1

6LE000377A

TYB6.2F

Output 2gang 6A / 1gang shutter/blind,

flush mounted

Input 2gang + output 2gang 6A / 1gang

shutter/blind, flush mounted

TXB6.2F

Output 2gang 6A / 1gang shutter/blind,

flush mounted

Input 2gang + output 2gang 6A / 1gang

shutter/blind, flush mounted

z

07/2014 - 6LE000377A

Hager Controls S.A.S., 33 rue Saint-Nicolas, B.P. 10140, 67703 SAVERNE CEDEX, France - www.hager.com

Bn,.:

M

`

Safety instructions

Electrical equipment may only be installed and

assembled by a qualified electrician in accor-

dance with the relevant installation standards,

guidelines, regulations, directives, safety and

accident prevention regulations of the country.

Failure to comply with these installation in-

structions may result in damage to the device,

fire or other hazards.

Hazard due to electric shock. Disconnect be-

fore working on the device or load. Take into

account all circuit breakers that supply

dangerous voltages to the device or load.

Hazard due to electric shock. The device is not

suited for safe disconnection of the mains sup-

ply.

Hazard due to electric shock on the SELV or

PELV installation. Do not connect any loads for

low voltage SELV, PELV or FELV together.

Connect one motor only. If several motors are

connected, motors or device might be destro-

yed.

Use drives with mechanical or electrical final

position switches only. Check final position

switches for correct adjustment. Observe

motor manufacturer‘s data. The device can be

damaged.

Observe the motor manufacturer‘s data

regarding change-over time and max. switch-

on time (ED).

These instructions are an integral component

of the product and must be retained by the end

user.

Design and layout of the device

S1 S2

KNX+ /RD

KNX- /BK

In 1 /GN

Com /WH

In 2 /YE

(1)

(2)

(3)

Fig. 1: example device variant with inputs

(1) Illuminated button for manual operation/

programming button

(2) Connection of load(s)

(3) KNX bus connection cable/

connection inputs

Function

System information

This device is a product of KNX system and corre-

sponds to the KNX guidelines. Detailed specialised

knowledge obtained from KNX training courses is

required for understanding. The planning, installa-

tion and commissioning of the device is carried out

with the help of KNX-certified software.

Systemlink commissioning

The function of the device is software-dependent.

The software is to be taken from the product

database. You can find the latest version of the

product database, technical descriptions as well as

conversion and additional support programmes on

our website.

Easylink commissioning

The function of the device is configuration-depen-

dent. The configuration can also be done using

devices developed specially for simple setting and

start-up.

This type of configuration is only possible with

devices of the easylink system. Easylink stands for

easy, visually supported start-up. Preconfigured

standard functions are assigned to the in/outputs

by means of a service module.

Functional description

The device receives telegrams from sensors or

other controllers via the KNX installation bus and

switches electrical loads with its relay contact.

Correct use

- Switching of electrical loads AC 230 V with po-

tential-free contact.

- Switching electrically operated motors of 230 V

AC for blinds, shutters, awnings and similar

hangings.

- Installation into wall box according to DIN

49073 (use deep box) or junction box surface-

mounted/flush-mounted.

Product characteristics

- Manual activation of the outputs on the device

possible, building site operation.

- Status display of the outputs on the device.

- Scene function.

- Forced position by higher-level controller.

Functions in switch operation

- Time switching functions.

Functions in roller shutter/blind operation

- Position can be started directly.

- Slat position directly controllable.

- Feedback of operating state, shutter position

and slat adjustment.

- 3 Alarms.

Functions of the inputs

- ON/OFF.

- Dimming.

- Up/down.

- Slat angle/Stop.

- Alarm.

- Scene.

- Mandatory control.

- Time switching operation.

Information for electricians

Installation and electrical connection

DANGER!

Touching live parts can result in an

electric shock!

An electric shock can be lethal!

Disconnect the connecting cables

before working on the device and

cover all live parts in the area!

ç

Connecting and installing the device

CAUTION!

Impermissible heating if the load of

the device is too high!

The device and the connected cables

may get damaged in the connection

area!

Do not exceed the maximum current

carrying capacity!

