3

/

88

Content

●●

Designation ........................................................................................................................................... 5

●●

Introduction to product features ............................................................................................................ 6

●●

Product appearance ............................................................................................................................... 7

●●

Parts layout .......................................................................................................................................... 14

1. Display structure ........................................................................................................................... 14

2. Box structure ................................................................................................................................. 14

3. Electronic structure ....................................................................................................................... 17

4. System architecture....................................................................................................................... 20

●●

Cooling unit parts ................................................................................................................................. 21

●●

Refrigeration circuits ............................................................................................................................ 22

●●

Circuit diagram .................................................................................................................................... 23

●●

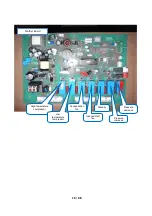

Connections on Main PCB ................................................................................................................... 25

●●

Specifications of sensor ....................................................................................................................... 26

1. The value of the probe resistance varies with temperature (probe type: NTC) ............................. 26

2. The value of the probe resistance varies with temperature (probe type: PT100) .......................... 27

●●

Detailed technical data of the product .................................................................................................. 28

●●

product nameplate ............................................................................................................................... 29

●●

Transportation and Installation ............................................................................................................. 30

1. Transportation of the product and removal of package ................................................................. 30

2. The product enters the placement room ........................................................................................ 31

3. Product installation and matters needing attention ........................................................................ 32

●●

Specifications of LCD panel ................................................................................................................. 35

1. Unlock ........................................................................................................................................... 35

2. Temperature setting ....................................................................................................................... 35

3. High Temperature Alarm ................................................................................................................ 36

4. Low Temperature Alarm ................................................................................................................ 36

●●

Indicating of working status of display panel ........................................................................................ 37

●●

Indication of alarm status ..................................................................................................................... 38

●●

Setting of special functions .................................................................................................................. 40

1. Setting of password value ............................................................................................................. 40

2. Setting of start delay...................................................................................................................... 40

3. Calibration function ....................................................................................................................... 40

4. Control of condensate fan ............................................................................................................. 40

Summary of Contents for DW-86L338

Page 7: ...7 88 Product appearance DW 86L388 486 628 728 828...

Page 8: ...8 88 DW 86L288 DW 86L338 388A...

Page 9: ...9 88 DW 86L490 DW 86W100...

Page 10: ...10 88 DW 86W420...

Page 11: ...11 88 Dimensions DW 86W100...

Page 12: ...12 88 DW 86L490...

Page 29: ...29 88 product nameplate For example DW 86L338...

Page 55: ...55 88 PICTURE 2 PICTURE 3 PICTURE 4 U Unit Pa 3Pa...