 519-824-9691

E-mail: info@rotatool.com

Toll Free Customer Support: 800-361-3079