4200 Rim Exit Device

Installation Instructions

I-ED01625

Rev -, Rev Date: 07/23/13

Page

3

of

4

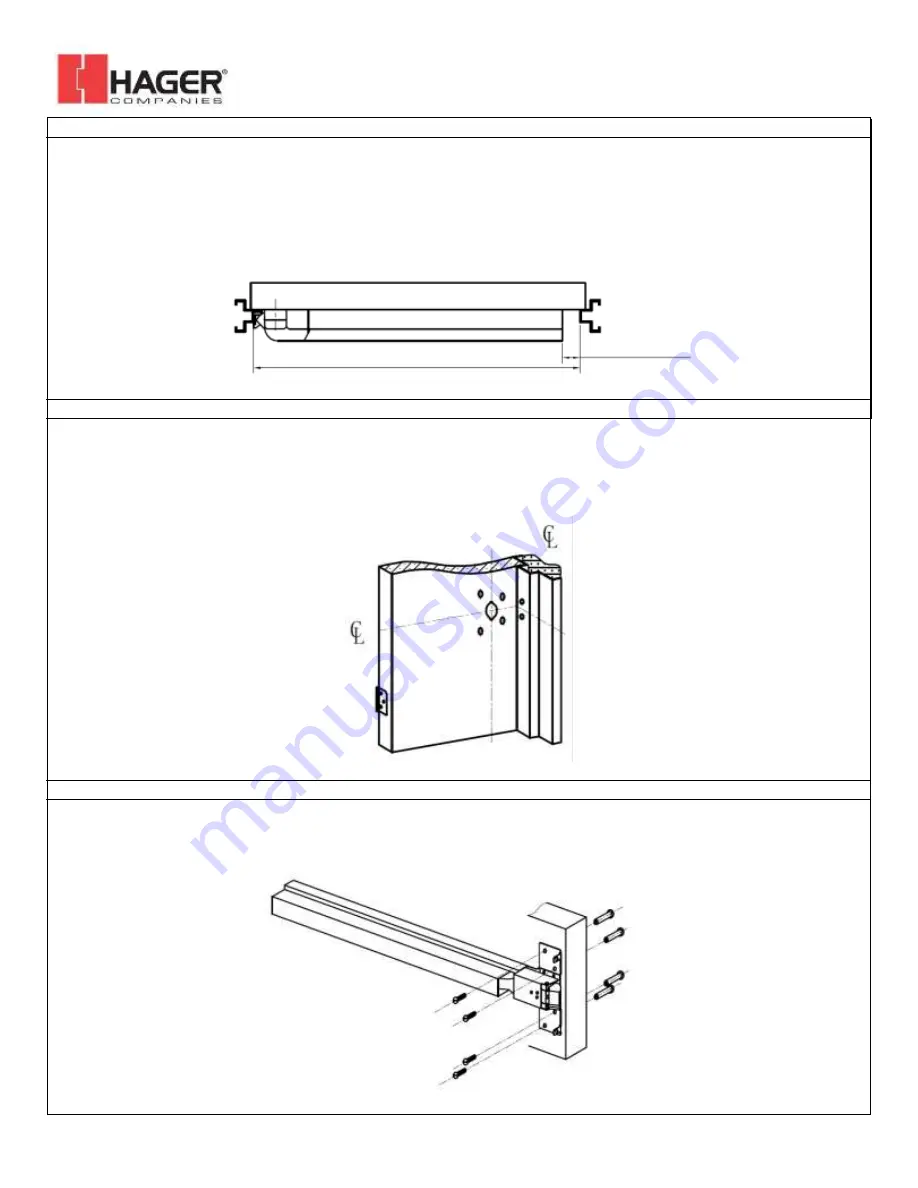

1.

Prep Exit Device For Door Size

1)

Prep for door width.

-

The 4’ exit device will work for openings from widths of 650mm to 1828mm. However, for openings narrower than

1100mm, the device must be cut.

-

The 3’ exit device will work for openings from widths of 650mm to 1524mm. However, for openings narrower than

890mm, the device must be cut.

-

The recommended overall length of the exit device, for a standard single door, is equal to the opening width minus

80mm. Cut with a hack saw or metal cutting saw blade and deburr edges (do not grind cut as this may damage the

finish).

2.

PREPARE DOOR

1)

Mark vertical and horizontal centerline (

℄

) for desired setup using the dimensions on page 1 of this instruction set.

2)

Tape drilling templates #T-ED01671 on the door, using the vertical and horizontal centerlines.

3)

Drill holes to sizes required for desired mount hardware for device and strike.

a.

Only drill the outer holes for the strike on initial door prep. Drill and install the middle screw after installation and

adjustment.

4)

If using outside trim, prepare door using separate trim direction sheet provided with trim

3.

Hardware Installation

1)

If using outside trim, mount trim per directions in trim box.

2)

Fix device with provided Through Bolts or Mounting Screws.

Opening Width

~40mm

- from edge of frame

to end of cut

device, not end cap.