ç

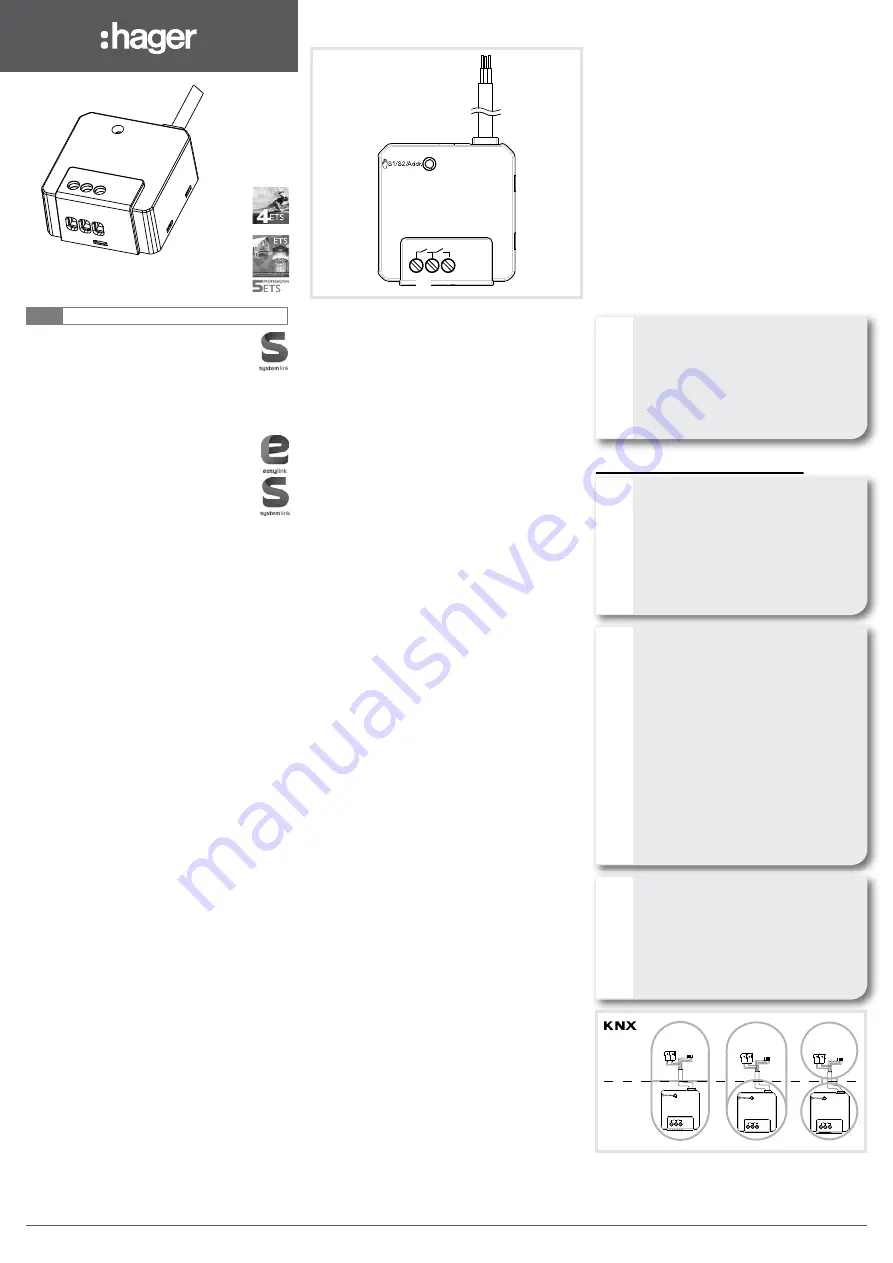

CAUTION!

When connecting the bus/extension

units and mains voltage wires in a

common wall box, the KNX bus cable

might come into contact with the

mains voltage.

The safety of the entire KNX

installation is at risk. Persons could

also get an electric shock even on

remote devices.

Do not place bus/extension units and

mains voltage terminals in a common

terminal compartment. Use a wall box

with a firm partition or separate boxes

(Figure 2).

ç

CAUTION!

Risk of destruction if parallel circuit of

several motors!

Final position switches could fuse

together. Motors, hangings and the

device may be destroyed!

Connect one motor only!

ç

S1 S2

KNX+ /RD

KNX- /BK

In 1 /GN

Com /WH

In 2 /YE

S1 S2

KNX+ /RD

KNX- /BK

In 1 /GN

Com /WH

In 2 /YE

S1 S2

KNX+ /RD

KNX- /BK

In 1 /GN

Com /WH

In 2 /YE

SELV

FELV

230 V AC

Figure 2: installation with separate terminal com-

partment

S1 S2

KNX+ /RD

KNX- /BK

In 1 /GN

Com /WH

In 2 /YE

Bus

30 V DC

L

N

10 A

In 1

In 2

Com

Figure 3: connection of switching loads

S1 S2

KNX+ /RD

KNX- /BK

In 1 /GN

Com /WH

In 2 /YE

Bus

30 V DC

L

N

10 A

In 1

In 2

Com

Figure 4: connection of motors

Observe installation regulations for SELV voltage.

