14

OPERATION MANUAL

F

ig

. 4.6

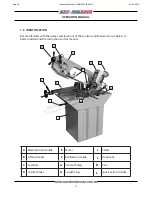

4.2 COOLANT SYSTEM

The sawing movement produces high temperatures

at the edge of the blade due to the friction generated.

The blade must therefore be cooled during operation.

Using a suitable lubricant or cooling agent leads to

better results and longer saw blade life. (Fig. 4.6)

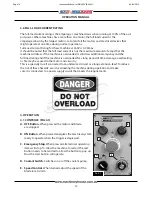

The coolant is delivered through two taps situated on

the blade guide assemble.

To start the coolant turn the switch on the control panel

(D in Fig.4.1) and press and hold the trigger switch, then

adjust the taps. (Fig.4.7 & 4.8) To much flow at the nozzle

will make a mess of the work area and cause it to be-

come unsafe, but to little will cause the blade to over-

heat, causing the blade teeth to load up and break.

F

ig

. 4.7

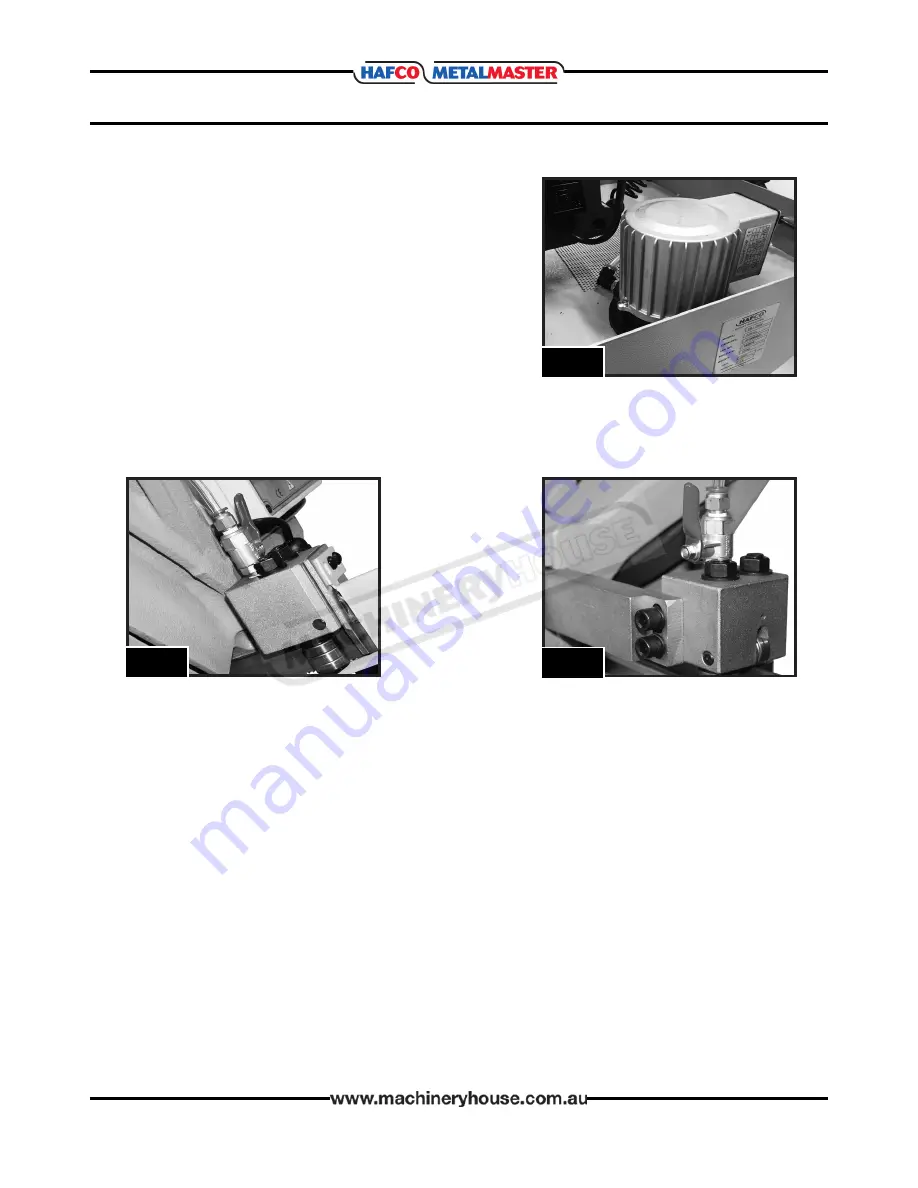

Soluble Oils

The most common of all water-soluble cutting fluids, soluble oils (also known as emulsifiable

cutting fluids) are typically 50 percent oil before dilution. When mixed with water, they form a

milky emulsion that is an excellent choice for general purpose cutting. They are, however, prone

to “Monday morning stink”–a foul-smelling odor from microbiological growth of fungus and

bacteria that can grow in your coolant sump if not properly maintained.

Synthetic Fluids

As you can probably guess from the name, synthetics contain no oil, using various polymers

and chemical compounds to replicate oil’s natural lubricity. They reject tramp oil, so they tend

to be the cleanest of all cutting fluids, but are often the least lubricious. They are commonly

used in grinding applications, but proponents suggest that synthetics can be tailored to

virtually any metalworking operation, especially metal cutting band saws.

HAFCO recommend that

Synthetic

cutting oil be used available in two sizes.

5 Ltr Order Code S090

20 ltr Order Code S091

F

ig

. 4.8

COOLANT SELECTION

Page 14

Instruction Manual for EB-260V (B062V)

04/04/2019