-------Internal training document for Haier service provider. External disclosure is prohibited --- Classification

30

30

sealing strip and the door to make air enter the freezer;

Second, goods placed by the user into the freezer contains water, which causes that water flows to the

sealing strip and the door gets frozen and cannot be opened. In this case, please use a tool to open the

door.

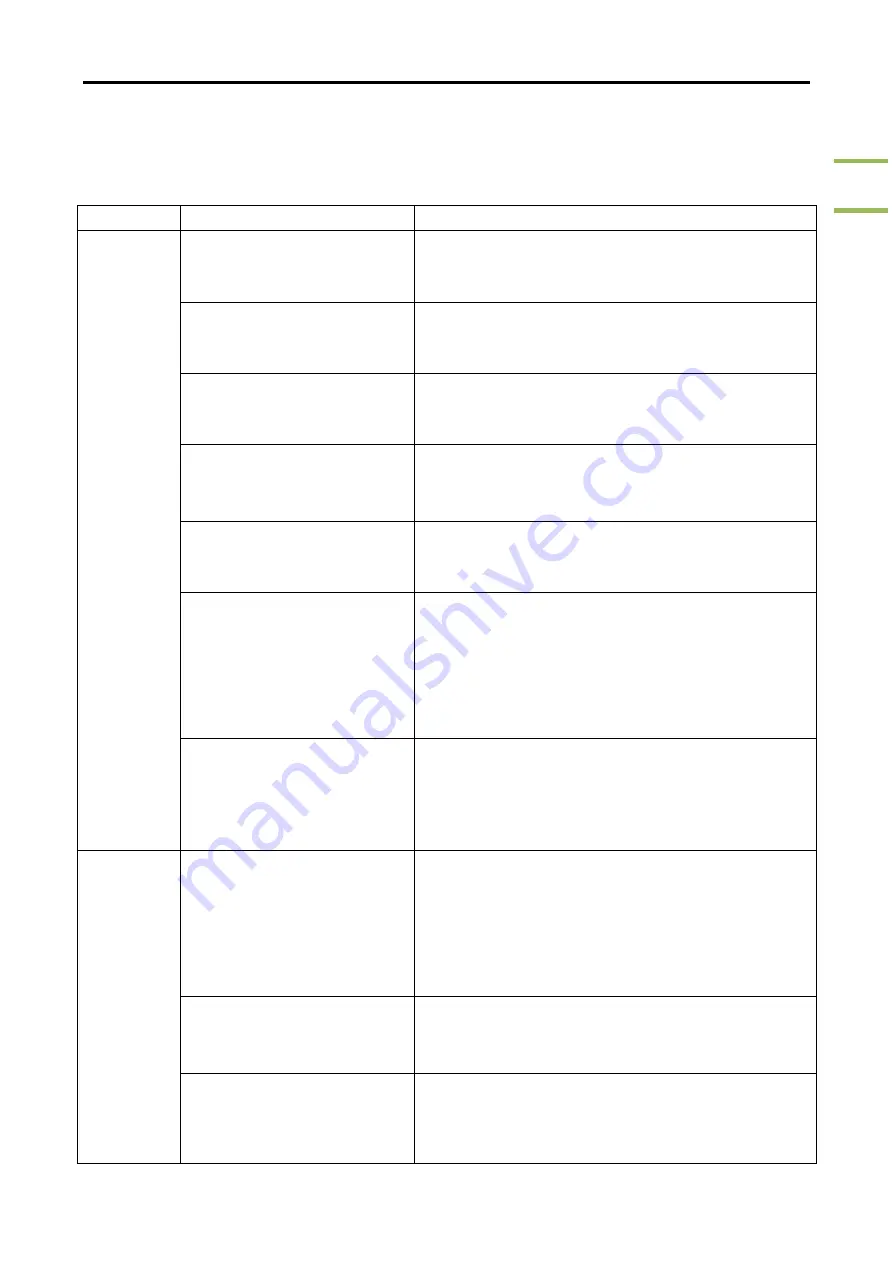

13.2 Common Q&A

Question

Reason Analysis

Maintenance Measures

1. The high

temperature

compressor

cannot start.

1. Power switch or fuse failure

Use the multi-meter to measure the switch or fuse

resistance and check if the switch is damaged. If so,

replace the fuse or power switch.

2. The plug-in part of the cabin is

damaged.

Check if the plug-in joint f the cabin circuit is damaged or

the harness falls down. If so, replace the relevant harness.

3. Line contact failure

Check if the power harness is connected improperly or

disconnected. If so, repair it until it is connected normally.

4.Display panel and control

panel circuit failure

Use the multi-meter to measure the circuit resistance and

check if the harness has a short circuit or open circuit

failure. If so, replace the harness if it is impossible to

maintain it.

5. Relay, starting capacity or

thermal protector damage

Check the relay, capacitance or heat protector/. Check if

any electric part is burnt. If so, replace the electric part.

6. Compressor failure

On condition that other parts are switched on normally,

check if the connection plug of the compressor is normal.

Meanwhile, observe the surface temperature and

abnormal noise of the compressor. If the compressor does

not heat up or the makes abnormal noise, it is damaged

and shall be replaced; when it is changed, the oil

separator and the dry filter shall also be changed at the

same time.

7. Too low voltage of the user

Check if the display panel voltage of the product is

covered in the rated voltage scale (220V±10%).

Meanwhile, use a multi-meter to measure and check if the

voltage exceeds the scope when the power is switched on

for operation. If the voltage is too low or too high, please

prepare a stable voltage supercharger.

2. The low

temperature

compressor

cannot start.

1. The same reason for starting

failure of the high temperature

compressor

On condition that other parts are switched on normally,

check if the connection plug of the compressor is normal.

Meanwhile, observe the surface temperature and

abnormal noise of the compressor. If the compressor does

not heat up or the makes abnormal noise, it is damaged

and shall be replaced; when it is changed, the oil

separator and the dry filter shall also be changed at the

same time.

2. Pressure switch failure

Use the multi-meter to measure the resistance of the

circuit and check if the harness has a short circuit or open

circuit failure. Then, replace the harness if it is impossible

to maintain it.

3.

Poor

refrigeration

performance of high temperature

compressor

If the low temperature compressor fails to start after the

high temperature compressor is started for 10min., it

means the high temperature compressor has poor

refrigeration performance. In this case, check if the circuit

and pipeline of the high temperature system are welded

Summary of Contents for DW-86L486

Page 36: ......