6LE007316Ab

Preliminary operations

Check the following upon delivery and after removal

of the packaging:

• Packaging and contents are in good condition.

• The product reference corresponds to the order.

• Contents should include:

- 1 ATSE controller

- 1 set of terminals connectors

+ 1 set of door mounting clips

- 1x Quick Start instruction sheet

This Quick Start is intended for personnel trained in

the installation and commissioning of this product.

For further details refer to the product instruction

manual available on www.hager.com.

This product must always be installed and

commissioned by qualified and approved personnel.

Maintenance and servicing operations should be

performed by trained and authorised personnel.

Do not handle any control or power cables connected

to the product when voltage may be, or may become

present on the product, directly through the mains or

indirectly through external circuits.

Always use an appropriate voltage detection device

to confirm the absence of voltage.

Ensure that no metal objects are allowed to fall in the

cabinet (risk of electrical arcing).

Failure to observe good enginering practises as well

as to follow these safety instructions may expose the

user and others to serious injury or death.

Installation and commissioning controller HZI815 / HZI825

Step 1

Installation

Step 2

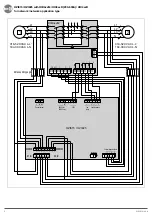

Connection

Step 3

Programming

z

Automatic Transfer Switching

Equipment Controller for HIB4xxM

HZI815 / HZI825

Risk of electrocution, burns or injury to persons

and / or damage to equipment. Risk of damaging

the device In case the product is dropped or

damaged in any way it is recommended to

replace the complete product.

6LE007316Ab

1

6LE007316Ab

5

92

138

1,5 - 3

Clac !

Hager Electro S.A.S., Boulevard d'Europe, B.P. 3, 67215 OBERNAI CEDEX, France - www.hager.com

OCOM 140658

Hager 02.21

6LE007316Ab

6

Trouble shooting guide

Definition

Recommended action

Sources are not detected

- Verify that the product is correctly powered on using the power LED.

- Verify that the DIP switch settings are corresponding to your installation.

Positions are not detected

- Verify that the position input cabling is correctly done.

Source LED are blinking

- Verify that the sources are in the voltage range configured through DIP switch or communication.

- Verify that the sources are cabled correctly.

- Verify that the phase rotation is identical on both sources.

Alarm LED is

blinking

Long blinking

- Verify that Neutral of source I is connected to terminals 103/102 and that Neutral of source II is

connected to terminals 203/202. Connected a Phase instead Neutral can damaged definitely the

product.

- Verify that the input 63A-64A is closed.

- Verify that there has not been a problem during a transfer order and validate fault with the AUTO

button.

Short blinking

- Verify that the DIP switches have not changed position or validate the change of position using the

OK button.

COM LED is on fixed (for HZI825 only)

- Verify that Communication settings are set according to your specification.

- Press “OK” for 30 seconds to reset the Communication settings.

- Contact Hager for other information.

DIP switch parameters are not taken into

account

- Check if the alarm LED is blinking.

- Verify that you are in manual mode when changing DIP switch parameters.

- Press the “OK” button for less than 3s to validate the parameter change.

Interface

Start FT

+ΔU/ΔF

[Hyst]

[Hyst]

-ΔU/ΔF

Vn 230 VAC L/N

Un 400 VAC L/L’

Fn 50 Hz

Start RT

Start FT

Start RT

T

Hysteresis & timers

Settings

1. Source 1 availability information (Green fixed when source 1 is present and available

and within threshold limits, green blinking when source 1 is present but outside of

threshold limits, off when under 50 VAC).

2. Switch 1 LED position indication (Green fixed when in position 1).

3. Zero position LED indication (Yellow when in position 0).

4. Load supplied information (Green fixed when load is supplied by an available

source).

5. Switch 2 LED position indications (Green fixed when in position 2).

6. Source 2 availability information (Green fixed when source 2 is present and available

and within threshold limits, green blinking when source 2 is present but outside of

threshold limits, off when under 50 VAC).

7. Auto LED indication (Green fixed when in automatic, blinking when transfer is

ongoing, off when in manual mode).

8. Test LED (Yellow fixed when test on load is ongoing).

9. Configurations dip switches (see settings).

10. Run LED (Green when product is powered).

11. Fault LED (Red blinking – long blink when fault or inhibit is activated (63 A - 64 A

open), short blink when a dip switch parameter has been changed and needs

validation).

12. Fire (Red when fire input is activated).

13. COM LED (yellow blinking when RS communications is ongoing) (for HZI825 only).

14. Change AUTO/MANU pushbutton, press at least 3 seconds to switch from AUTO

to MANU or MANU to AUTO.

15. Remote order to switch positions, controller must be in MANU mode for the

buttons to be active.

16. Test button with two functions lamp test and TEST ON LOAD. To start a lamp test

short press on the test button (<3s) ,press again (<3s) to end test. To start a TEST

ON LOAD, long press on the test button (>3s), when LED (8) is blinking press the

“0” button. To end the TEST on load long press on the test button (>3s).

0DT: Dead Band Timer (time to stay in O position during transfer).

FT: Fail Timer (time which the source can be outside the threshold’s

limits before it is considered lost).

RT: Return Timer (time which the source must be within the

threshold’s limits before it is considered available).

