VII.

SERVICE AND MAINTENANCE

G. BOLT TORQUE

127

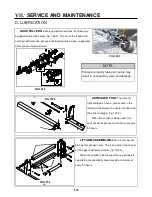

WHEEL BOLTS–

If you do not have the proper equipment to mount a

tire, let your local qualified tire sales/service dealer mount the tire for you. The

tire should be mounted on the rim according to figure 127-1 for best traction

and tread cleaning action. To install wheel and tire assembly on the wheel

hub lubricate studs with an anti-seize grease. Align the wheel bolt holes with

the wheel hub studs and mount the wheel on the hub.

Start all of the lug nuts and tighten them until they are just snug. Following the torque sequence in figure

127-3, first turn each lug nut to a torque value of 120 dry foot– pounds. Use slow, even pressure on the torque

wrench. Quick or jerky movements cause inaccurate values. Repeat the same sequences to 150 dry foot–

pounds and again finally to 400 to 500 dry foot– pounds.

If the wheel turns during lug nut torquing, lower the machine to

the ground just enough for the tire to touch and prevent rotation or

more preferably, place a suitable wedge between the tire and the

ground.

Lower the machine and resume operation. Recheck torque after

30 minutes of operation.

FIG 127-3

10

9

8

7

6

5

4

3

2

1

Check lug nut torque immediately after receiving

machine and every 50 hours thereafter.

FIG 127-1

FIG 127-2

NOTE:

To achieve even torquing consistency, the tire should be

completely off the ground.