Service Diagnosis

51

10.4.12

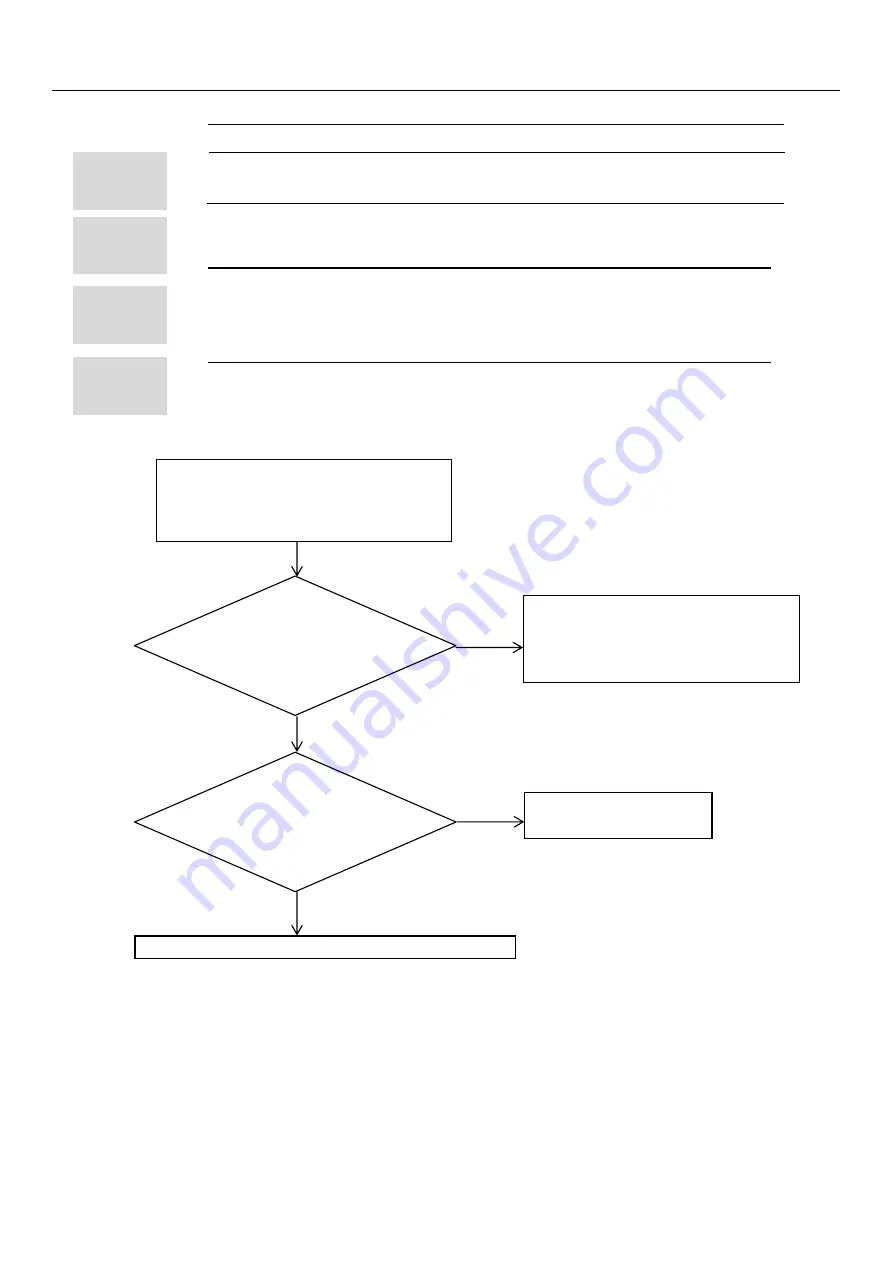

High work-intense protection

Outdoor display

E 9 LED1 flash 21 times

High work-intense control is activated in the heating mode if the temperature

being sensed by the heat exchanger thermistor exceeds the limit.

Activated when the temperature being sensed by the heat exchanger

rises above 65

℃

twice in 30 minutes

■

Faulty electronic expansion valve

■

Dirty heat exchanger

■

Faulty heat-exchange sensor

■

Insufficient gas

* Caution: Be sure to turn off power switch before connect or disconnect connector, or

parts damage may be occurred.

Trouble

shooting

Supposed

Causes

Malfunction

Decision

Conditions

Method of

Malfunction

Detection

The malfunction is reported

after the machine has run

for some time?

The indoor unit blows

poorly due to blocked

filters or poor condition of

the fan?

Use some tools to measure the pressure of system

Clean the filters

Reinstall the fan.

Check room temperature and pipe

temperature sensor.

Monitor the temperature of indoor

PCB circuits.

Electrify the machine again and turn it

on with the remote control, check

whether the wind temperature is below

65

℃

YES

NO

YES

NO