9-33

SECTION 9 –

MAINTENANCE AND STORAGE

From the collection tank, air is sent to the

Air Bags as needed to maintain a level

pressure. Control valves open and close to

allow air in.

•

Inspect the Air Dryer cartridge every 50

hours of operation to ensure that it is

purging with compressor load. Change

the cartridge every 1,000 hours of opera-

tion, or as needed.

•

Inspect Air Bags daily for leaks and/or

cracking. If an Air Bag is low, check the

bag for any punctures or leaks.

Contact your local John Deere dealer if

assistance is needed.

Air Tanks

Your machine may be equipped with two

Air Tanks. The

Main Air Tank - standard

(located beneath platform on the left-hand

side of machine) provides a volume of

compressed air to give faster response for

changes in air volume to the air bags.

The

Air Purge Tank - if equipped

(located beneath platform near center of

machine) is used to push solution out of the

boom line, reducing the amount of rinse

water needed to clean the solution system of

chemical.

•

Drain each Air Tank daily by slowly

releasing the Tank Drain Valve.

NOTE: Check for moisture. If excessive

moisture is in the tank(s), there may

be a system malfunction. Contact

your local John Deere dealer if

assistance is needed.

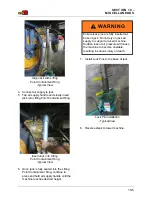

Tank Drain Valve (Main)

(Located beneath platform

on left-hand side of machine)

* Pull DOWN to open

-Typical View

Tank Drain Valve (Air Purge) -

if equipped

(Located beneath platform

near center of machine)

* Pull DOWN to open

-Typical View