DH-222 INSTALLATION INSTRUCTIONS

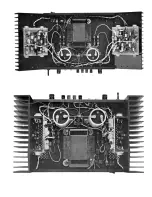

Disconnect AC power from the amplifier, and remove all con-

necting cables. Wait 5 minutes to allow capacitors to discharge

before proceeding with disassembly.

Remove all 8 screws between the fins of each amplifier module

so that the cover may be removed, and the modules tilted out-

wards for easier access.

Unsolder the pair of twisted wires connected to holes 1 and 2 at

the top of the

right

channel PC-19 circuit board. The right

channel is the one nearest the power switch. This pair must

also be unsoldered from the right input socket on the back

panel, because it will be more convenient to use lighter gauge

wiring.

Prepare a 6%” red wire, and a 6 1/2" black wire. Start with the

black wire 1/2"”longer than the red wire, and twist them together

uniformly throughout their length. At the end where the black

wire projects, connect it to the

short

lug of the right input sock-

et. (S-2). Be sure the existing wire to the adjacent ground lug is

properly connected. Connect the corresponding end of the red

wire to the long lug of the input socket. (S). Place this pair off to

the right edge.

Prepare a 5%” red wire, and a 5%” black wire. With the ends

even, twist these together and connect ,the red wire to hole #l

at the top of the right channel PC-19 circuit board.

(S)

Connect

the black wire to hole #2. (S).

Prepare a 20”green wire. Cut a 20” black wire, but remove the

insulation from only one end. Starting with the bare end of the

black wire 1/2”longer than the green wire, twist these together.

At the far end, where the black insulation has not been re-

moved, the black wire will not be connected, but instead will be

secured by wrapping it in a tight circle around the green wire a

short distance from the bare green end. It is very important

that no bare wire be visible from the black insulation. The

single green wire is to be connected near the center of the lefi

circuit board to the hole designated “B”, located just below the

bias adjustment potentiometer. t

S).

It must be securely sol-

dered, but be careful that you do not damage adjacent compo-

nents.

Making sure that no wires are pinched between the module

and the chassis in the process, reinstall the left module to the

chassis with 4 sheet metal screws.

Select the switch and its 2 nuts, lockwasher and indexing flat

washer, and the switch mounting bracket. Install one nut all

the way onto the switch collar, and follow it with the indexing

washer with its lugprojecting towards the handle lever. Mount

the switch on the bracket so that the lever points in the direc-

tion of the bracket flange, and the indexing lug engages the

locating hole in the bracket. Secure it with the lockwasher and

the second nut.

9

Select the two machine screws and nuts, and install the switch

bracket between the two transistors at the rear of the right

module, so that the switch lever points towards the fins.

10

Select the 3000 ohm resistor and trim its leads to 1/2" Connect it

between switch lugs #4 and #5. Solder only lug #5.

11 Select the red and black pair from the right input socket and

12

13

I4

I5

16

connect the black wire to switch lug #3. Do not solder this con-

nection yet. Connect the red wire to switch lug #1. (S).

Select the red and black pair from the right channel circuit

board holes 1 and 2. Connect the black wire to switch lug #3.

(S-2). Connect the red wire to lug #2. (S).

Select the green and black pair and separate the wires for

about 1%“. Connect the green wire to right circuit board hole

“A”. (S). Connect the black wire to hole “E”. (S). Hole “A” is

located in line with the switch about 1 1/2” from the rear edge of

the board. “E” is located

1/2”

below hole 2, near the top of the

board.

Place the green and black pair towards the rear of the module,

and down past the midline of the switch. Where it passes lug

#5, approximately

the end of the wires, cut

only

the

green wire. Strip each end 1/4" Connect the short green section

to switch lug #4. (S-2): Connect the longer green wire from the

left board to switch lug #6. (S).

Be careful no wires are pinched as you reinstall the right mod-

ule to the chassis with 4 screws. Place the long green and black

pair under the rear lip of the chassis. The pairs to the top

eyelets on each board, and to the connections in the center of

the board should be kept at least off the board, where they

are clear of the components. Make sure the unconnected black

wire end near the left circuit board cannot touch any compo-

nents.

The switch lever should be placed in the upper position for

monophonic operation. In the lower switch position, the

amplifier functions as a conventional stereo amplifier. Rein-

stall the amplifier cover with the remaining 8 screws.