VII.

SERVICE AND MAINTENANCE

H. TOE– IN

129

GAUGING TOE-IN–

To correctly gauge toe-in, phase the cylinders first (page 41).Then use a tape

measure placed at one-half the height on the front center seam of the front tire compared to the same meas-

urement of the rear of the front tire (subtract the front measurement from the rear measurement— it must be a

positive number). Correct toe-in should fall between one half and three quarters of an inch.

Toe-in is preset at the factory and should not have to be adjusted unless the steering cylinders are re-

moved.

Difficulty steering one way versus the other or “darting” during operation, may indicate incorrect toe-in and

may require adjustment.

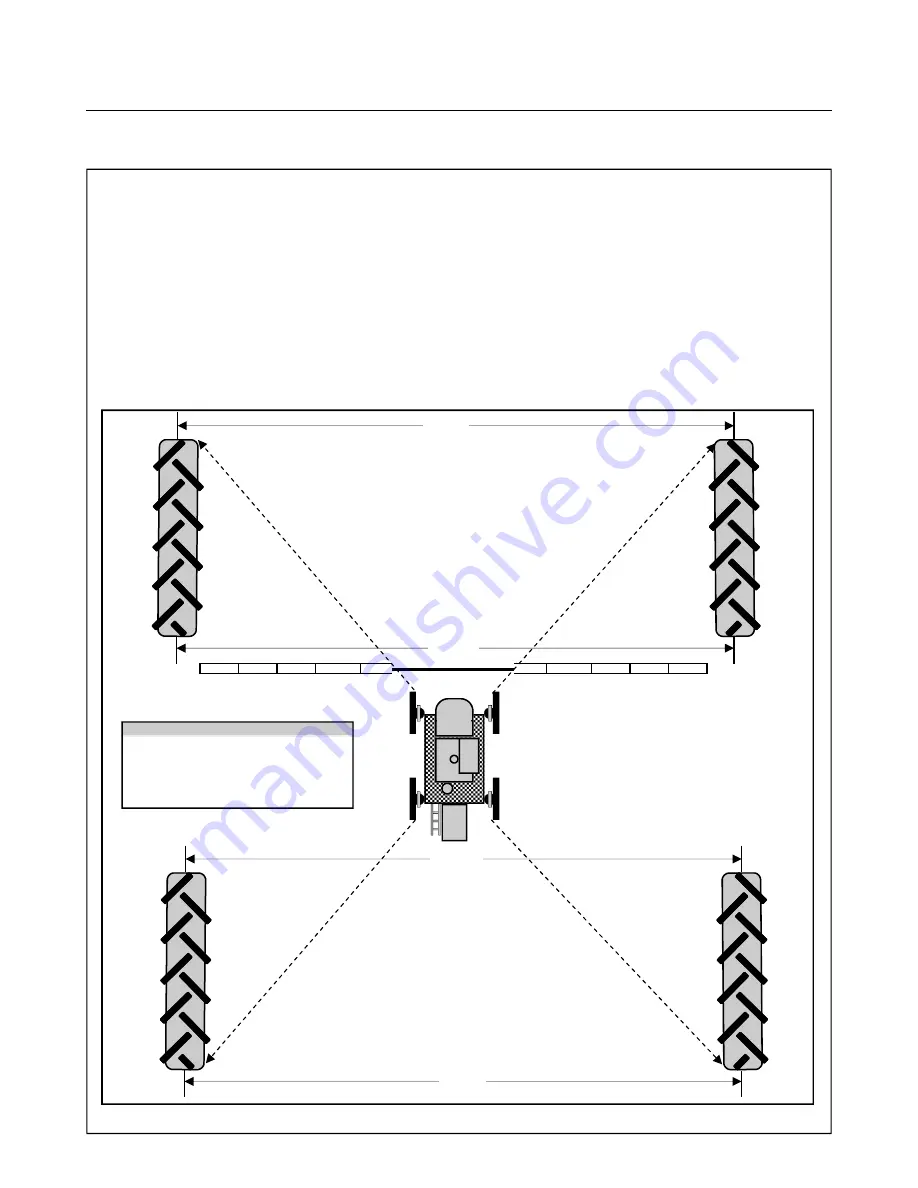

EXAMPLE OF CORRECT TOE-IN FOR A

MACHINE WITH 120 INCH TREAD WIDTH.

(MUST HAVE ½" TO ¾" TOE-IN.)

119¾”

120¼”

NOTE:

See next page for instructions on adjusting

toe-in. See also page 41 for information on

recalibrating self-centering cylinders.

EXAMPLE OF CORRECT REAR TOE-IN FOR A

MACHINE WITH 120 INCH TREAD WIDTH.

(MUST BE STRAIGHT.)

120”

120”

FIG 129-1