2

Assembly instructions

Before un-crating the machine or the table assembly, please ensure the serial numbers on

the 2 x crates correspond with each other.

If not please contact the point of purchase and advise them serial numbers supplied

CAUTION

Must be taken when un-crating of sharp edges of sheet metal corner supports and nails

Remove lid off the large main saw box (1 of 2 ) and then the sides one by one

Remove the lid of the long box (2 off 2)

Open rear blue door of the main saw stand to gain access and remove the cardboard box with blades

operation instructions, tools and other small parts and accessories.

Remove all other packing and accessories.

Read safety and operation instructions supplied

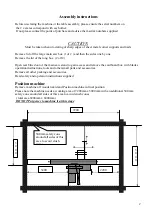

Position machine

Remove machine off wooden skid and Position machine in final position

Please note the machine needs a working area of 7200mm x 5000mm with an additional 500mm

safety zone around all sides of this area to avoid crush zones

( total area 8200mm x 6000mm )

DO NOT Put power to machine it at this stage

5

0

0

0

7200

3400

2200

3

4

0

0

500mm safety zone

around all sides of this

area to avoid crush

zones