SERVICE MANUAL

Model: BD-181SAA, BD-271SAA

14

Issue 2011-2-10

Rev.

Ref1102S001V0

Chapter 5 Control and display system

5-1. Control panel

Freezing temperature selection is made by setting the control from

min

to

max

(coldest).

If you want colder or warmer temperatures, adjust the control one step at a time.

Allow several hours after each one-step adjustment for the freezer temperature to stabilize.

5-2. Starting the Freezer

1. Clean the inside of the freezer with a mild solution of baking soda and water

2. Connect cord to power outlet.

3. Make sure the temperature control is set at 4.

4. Allow freezer to operate for at least four hours before placing food inside.

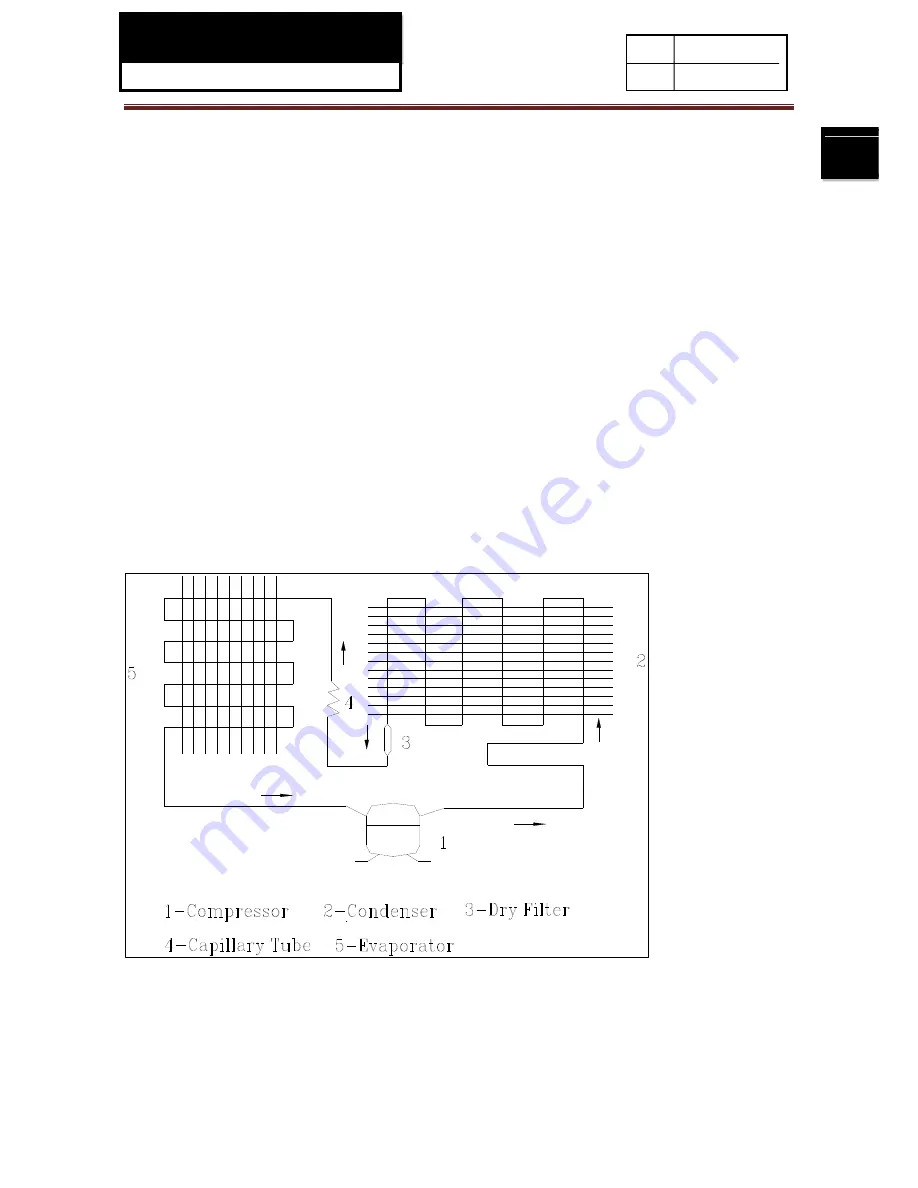

Chapter 6 System flow principle

6-1. Refrigeration flow chart

The refrigeration system of direct cooling single-system cooler belongs to the category of a

single-temperature and single-control refrigerating system with one evaporators and is controlled by

a single temperature control.