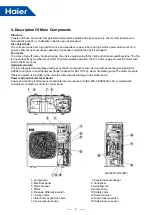

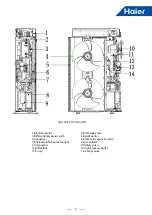

Summary of Contents for AU082FYCRA(HW)

Page 1: ...ATW Service Manual SYJS 03 2019REV A Edition 2019 03 ...

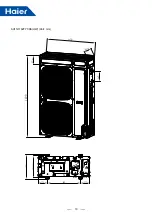

Page 11: ...9 405 410 600 174 174 450 950 965 395 6 Dimensions AU082FYCRA HW Unit mm ...

Page 12: ...10 AU112 162FYCRA HW Unit mm 1490 950 380 187 405 410 600 174 174 450 170 ...

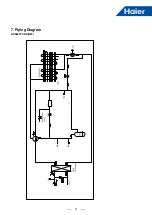

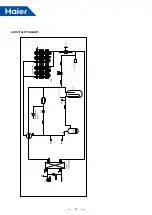

Page 13: ...11 AU082FYCRA HW 7 Piping Diagram ...

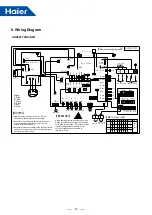

Page 14: ...12 AU112 162FYCRA HW ...

Page 27: ...25 12 Water Pressure Drop ...

Page 28: ...26 ...