15

WARNING! Failure to install the screws or fixing device in

accordance with these instructions may result in electrical

hazards.

Do not use with a programmer, timer, separate remote control

system or any other device that switches on automatically.

When handling the hood do not put hands within the range of

action of the pull-out suction panel (trolley)

The hood is equipped with safety switches which inhibit

operation when the front filter panel is unhooked.

With the intention of constantly improving our products, we

reserve the right to make all the changes in their technical,

functional or design characteristics, deriving from their

evolution. In case of the version with external motor, the

normal operation of the hood requires the use of a suction unit

(external motor) of the same manufacturer.

This appliance is marked according to the European directive

2012/19/EC on Waste Electrical and Electronic Equipment

(WEEE). By ensuring this product is disposed of correctly, you

will help prevent potential negative consequences for the

environment and human health, which could otherwise be

caused by inappropriate waste handling of this product.

The symbol

on the product, or on the documents

accompanying the product, indicates that this appliance may

not be treated as household waste. Instead it should be taken

to the appropriate collection point for the recycling of electrical

and electronic equipment. Disposal must be carried out in

accordance with local environmental regulations for waste

disposal.

For further detailed information regarding the process,

collection and recycling of this product, please contact the

appropriate department of your local authorities or the local

department for household waste or the shop where you

purchased this product.

Appliance designed, tested and manufactured according to:

• Safety: EN/IEC 60335-1; EN/IEC 60335-2-31, EN/IEC

62233.

• Performance: EN/IEC 61591; ISO 5167-1; ISO 5167-3; ISO

5168; EN/IEC 60704-1; EN/IEC 60704-2-13; EN/IEC 60704-3;

ISO 3741; EN 50564; IEC 62301.

• EMC: EN 55014-1; CISPR 14-1; EN 55014-2; CISPR 14-2;

EN/IEC 61000-3-2; EN/IEC 61000-3-3. Suggestions for a

correct use in order to reduce the environmental impact:

Switch ON the hood at minimum speed when you start

cooking and kept it running for few minutes after cooking is

finished. Increase the speed only in case of large amount of

smoke and vapour and use boost speed(s) only in extreme

situations. Replace the charcoal filter(s) when necessary to

maintain a good odour reduction efficiency. Clean the grease

filter(s) when necessary to maintain a good grease filter

efficiency. Use the maximum diameter of the ducting system

indicated in this manual to optimize efficiency and minimize

noise.

Use

The hood is designed to be used either for exhausting or filter

version.

Ducting version

In this case the fumes are conveyed outside of the building by

means of a special pipe connected with the connection ring

located on top of the hood.

Attention

! The exhausting pipe is not supplied and must be

purchased apart.

Diameter of the exhausting pipe must be equal to that of the

connection ring.

Attention! If the hood is supplied with active charcoal filter,

then it must be removed.

Filter version

The aspirated air will be degreased and deodorised before

being fed back into the room.

In order to use the hood in this version, you have to install a

system of additional filtering based on activated charcoal.

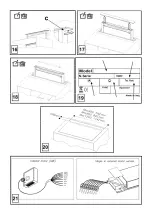

Note:

The recycled air in the charcoal filter is sent back to the

kitchen through a duct which conveys air on a side of the

cabinet (

Picture 11

).

Non-return valve locking

Attention, before connecting the flexible air outlet pipe make

sure that the non-return valves of the suction unit can freely

rotate (

Picture 12

).

The models with no suction motor only operate in ducting

mode, and must be connected to an external suction device

(not supplied).

The connecting instructions are supplied with the peripheral

suction unit.

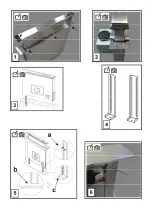

Installation

Note:

The installation must be performed so that accessibility

to the hood and its electronic components is always ensured

for possible technical assistance interventions.

When installing the product, it is recommended to keep a

minimum distance of 400mm between the worktop and any

components laid on top of the hood.

This is to let the suction panel move upwards (opening) and

downwards (closing) without any obstacles, and to facilitate

access to the hood controls on the panel.

WARNING:

Put the metal box containing the electronic

components at a distance not shorter than 65 cm from the gas

hob or 65 cm from the hood suction point.

The minimum distance between downdraft edge and hob

edge must be at least 50mm.