P1

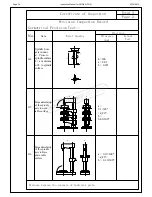

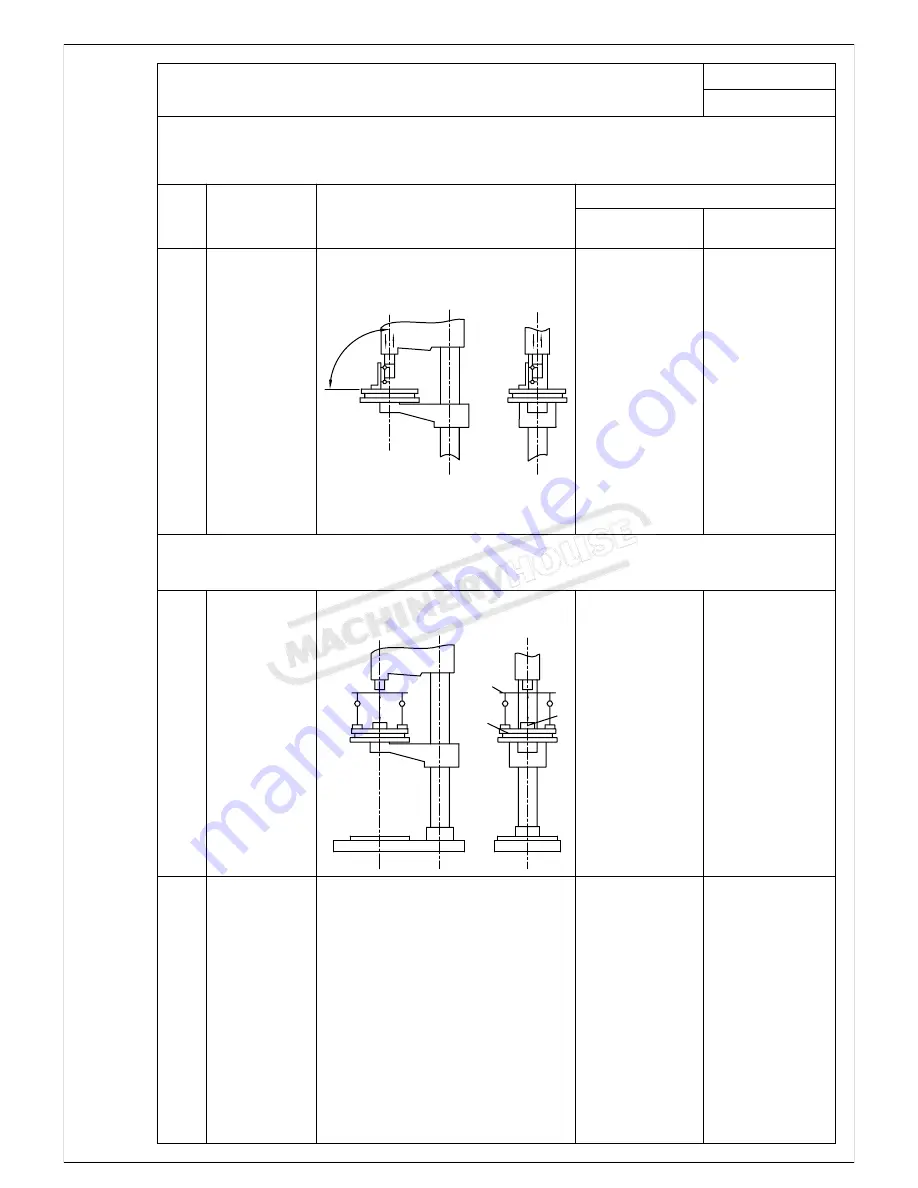

F=5000N

2/1000

a.0.1/300

(

a≤90

°

)

b.0.1/300

G7

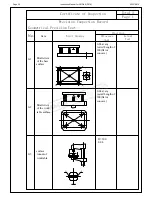

Work Acuracy:

a

F

M

B

A

b

Actual

Test

Precision

Allowance

(mm)

Page 3

Total 3

Certificate of Inspection

Precision Inspection Record

Germetrical Precision Test:

Item

No.

Brief Drawing

Perpendicularity

of the vertical

movement of

spindle sleeve

to work table

surface

The change of

Perpendicularity

of spindle

axis to work

table surface

under the

axial force.

α

a

b

Page 31

Instruction Manual for GHD-50 (D178)

23/12/2014