IV.

OPERATING SYSTEMS

39

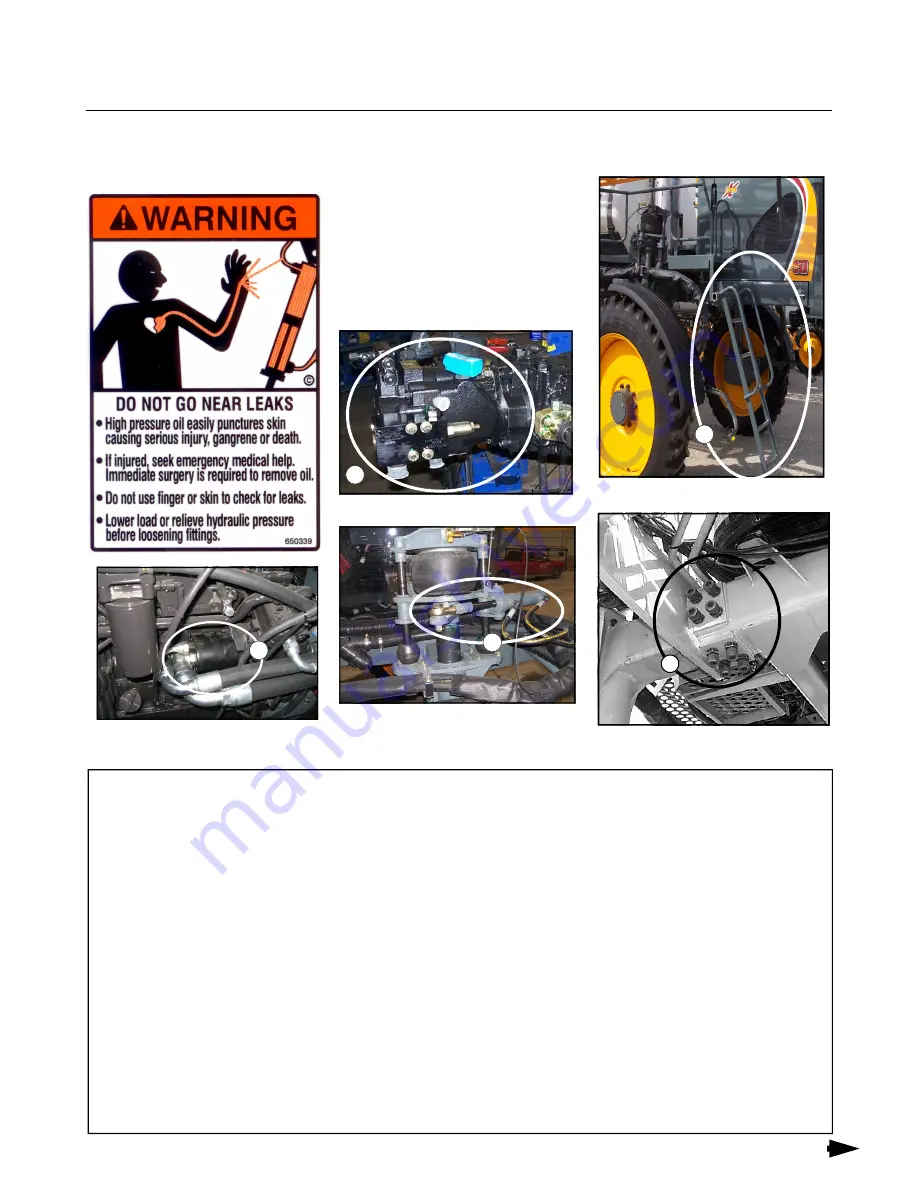

C. HYDRAULIC SYSTEM

A. Hydraulic Pump

B. Power Steering

C. Ladder

D. Tread Adjust

E. Gear Pump

The

AUXILIARY HYDRAULIC SYSTEM

is a load sensing, pressure compensated system with effi-

ciency in mind. That means it only pumps the amount of oil needed to do the job.

The pump is mounted to the “front” of the second hydrostatic pump (fig. 39-2).The systems consist of a

single variable displacement pump that supplies the required hydraulics to operate the full time power steering

unit, boom control cylinders (lift, level, and fold), tread adjust, ladder, outer boom breakaway, and the solution

pump.

The return oil from the load sense pump is mixed with the oil from the gear pump (fig. 39-1) on the side of

the engine. This pump supplies a constant flow of oil from the hydraulic tank to the cooler and then back to the

tank through the filter. This is considered a kidney loop and is dedicated to the cooling and filtration of the hy-

draulic system.

For detasseling operation, there is an additional valve to include the gear pump flow into the system to

supplement hydraulic flow for operation of three or more lift sections.

FIG. 39-3

FIG. 39-4

C

B

FIG. 39-2

FIG. 39-5

D

A

BASIC MACHINE

OPERATING SYSTEMS

FIG. 39-1

E