8

Maintenance & Care_________________________________________________

Monthly Cleaning and Maintenance

Every 200 operating hours a number of important maintenance procedures should be done

to ensure the long term performance of this equipment

1.

Exchange the Control Unit filter (Art. 3752).

a.

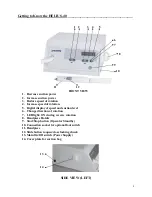

Turn the Control Unit OFF using button at back of

equipment (13).

b.

Remove the suction cover plate (14) and remove the filter

bag (described on page 7)

c.

Remove the old filter from the inside of the Control Unit

and slide a new one into the holder (see picture)

d.

Replace the filter bag and close the over plate.

2.

Exchange the Sealing Washer at the top of the handpiece. This white washer needs

to be changed to prevent dust from entering the handpiece and causing damage.

a.

Use the included Spanner tool to screw off the head

(tip) of the handpiece (see picture below).

b.

Pull out the washer using pincers.

c.

Push a new washer into place from above into the top

of the head (see picture at right).

3.

Cleaning the Handpiece

a.

Screw off the head (tip) of the headpiece with the spanner (see picture above).

b.

Clean the inside of the handpiece and top with a soft dry brush.

c.

Open the chuck by pushing the slide-button forwards on the handpiece.

d.

Place spanner tool (Part #5374) into shaft and hold firmly. Insert pointed end

of key (Part #5361) into chuck and screw out chuck (see picture below).

e.

Clean the chuck (see instruction on next page) and brush out any dust from

the handpiece.

f.

Reassemble the handpiece in reverse order. Ensure that the slide-button is

set to open (in the forward position) during assembly and that the chuck is

firmly tightened.