1. Do not connect the embedded branch piping and the outdoor unit when only carrying out piping work

without connecting the indoor unit in ordor to add another indoor unit later. Make sure that no dirt or

mositure gets into eigher side of the embedded branch piping.

2.It is impossible to connect the indoor unit for one room only. Be sure to connect at least 2 rooms.

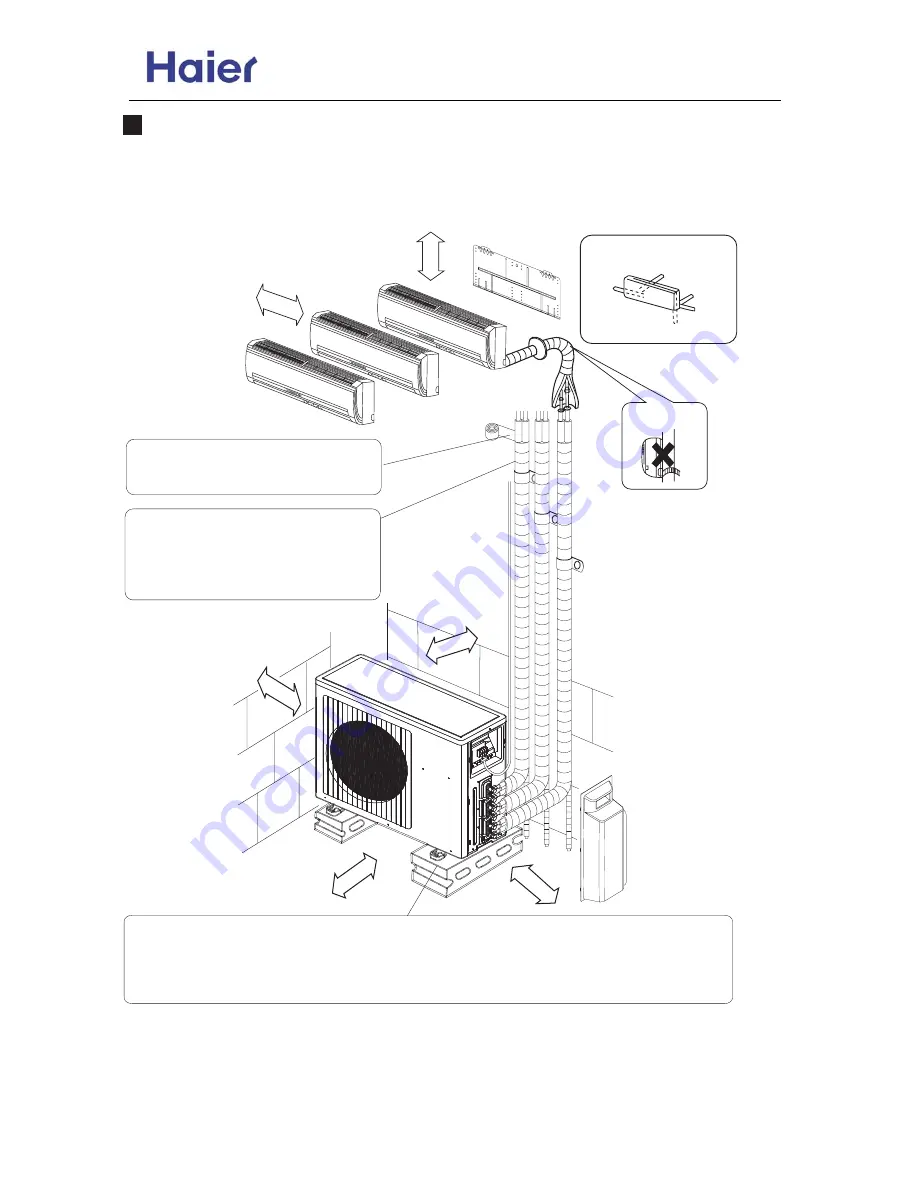

Installation drawings of indoor and outdoor units

Wrap the insulation pipe with the

finishing tape from bottom to top.

Cut thermal insulation pipe to an

appropriate length and wrap it with

tape, making sure that no gap is left in

the insulation pipe's cut line.

more than 10cm

more than 10cm

more than 60cm

more than 25cm

Arrangement of piping directions

If there is the danger of the unit failing or overturning, fix the unit with foundation bolts, or with wire or other

means.

If the location does not have good drainage, place the unit on a level mounting base(or a plastic pedestal).

Install the outdoor unit in a level position. Failure to do so may result in water leakage or accumulation.

Rear left

Rear right

Right

Below

Left

Attention must be

paid to the rising up

of drain hose

More than 5cm

More than 10cm

Commercial Air Conditioner

Model: AU18

/22

2XFERA

AS072/092/122XVERA

-18-