x

VII.

SERVICE AND MAINTENANCE

LUBRICATION

Leg Bearings

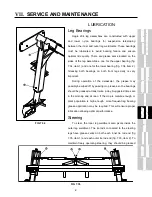

Hagie 204 leg assemblies are constructed with upper

and lower nylon bearings for suspension telescoping

between the inner and outer leg weldments. These bearings

must be lubricated to avoid bearing failure and ensure

optimal ride quality. There are grease zerks located on the

sides of the leg assemblies, one for the upper bearing (fig.

7.34, item 1) and one for the lower bearing (fig. 7.34, item 2).

Greasing both bearings on both front legs daily is very

important.

During operation of the detasseler, the grease may

possibly be wiped off by passing crop leaves, so the bearings

should be greased at least twice a day. Suggested times are

in the morning and at noon. If the crop is mature enough, or

plant population is high enough, more frequent leg bearing

grease application may be required. This will ensure proper

lubrication allowing optimal performance.

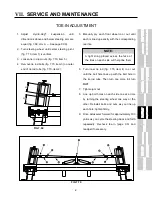

Steering

To steer, the inner leg weldment also pivots inside the

outer leg weldment. The tie rods connected to the steering

legs have grease zerks on both each inner tie rod end (fig

7.35, item 1) and each outer tie rod end (fig. 7.35, item 2). To

maintain freely operating steering, they should be greased

FIG 7.35

1

2

1

2

FIG 7.34

1

2

Summary of Contents for 204

Page 133: ...x IX TROUBLE SHOOTING TASSELTROL LS SYSTEM ELECTRICAL CONTINUED FIG 9 1 1 2...

Page 134: ...x IX TROUBLE SHOOTING NOTES...

Page 140: ...138 NOTES...

Page 141: ...x...