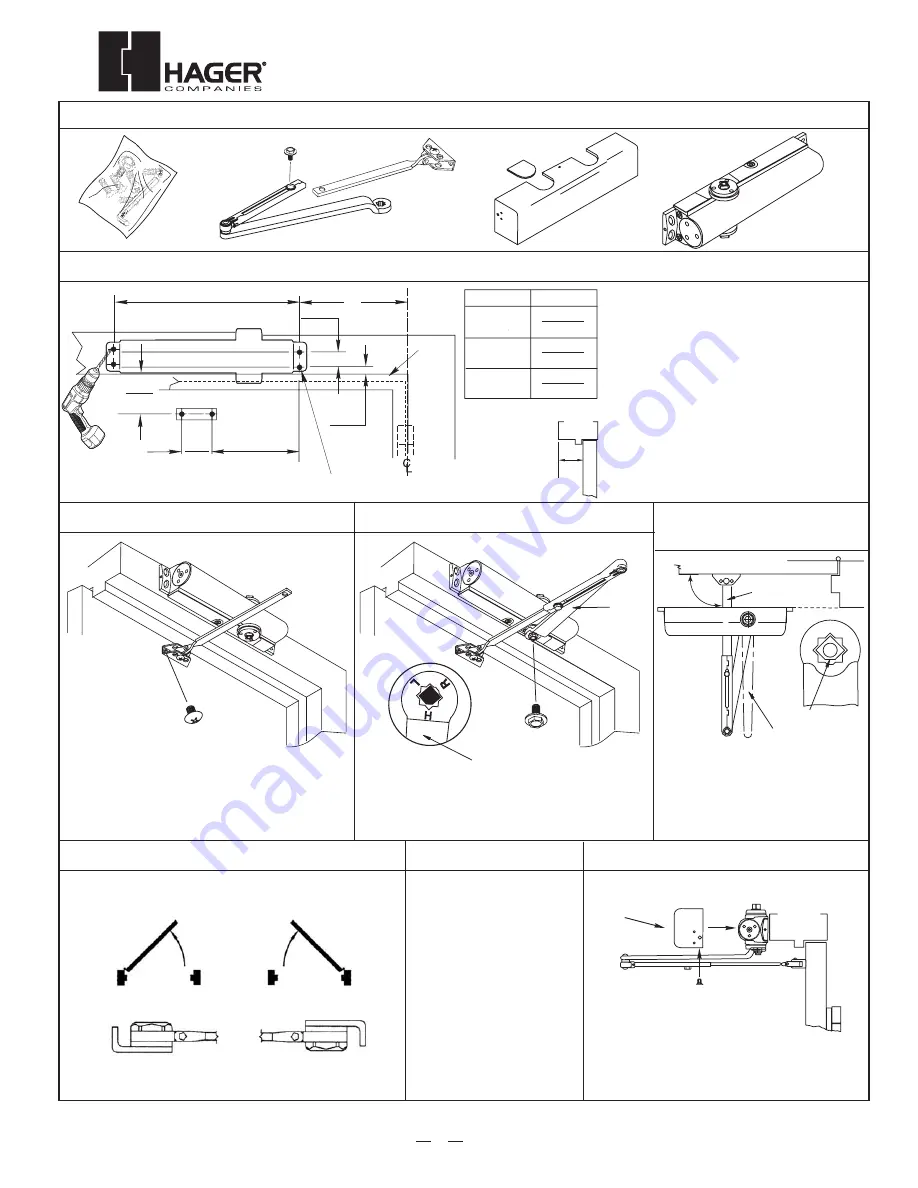

12"

(305mm)

Top of

Frame

A

3/4"

(19mm)

1/2"

(13mm)

1-7/8"

(48mm)

1-3/4"

(44mm)

5-1/2"

(140mm)

L

H

R

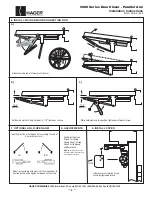

1. PARTS

3. INSTALL CLOSER

2. MARK AND DRILL HOLES (

Right Hand Shown)

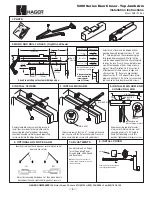

4. INSTALL MAIN ARM

5. INSTALL MAIN ARM AND

CONNECTING ROD

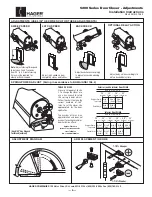

7. ADJUSTMENTS

8. INSTALL COVER

COVER

MAIN ARM

CONNECTING

ROD

MAIN ARM

Select hand of door and the degree of door

opening. Separate template sections “A” and

“B”. Fold template on the corresponding line

for desired degree and hand. Match this line

with the hinge edge of door and attach template

to door. Be sure “Frame” line on template lines

up with the top edge of door. Using a square,

project “Closer Projection Line” on section “A”

of template onto frame and use to align and

attach section “B”. Be sure to align bottom

edge of section “B” with edge of frame. Mark,

prep and drill/tap 1/4"-20 holes for connecting

rod shoe and closer body mounting screws.

Remove template and use mounting screws to

install the closer body to the top jamb and the

connecting rod shoe to the door. Closer body

should be oriented so that the speed regulating

valves are toward the hinge stile of door.

A longer connecting

rod is required for

reveals greater

than 4" (102mm)

Slide cover over closer body and

secure by tightening screws.

Orient main arm so that the “H”, located on the main

arm, lines up with the flat on the spindle. Press arm

down on spindle and secure with spindle bolt.

Slide connecting rod into forearm

of main arm. Rotate main arm until

connecting rod is at a 90˚ angle to

frame. While holding arm in this

position, tighten down forearm screw.

Door Opening

Dimension “A”

To 100

7-1/2"

(191mm)

6"

(152mm)

4-1/2"

(114mm)

101 to 130

131 to *180

*Door/Wall/Hardware/Jamb

conditions permitting

Speed regulating valves toward hinge edge.

5200 Series Door Closer - Top Jamb Arm

Installation Instructions

Meets ANSI A156.4

5

HAGER COMPANIES

139 Victor Street, St. Louis, MO 63104 • (800) 325-9995 • Fax (800) 782-0149

Reveal

FRAME

WHEN ASSEMBLING TO SPINDLE

POSITION OF MAIN ARM

RIGHT HAND DOOR

90

RIGHT

ANGLE

PINION FLAT

See Adjustments on Page 6

for setting Spring Power,

Sweep Speed, Latch Speed,

and Backcheck.

NOTE:

Do not fully unscrew valves or

hydraulic fluid will leak and closer will no

longer be functional.

6. OPTIONAL HOLD-OPEN ARM

Identify direction of hold-open nut according to hand of

door and mount arm.

Adjust by loosening hold-open nut, then open door to

desired position and tighten hold-open nut securely.

LH

RH