9

OPERATION MANUAL

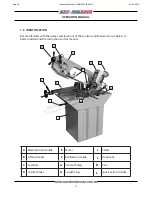

2.3 LIFTING INSTRUCTIONS

On the day that the machine arrives, make sure that a crane with sufficient capacity is available

to unload the machine from the vehicle. Ensure access to the chosen site is clear and that doors

and ceilings are sufficiently high and wide enough to receive the machine.

To handle the machine, the slings should be positioned so the machine is level when lifted.

When using slings please take note of the sling angle and the loads that apply.

LIFTING POINTS

Use only the 4 eye bolts supplied with the machine to attach the slings. When lifting the ma-

chine only certified lifting slings should be used. Ensure that when lifting, the machine does not

tip over. Check that the lifting slings do not interfere with the hydraulic pipes or electrical con-

duits. Failure to follow these instructions could cause damage to the machine.

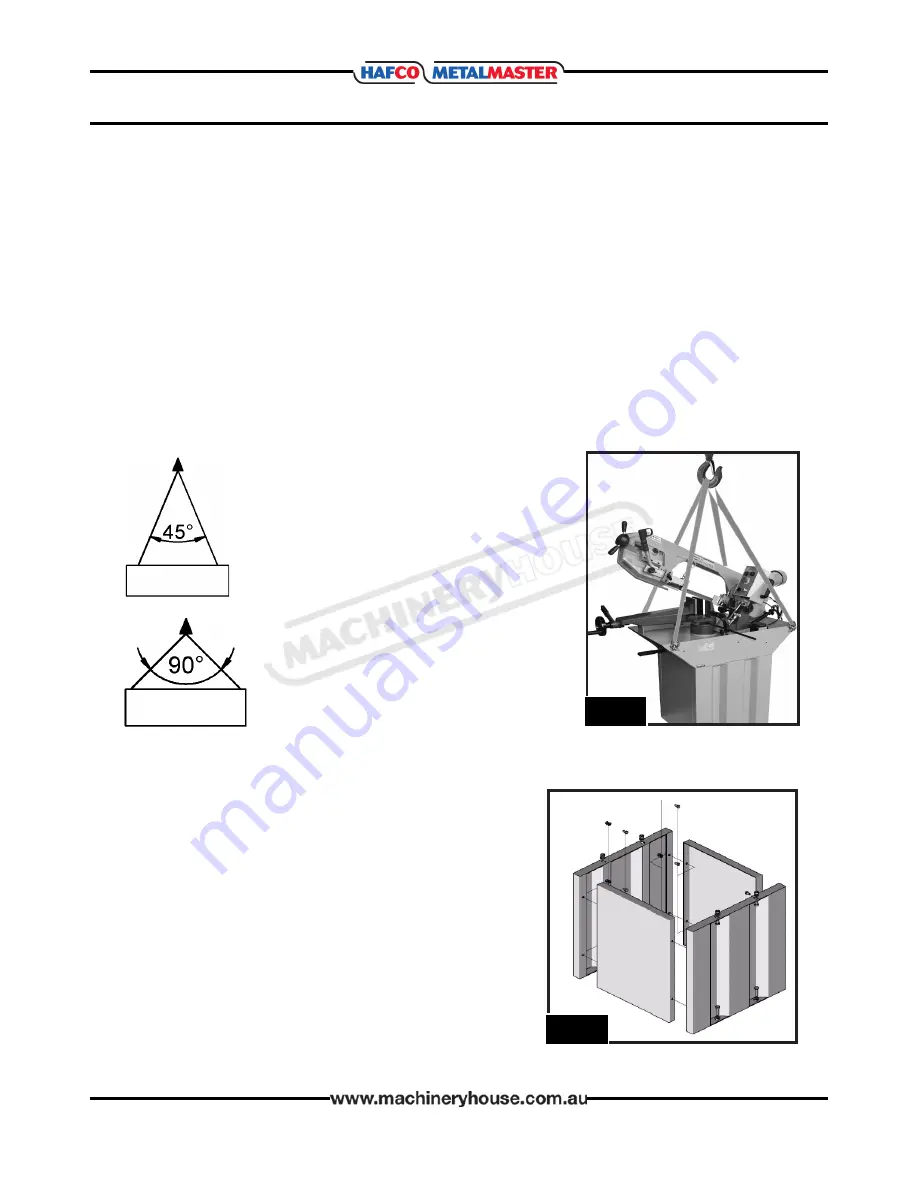

When the slings are at a 45° angle then each

sling is carrying the equivalent of 50% of load

weight. (Fig.2.1).

When the slings are at a 90° angle then

each sling will have a weight equal to 75%

of the load on each sling.(Fig 2.2)

Note!

The manufacturer recommends not

to exceed 90° angle

Fig 2.2

Fig 2.1.

F

ig

. 2.3

2.4 MACHINE STAND ASSEMBLY

To assemble the stand, find a flat even space with plenty

of room to layout the side panels.

q

Fit the side panels of the machine stand as shown in

the diagram Fig. 2.4.

q

Place the metal belt saw on the machine stand.

q

Bolt the metal belt saw to the machine stand.

q

Bolt the drip pan to the machine stand

F

ig

. 2.4

Page 9

Instruction Manual for EB-260V (B062V)

04/04/2019