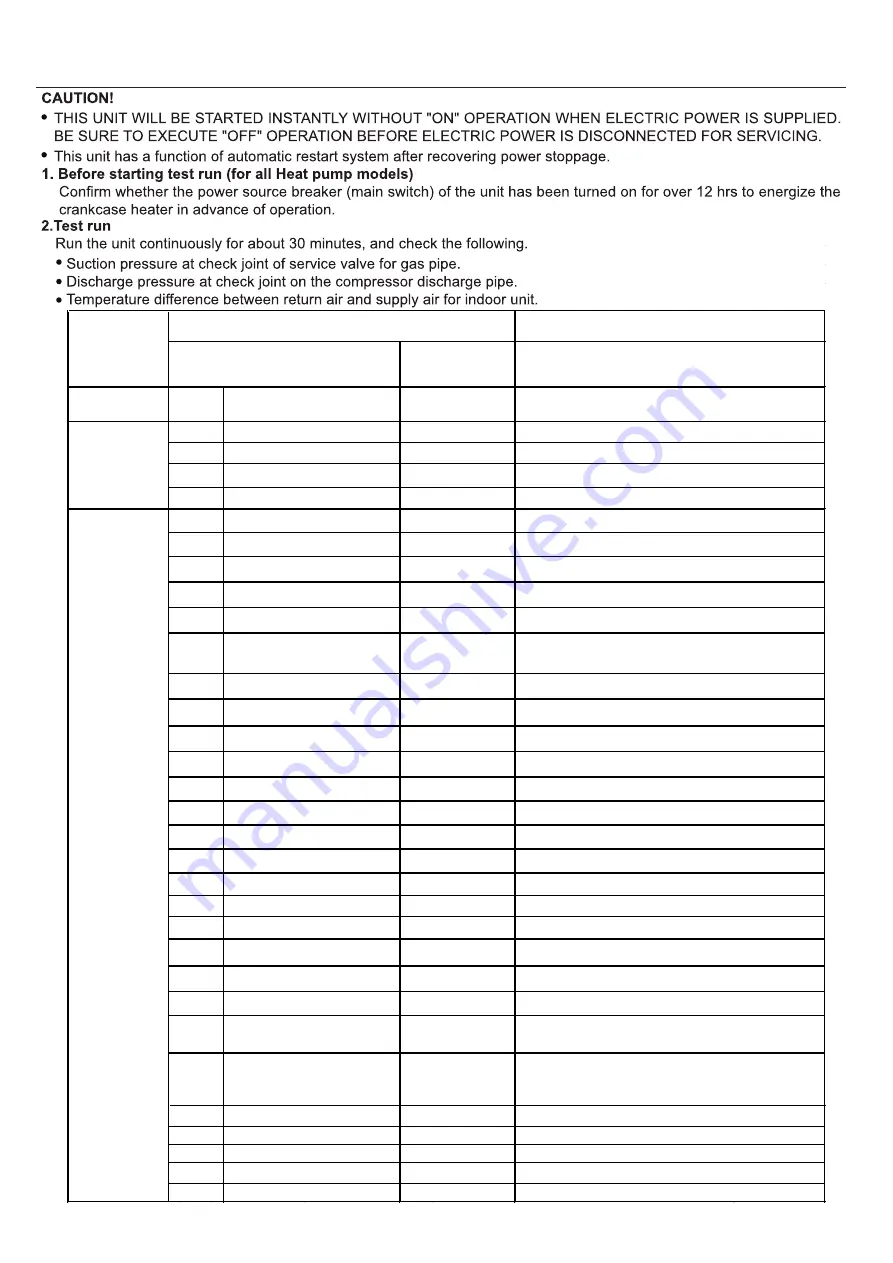

Outdoor Unit Troubleshooting

Code indication

Indoor displaying

panel code indication

Outdoor

fault description

(LED1 flash times)

Indoor and

15

Communication fault between indoor and outdoor

units

Outdoor

E7

Directly display

E1

Directly display

/

Indoor temperature sensor failure

Indoor

E2

Directly display

/

Indoor coil sensor failure

Malfunction

E4

Directly display

/

Indoor eeprom failure

E14

Directly display

/

Indoor fan failure

E5

Trouble record

22

Internal unit antifreeze protection

E9

Trouble record

21

Internal unit overload

F12

Directly display

1

Eeprom failure

F1

Directly display

2

IPM failure

F22

Directly display

3

AC current overcurrent protection

Communication error between module board

and main PCB board.

4

F3

Directly display

F20

Trouble record

5

High pressure protection

6

Power over/under voltage protection

F19

Trouble record

7

Compressor stall / press instantaneous stop

F27

Directly display

8

Compressor discarging temperature protection

F4

Directly display

F8

Trouble record

9

Abnormal of DC motor

F21

Directly display

10

Abnormal of piping sensor

F7

Directly display

11

Suction temperature sensor failure

Outdoor

Malfunction

12

Abnormal of outdoor ambient sensor

F6

Directly display

13

Abnormal of compressor discharge sensor

F25

Directly display

F13

Trouble record

16

Lack of refrigerant

F14

Trouble record

17

4-way valve reverse failure

F11

Directly display

18

Compressor jam (only for spdu)

F28

Directly display

19

Module PWM select circuit error

20

Outdoor terminal block temperature protection

F15

Trouble record

24

Instantaneous over-current protection of the

compressor

F2

Trouble record

Compressor U-phase overcurrent

Compressor V-phase overcurrent

Compressor W-phase overcurrent

25

F23

Trouble record

F9

Trouble record

26

Module reset

F24

Trouble record

27

CT disconnection

F34

Trouble record

37

Outdoor coil protection

F35

Trouble record

38

Compressor driver board failure

F43

/

46

Model matching abnormality

2

5

Summary of Contents for 1U22KAEFRA

Page 17: ...R32 15 Safety Precautions WARNING CAUTION N Open the window and well ventilated the room...

Page 19: ...R32 R32 R32 R32 R32 R32 R32 R32 R32 Read Before Installation 17...

Page 20: ...3 R32 R32 R32 R32 R32 R32 R32 Read Before Installation 18...

Page 21: ...R32 R32 R32 R32 R32 R32 R32 R32 10A HFC 410A Read Before Installation 19...

Page 24: ...Installation Procedure 22...

Page 25: ...evacuation degree Evacuate Installation Procedure 23...