7-38

SECTION 7 –

SPRAY SYSTEMS

Visit

www.teejet.com

for further

information.

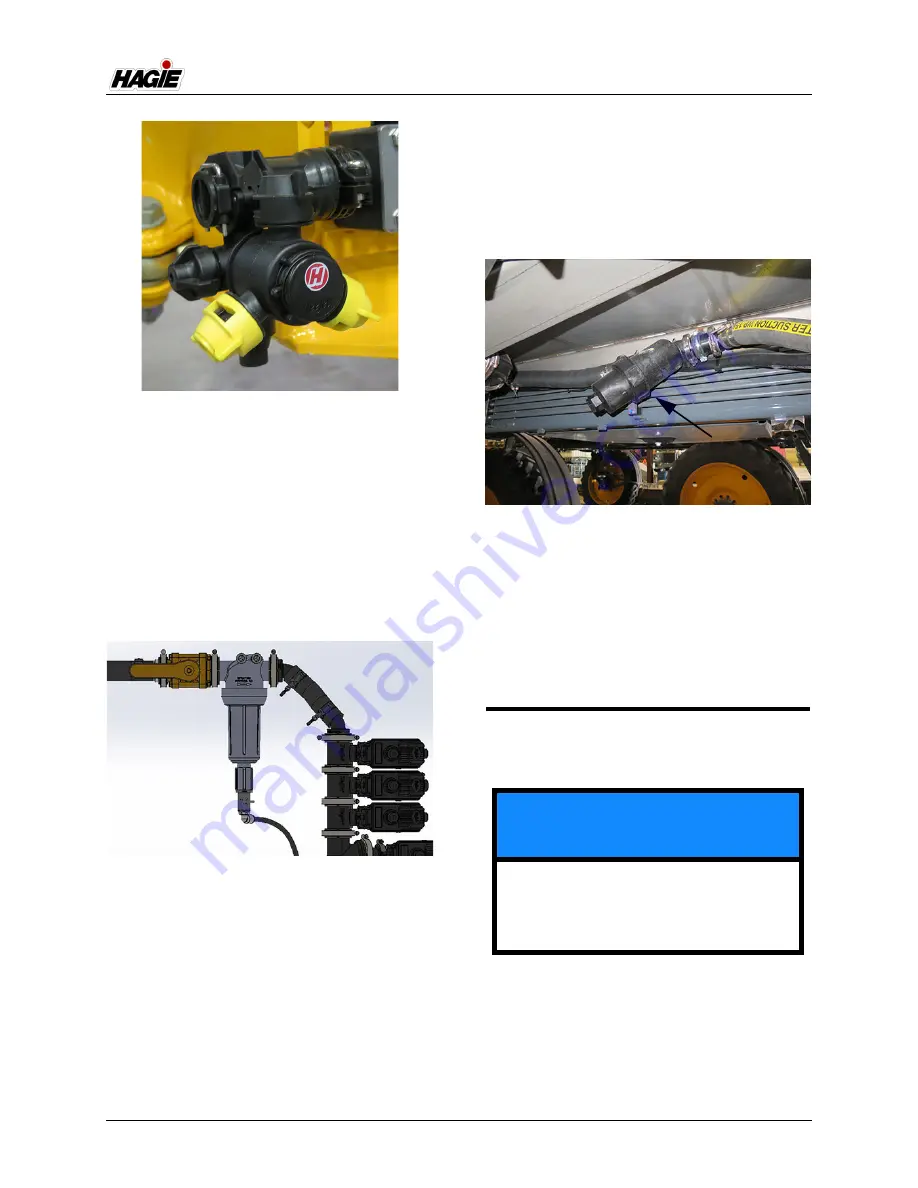

Section Strainers

(80-Mesh Strainer Screens)

Two (2) Section Strainers are located on

the transom and filter impurities to aid in the

avoidance of spray nozzle buildup.

Refer to “Service - Filters” provided in the

Maintenance and Storage Section

elsewhere

in this manual for maintenance information.

Solution Line Strainer

(50-Mesh Strainer Screen)

A Solution Line Strainer is located

beneath the center right-hand side of

machine and is the main strainer to filter

solution system impurities and maintain

consistent application rates.

Refer to “Service - Filters” provided in the

Maintenance and Storage Section

elsewhere

in this manual for maintenance information.

SOLUTION SYSTEM -

OPERATION

Nozzle Body

(Located throughout boom)

-Typical View

Section Strainer (2)

(Located on transom)

-Typical View

NOTICE

The Solution System has been tested

using RV-type antifreeze. Fill solution

tank with fresh water and drain before

initial use.

Solution Line Strainer

(Located beneath the center

right-hand side of machine)

-Typical View

Summary of Contents for STS/DPS Series

Page 2: ...5 DASH AUTO...

Page 5: ...Troubleshooting 10 38...

Page 52: ...SECTION 2 SAFETY AND PRECAUTIONS 2 15 650210 Located on each NORAC sensor...

Page 380: ...NOTES 5 DASH AUTO...

Page 381: ...NOTES 5 DASH AUTO...

Page 382: ...NOTES 5 DASH AUTO...