Maintain a minimum distance of 4 mm between

mains voltage and bus wires.

The installation circuit must be protected via circuit

breaker 10 A.

Do not connect different phases (outer conductors)

to the device.

z

Connect bus cable via connecting terminal.

z

Connect loads (figure 3/4) to the load connec-

ting terminals (2).

z

Place device into the installation box.

Connect inputs

green

white

yellow

red

black

In 1

Com

In 2

KNX+

KNX-

Table 1: connection assignment of the control line

z

Connect potential-free contacts to the inputs.

Start-up

Systemlink: loading physical address and

application software

z

Switch on bus voltage.

z

Press programming button (1).

The button lights up.

If the button does not light up, no bus voltage is

present.

z

Load the physical address into the device.

Status LED of the button goes out.

z

Load application software.

z

Note down the physical address on the device.

Easylink

Information on the system configuration can be

taken from the extensive description of the service

module Easylink.

Start up the device

z

Switch on mains voltage on the outputs.

Switch test mode on/off

The device is connected. Bus voltage and swit-

ching voltage are present.

z

Keep button (1) pressed > 5 s with a pointed

object until it flashes green.

The device is in test mode.

Or with test mode switched on

z

Keep button (1) pressed > 5 s until it flashes

green 3 times.

The device is in normal operation.

After approx. 5 min. without any further operati-

on, the device exits test mode automatically.

Operating output in test mode

Operation takes place by briefly pressing a button

repeatedly (1).

The device is in test mode. The button flashes

green until the first operation.

z

Press the button (1) for a short time.

The output changes its switching state.

The switching takes place according to the

following sequence:

S1 closed - S1 open - S2 closed - S2 open.

Resetting the device to the factory settings

z

The device provides the possibility of restoring

the factory setting via a programming button.

The programming is lost after resetting to the

factory setting. Activation via the bus is no

longer possible.

z

Hold down the button (1) for (> 10 s) until it

flashes red.

P

P

P

P

Appendix

Technical data

Supply voltage KNX

21…32 V DC SELV

Breaking capacity

µ 6 A AC1 230 V~

Switching current at cos Φ = 0.8

max. 6 A

Minimum switching current

10 mA

Operating altitude

max. 2000 m

Degree of contamination

2

Surge voltage

4 kV

Degree of protection of housing

IP20

Impact protection

IK 04

Overvoltage class

III

Operating temperature

-5°C…+45°C

Storage/transport temperature

-20°C … +70°C

Maximum switching cycle rate

at full load

20 switching cycle/minute

Connection capacity

0.75 mm²…2.5 mm²

max. tightening torque

0.5 Nm

Cross-head design

PZ1

Installation type flush-mounted installation switch/

flush-mounted electronic/

flush-mounted/surface-mounted junction box

Standards

EN 50491-3 ; EN 60669-2-1

Dimensions

44 x 43 x 22.5 mm

Own consumption on the KNX bus:

typical

7 mA

in standby

5 mA

Incandescent lamps

500 W

HV halogen lamps

500 W

Conventional transformer

500 VA

Electronic transformer

500 W

Fluorescent lamps

- without ballast

500 W

- with electronic ballast

6 x 48 W

Energy-saving lamps

5 x 13 W

LED lamps

5 x 13 W

Change-over time for

change of direction

software-dependent

Variant with inputs

Number of inputs

2

Input type

potential-free

Total length of extension unit cable

max. 9.9 m

Scanning voltage

extension unit inputs

12 V DC/1mA

Troubleshooting

Test mode not possible. Red programming LED

lights up.

Cause: push-button (1) was pressed too short.

Short press on push-button, red LED goes out.

Press push-button again (> 5 s).

Bus operation is not possible

Cause 1: bus voltage is not present.

Check bus connection terminal for correct

polarity.

Check bus voltage by briefly pressing the pro-

gramming button (1), red LED lights up if bus

voltage is present.

Cause 2: device was reset to the factory setting.

Repeat programming and start-up.

z

z

230 V

v

230 V

v

z

6LE000377C

1

6LE000377C

v