MONTHLY (IF IN REGULAR USE)

1.

Check ghtness of moun ng bolts, and head and column securing set

screws.

Check the drive belt for wear, and replace if frayed or damaged.

Blow out with compressed air, or vacuum clean out, any dust that may have

accumulated in the motor fan vents.

Apply a thin coat of wax paste or light oil to the table and column, for

lubrica on, and to help prevent corrosion.

If the mains lead is damaged in any way, it should be replaced immediately.

2.

3.

4.

LUBRICATION

All bearings are packed with grease at the factory and require no further

lubrica on.

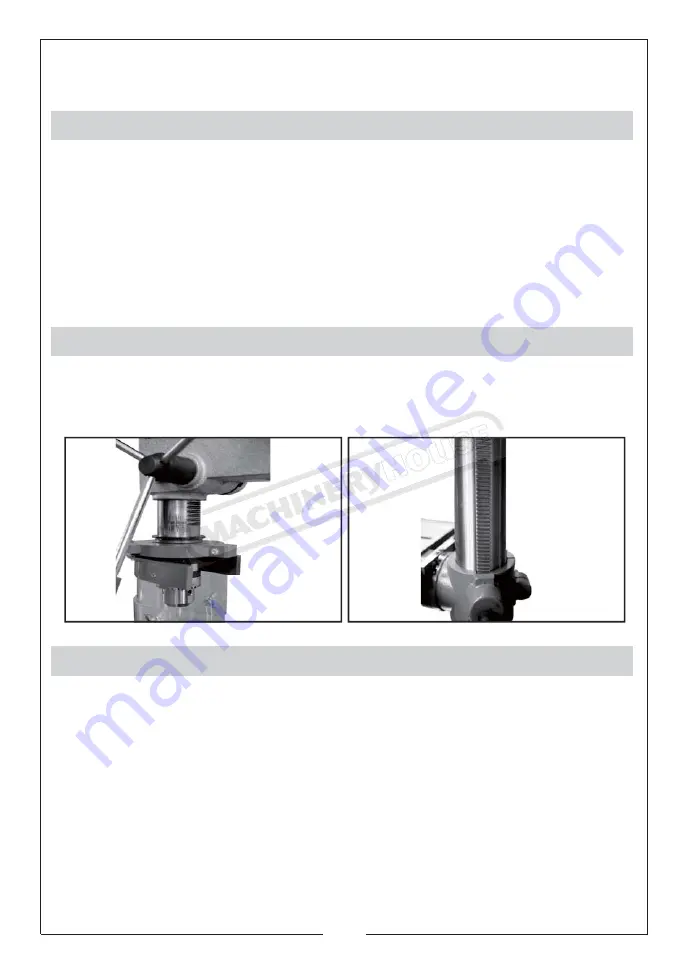

Occasionally, lubricate the quill sha assembly and rack with light oil if required.

AFTER USE

Remove all swarf from the machine and thoroughly clean all surfaces.

Components should be kept dry, with machined surfaces lightly oiled.

Always remove drill bits, and store in a safe place.

Please refer to the trouble shoo ng chart on pages down. If you are unable to.

rec fy any faults, please contact your local dealer for assistance.

Fig.44

Fig.45

18

Page 19

Instructions Manual for PD-440 (D598)

19/11/2015