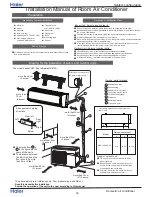

Detach the service port’s cap of

1.

3-way valve, and the valve cap for 2-way valve

and 3-way valve. Connect the service port to the low side of the gauge manifold

Open the handle on the low side of the gauge manifold and operate vacuum pump.

2.

Vacuum the tubing for at least 15 minutes. The vacuum level on the low side gauge

should be 29.9 in of Hg, 76 cm of Hg, 0.1 MPa. when vacuuming is complete, close

the valve on the manifold and turn off the vacuum pump. The vacuum level should

hold for 1-2 minutes. If the vacuum level does not hold, check the flared connections

and repeat this step.

3.

Purging Method:To use vacuum pump

5

Open

Open the 2-way valve 1/4 turn. After 5-6 seconds, close the valve and inspect for

leaks with a leak detector or soap solution.

4.

No gas leakage? Go to step 6.

5.

Detach the charge hose

6.

from the service port, open 2-way valve and 3-way

Gauge manifold

Gaugemanifold(for R410A)

2-way valve Liquid Side

3-way valve Gas Side

Vacuum pump

Tube(for R410A)

Close

2-way valve

3-way valve

Open 90

O

2-way valve

3-way valve

2-way valve 3-way valve

2-way valve

3-way valve

Valve cap

Valve cap

Service port cap

After attaching the caps, check for leakage around the caps.

7.

8.

Step 1.

Step 2.

Step 3.

Step 7.

Step 6.

Step 4.

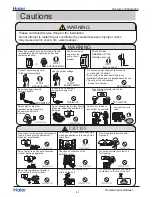

The power source must be exclusively used for air

●

conditioner.

In the case of installing an air conditioner in a moist place,

●

please install an ea-

For installation in other places, use an HVACR circuit breaker of time delay fuse.

●

If the refrigerant of the air conditioner leaks, it is necessary to discharge all the

●

according to the amount marked on the name plate.

Please do not let other cooling medium, except speci

fi

ed one (R410A), or air

●

enter into the cooling circulation system. This could cause high pressure and

1

Power Source Installation

CAUTION

rth leakage breaker.(GFCI)

2

On Drainage

It becomes

high midway.

The gap with the

ground is too small.

There is the bad

smell from a ditch

It waves.

The end is imm-

ersed in water.

Please install the drain hose and ensure downward flow.

Please don’t do the drainage as shown below.

●

●

Please pour water in the drain pan of the indoor unit, and

●

is proper.

In case that the attached drain hose is in a room, please

●

apply insulation to

Less than

5cm

con

fi

rm that drainage

to the hose to prevent condensation.

Check Items for Test Run

Please kindly explain to our customers how to operate

through the instruction manual.

Check for Installation and Test Run

■

■

1

1+2=

kg

R410A

2

kg

2=

1=

B

C

D

F

E

kg

A

This product contains fluorinated greenhouse gases covered by

the Kyoto Protocol. Do not vent into the atmosphere.

Refrigerant type:R410A

GWP* value:1975

GWP=global warming potential

Please fill in with indelible ink,

• 1 the factory refrigerant charge of the product

• 2 the additional refrigerant amount charged in the field

and

• 1+2 the total refrigerant charge

on the refrigerant charge label supplied with the product.

The filled out label must be adhered in the proximity of the product

charging port (e.g. onto the inside of the stop value cover).

A contains fluorinated greenhouse gases covered by the Kyoto

Protocol

B factory refrigerant charge of the product: see unit name plate

C additional refrigerant amount charged in the field

D total refrigerant charge

E outdoor unit

F refrigerant cylinder and manifold for charging

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol

Refrigerant charge label

■

Put check mark

in boxes

To prevent the gas leakage,

continues, remove the refrigerant used for the leakage check and flare

tubes again. Repeat vacuum and leak and if no leakage, proceed to step 6.

replace the service port and valve caps.

Gas leak from interconnecting tubing?

Installation is on the interconnecting tubing?

Are the connecting wirings of indoor and outdoor

fi

rmly

Is the connecting wiring of indoor and outdoor

fi

rmly

fi

xed?

Is drainage securely carried out?

Is the ground wire securely connected?

Is the indoor unit securely

fi

xed?

Is power source voltage the local codes?

Is there any noise?

Are the lights near the unit working normally?

Are cooling and heating (when in heat pump) performing normally?

Is the operation of room temperature control normal?

inserted to the terminal block?

Loosen the screws on

●

terminal block and insert the wires fully into terminal

block, then tighten the screws.

If wiring is not correct, the unit will not operate properly and it could cause a

●

Fix the cable with a clamp.

●

Connection

3

If the drain-elbow is used,

●

please attach as shown in figure.

(Note: Only for heat pump unit.)

Attaching Drain-Elbow

4

defect in the unit.

and connect the vacuum pump to the center port of the manifold.

In case of a leak, try tightening the flare connections to fix the leak. If the

leak stops, go to step 6. If the leak continues, check the flare connections

and repair as needed, then go back to step 3. then proceed step 6. If leak

valve completely.

refrigerant. Repair the leak, vacuum the unit then charge the liquid refrigerant

into air conditioner

could cause a leak and lead to personal injuries.

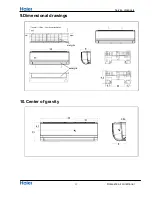

System configuration

Domestic air conditioner

39