INSTALLATION

PAGE 38

ENGLISH

SE

C

TION A

9

Louver SWING Button - Vertical

Air Flow Direction Adjustment

Press the SWING UP/DOWN button to choose the position of

the vertical airflow louvers.

Status display of air flow

COOL/DRY:

HEAT:

Caution:

•

It is advisable not to keep the vertical louver in the down-

ward position for an extended period of time in COOL or

DRY mode, otherwise condensate water may form on the

louver.

•

Note:

When turning the unit on, the remote control will automatically

return the louver to the previous set swing position. When turn-

ing the unit off, the louver will rotate to the full open position

prior to closing

.

10

Louver SWING Button - Horizontal

Press the SWING UP/DOWN button to choose the position of

the horizontal airflow louvers.

Status display of air flow

COOL/DRY/HEAT:

'

Caution:

•

When humidity levels are high, condensate water may oc-

cur at the air outlet if all horizontal louvers are adjusted to

left or right.

Note:

When turning the unit on, the remote control will automatically

return the louver to the previous set swing position. When turn-

ing the unit off, the louver will rotate to the full open position

prior to closing

.

11

Timer ON Button

On-Off Operation

1. Start the unit and select the desired operating mode.

2. Press the TIMER ON

button to enter the TIMER ON

mode. The remote control will start flashing “ON”.

3. Every time the TIMER ON button is pressed the length of

time increases in 0.5 hour increments between hours 0 and

12, and 1 hour increments for times between hours 12 and

24.

4. Once the desired length of time is selected for the unit to

turn on, press the CONFIRM/CANCEL

to confirm

this setting.

The remote control display changes as follows:

BLANK

TIMER ON TIMER OFF

TIMER ON-OFF

TIMER OFF-ON

0.5h

0.5h

0.5h

0.5h

Cancel TIMER ON setting:

With a TIMER ON set, press the CONFIRM/CANCEL

button once to cancel the TIMER ON.

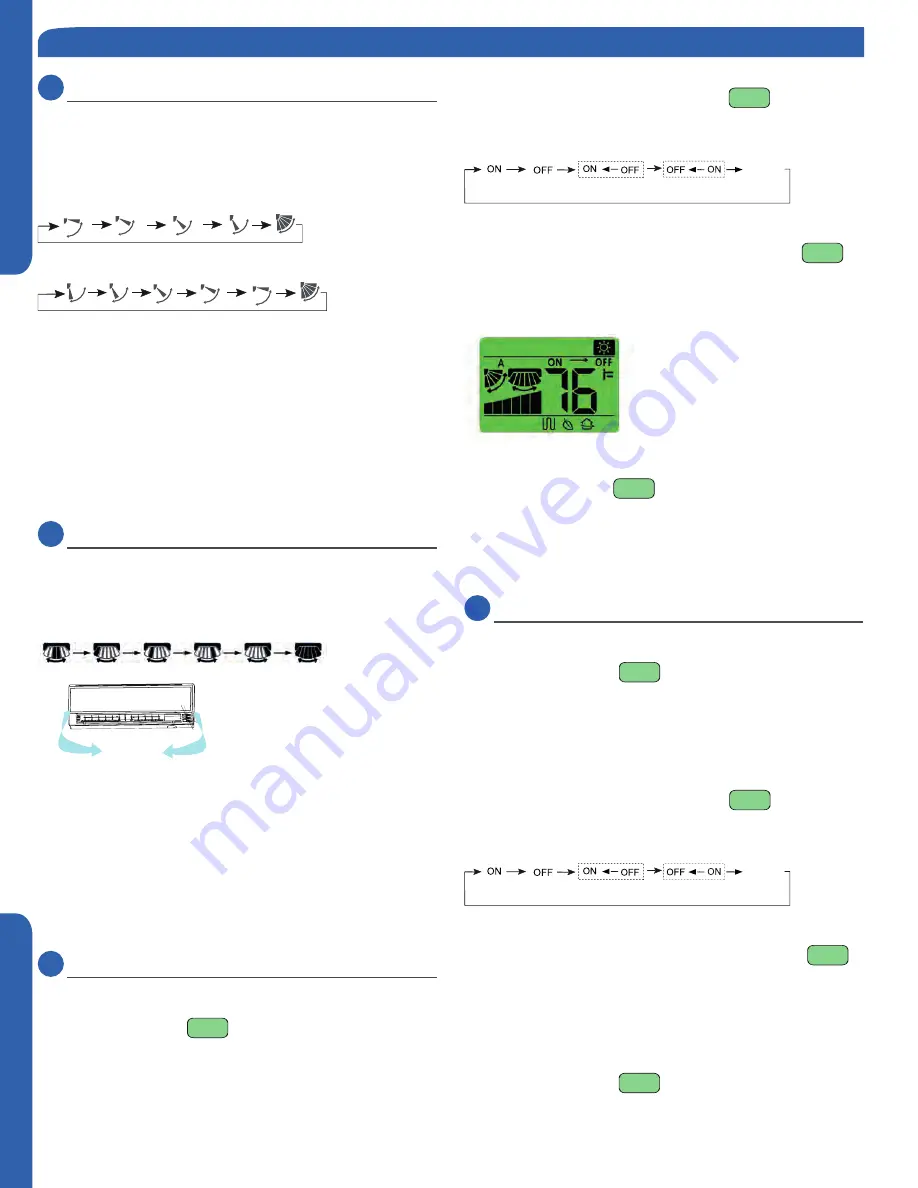

Turning the unit ON with the TIMER from it being OFF will look

like this on the remote control display:

Note:

Holding the TIMER ON

button down will rapidly cycle

the time. After replacing batteries or a power failure occurs,

the time setting will need to be reset.

According to the Time setting sequence of TIMER ON or

TIMER OFF, either Start-Stop or Stop-Start can be achieved.

12

Timer OFF Button

On-Off Operation

1. Start the unit and select the desired operating mode.

2. Press the TIMER OFF

button to enter the TIMER OFF

mode. The remote control will start flashing “OFF”.

3. Every time the TIMER OFF button is pressed the length of

time decreases in 0.5 hour increments between hours 0

and 12, and 1 hour increments for times between hours 12

and 24.

4. Once the desired length of time is selected for the unit to

turn off, press the CONFIRM/CANCEL

to confirm

this setting.

The remote control display changes as follows:

BLANK

TIMER ON TIMER OFF

TIMER ON-OFF

TIMER OFF-ON

0.5h

0.5h

0.5h

0.5h

Cancel TIMER OFF setting:

With a TIMER OFF set, press the CONFIRM/CANCEL

button once to cancel the TIMER OFF.

Turning the unit OFF with the TIMER from it being ON will look

like this on the remote control display:

Note:

Holding the TIMER OFF

button down will rapidly cycle

WIRELESS REMOTE CONTROLLER OPERATION