Standards

Product must be in manual

mode (LED 7 OFF) for

configuration changes.

After changing DIP switch settings

press OK button shortly (<3s) to

validate.

Cool down timer fixed and set at 180s.

To reset controller: push >30s

OK button.

* hysteresis value is 20% of settings

IEC 60947-6-1*

IEC 61010-2-201 IEC 61010-2-030

GB/T 14048.11

appendix C

Voltage sensing

50-300 VAC L/N 90-520 VAC L/L’

Operating

voltage

184-300 VAC L/N 318-520 VAC L/L’

Measurement

category

CAT III

Frequency

50-60 Hz

50-60 Hz

50-60 Hz

50 Hz

Overvoltage

category

III

III

III

Uimp

4 kV

6 kV**

* When type tested with IEC 60947-6-1 RTSE

** Test level ; Between SOURCES

Source available

DIP switch

1. Network

A

Three phase network

B

Single phase netwrok

2. Prio Set

A

Priority source 1

B

No priority

3. Order mod

A

Control mode impulse logic

B

Control mode contactor logic

4. ΔU/ΔF

A

Setting: +/- 10% of Nominal Voltage and +/- 5% of Nominal Frequency*

B

Setting: +/- 20% of Nominal Voltage and +/- 10% of Nominal

Frequency*

5. 0DT

A

Load supply down time of 2s (0DT = 2s)

B

Load supply down time of 0s (0DT = 0s)

6. FT

A

Wait time of 3s before source is lost (Fail timer = 3s)

B

Wait time of 10s before source is lost (Fail timer = 10s)

7/8. RT

AA

Wait time of 0min (3s) before source returns (returnstimer = 0min (3s))

AB

Wait time of 3min before source returns (returnstimer = 3min)

BA

Wait time of 10min before source returns (returnstimer = 10min)

BB

Wait time of 30min before source returns (returnstimer = 30min)

MODBUS communication parameters (only for HZI825)

Dec. Address

Word count

Description

Unit

40017

1

HZI825 communication node

address

1 … 247

40018

1

Baud rate

2 : 2400

3 : 4800

4 : 9600

5 : 19200

6 : 38400

40019

1

Serial Data format

1 : 8N

2 : 80

3 : 8E

4 : 70

5 : 7E

40020

1

Stop bit

1 … 2

As standard the baud rate is set to 38400, parity bit to 1, Modbus address 3

these parameters can be changed through Modbus using the write function

10.

Once the configuration is done, write data 1 at address Dec. 40565. After

changing the parameters the product buzzer will sound twice and the Com

LED will stay on.

To reset to default parameters press the

button for 30 seconds, the

product will reboot and the standard communication settings will be set.

Technical characteristics

Denomination

Terminal Description

Characteristics

Recommended Cable

section

Tightening torque / screw

type

Control signal outputs (orders

to RTSE)

14

Position II order

AC1 - General use - Ie : 5A, Ue : 250 VAC

DC1 - General use - Ie : 5A, Ue : 30 VDC

1 … 2.5mm²

0.58 Nm

15

Position I order

16

Position 0 order

17

Common point for position output

RS485*

35

NC - Not connected

RS485 isolated bus

LiYCY shielded twisted pair

0.2 Nm / M2

36

Negative electrode

37

Positive electrode

Output for genset

51

Common point

1 … 2.5mm²

0.58 Nm

52

Normaly closed contact

AC1 - General use - Ie : 3A, Ue : 250 VAC

DC1 - General use - Ie : 3A, Ue : 30 VDC

54

Normaly open contact

AC1 - General use - Ie : 5A, Ue : 250 VAC

DC1 - General use - Ie : 5A, Ue : 30 VDC

Controller inhibit input

63A

Controller is inhibited when this contact

is open

Do not use external voltage - Power from

common point

0.5 … 1.5mm²

0.2 Nm / M2

64A

Position inputs (return of

information from RTSE)

70

Common point for position inputs

Do not use external voltage - Power from

common point

0.5 … 1.5mm²

0.2 Nm / M2

71

Position I RTSE

72

Position II RTSE

73

Position 0 RTSE

Fire input

F1

Negative electrode of the 24 VDC

12-24 VDC

0.5 … 1.5mm²

0.2 Nm / M2

F2

Positive electrode of the 24 VDC

Optional Auxiliary supply

24 VDC

81

Negative electrode of the 24 VDC

10-30 VDC (Auxiliary supply for controller,

does not supply RTSE)

1 … 2.5mm²

0.58 Nm / M3

82

Positive electrode of the 24 VDC

Source 1 and 2 voltage inputs

103

Source 1 N

Sensing range:

50-300 VAC L/N

90-520 VAC L/L’

Range:

184-300 VAC L/N

Max consumption: 10 W

1 … 2.5mm²

0.58 Nm / M3

104

Source 1 L1

105

Source 1 L2

106

Source 1 L3

203

Source 2 N

204

Source 2 L1

205

Source 2 L2

206

Source 2 L3

DPS output (RTSE power

supply)

301

Phase output

AC - General use - Ie : 6A, Ue : 250 VAC

DC - General use - Ie : 6A, Ue : 30 VDC

1 … 2.5mm²

0.58 Nm / M3

302

Neutral output

* for HZI825 only