7

Installation and Maintenance Manual, Compact CBP

Maintenance

4.3

Commissioning

- During initial starting and the period im-

mediately after it, any hydraulic installa-

tion must be regularly and carefully checked at

frequent intervals.

- The working pressure and charge pressure must

be checked to ensure that they correspond to

the contracted values.

- The pressure in the drain line measured at the

motor must be less than bar (4,5 psi). This

pressure limit is important for the life of the

motor seals.

- If leakage occurs, correct the fault and carry out

new measurements.

- Check all lines, connections, screws, etc. and

correct if necessary.

- Check other possible leakage points and re-

place faulty parts.

- During the start up period, dirt particles in the

system are removed by the filters. The filter

cartridges have to be changed after the first

100 working hours and after that according to

the maintenance chart. see 4.4 note to check

the "filter clogged" indicators.

NOTE:

-

When starting up the motor it is important

that the motor output power is limited to max

power according to these technical data.

A not run-in motor in combination with dirt partic-

les in the oil can badly affect the sliding surfaces

in the motor. This is valid during the first 100

working hours.

4.2

Before commissioning

Place the motor as shown in fig 4.1, fill the motor

with filtered oil in the following order: D1, A1, B, C1.

See ., "Filtration".

Take extreme care to ensure that no contamination

enters the motor.

Seal connections A and C with the cover plate

fitted to the connection surface at delivery. Check

that the O-rings or rubber seals are in postion in

the cover plate.

Fit the plug to D1, D and D, the table below states

the amount of oil needed to fill the various types

of motors.

Check the following points before commissioning

the motor, i.e. before starting the first time:

- Check that the motor is connected to give

the correct direction of rotation (see . "Oil

connections" and ..1 "Direction of rotation of

motor shaft").

- Select the hydraulic fluid in accordance with the

recommendations (see . "Choice of hydraulic

fluid").

- Fill the motor housing with hydraulic fluid via a

filter into the drain outlets D1, D or the vent hole

(depending on how the motor is mounted).

- Check the drain line to ensure that excessive

pressure does not build up in the motor housing;

see .1 "Mounting instructions" and ...

"Draining and venting the motor".

- Check that the motor is protected from overloads

(see 1.1 "Motor data").- Check that the charge

pressure conforms to the charge pressure curve

(see .1 "Recommended charge pressure").

- Check that all hydraulic couplings and plugs are

properly tightened to prevent leakage.

- Make sure that the torque arm is sufficiently

fastened, see .1..

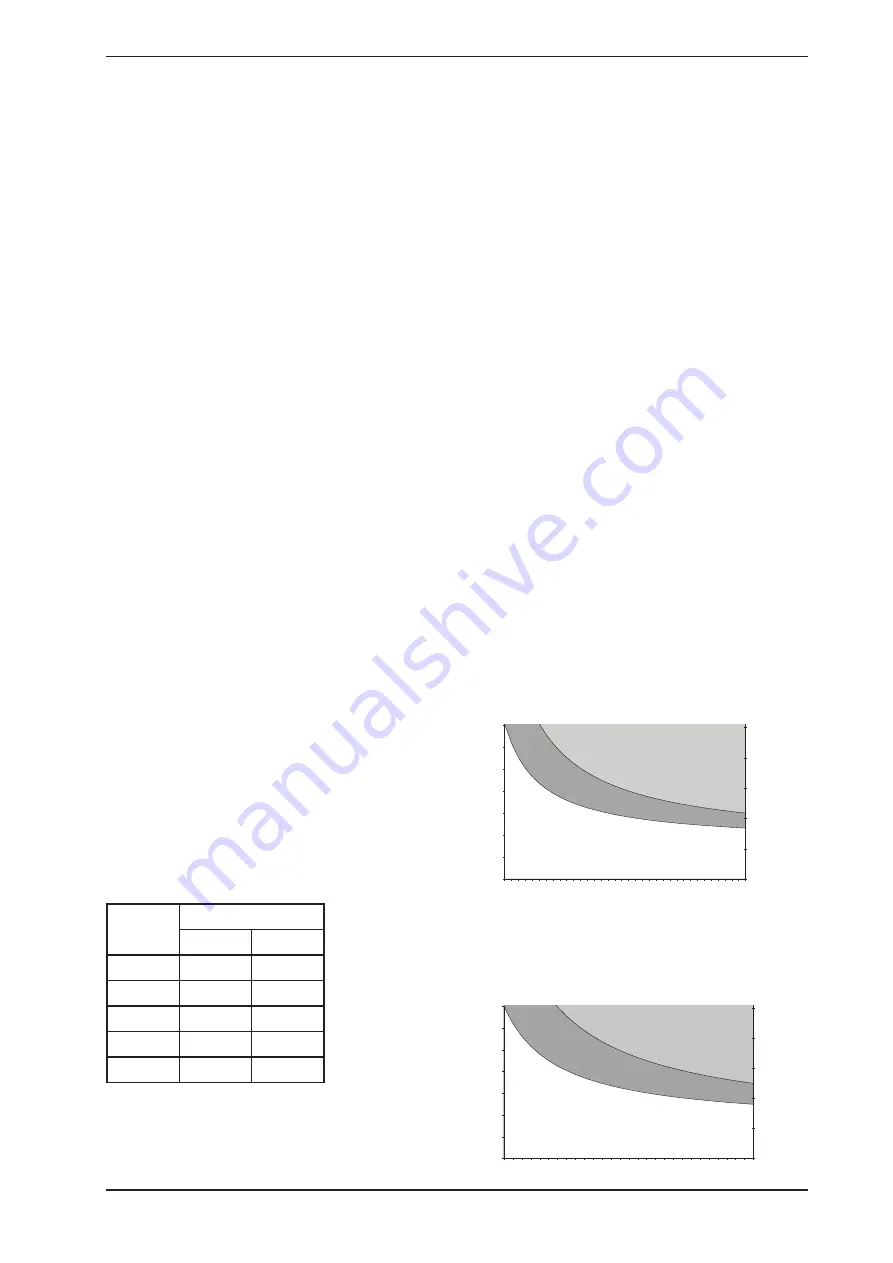

Table 4.1

Motor

Oil volume approx.

Litres

US gal.

CBP 140

5,0

1,

CBP 80

9,0

7,6

CBP 400

5,0

9,

CBP 560

5,0

9,

CBP 840

41,0

10,8

CBP 140

0

50

100

150

200

250

300

350

50

70

90

110 130 150 170 190 210 230 250 270 290 310 330 350 370 390

Speed [rpm]

H

ig

h

pr

es

su

re

[b

ar

]

0

1000

2000

3000

4000

5000

H

ig

h

pr

es

su

re

[p

si

]

0

50

100

150

200

250

300

350

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

Speed [rpm]

H

ig

h

pr

es

su

re

[b

ar

]

0

1000

2000

3000

4000

5000

H

ig

h

pr

es

su

re

[p

si

]

CBP 80-840

10 cSt

20 cSt

5 cSt

10 cSt

20 cSt

5 cSt