507769-05G / 31-5000656

Page 45 of 55

Issue 2223

Other Unit Adjustments

Primary Limit

The primary limit is located on the heating compartment

vestibule panel. This limit is factory set and requires no

adjustment.

Flame Rollout Switches (Two)

These manually reset switches are located on the front of

the burner box. These limits are factory set and require no

adjustment.

Pressure Switch

The pressure switch is located in the heating compartment

on the cold end header box. This switch checks for proper

combustion air inducer operation before allowing ignition

trial. The switch is factory set and must not be adjusted.

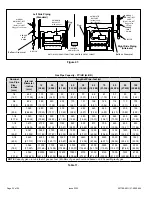

Temperature Rise

After the furnace has been started and supply and return

air temperatures have been allowed to stabilize, check

the temperature rise. If necessary, adjust the blower

speed to maintain the temperature rise within the range

shown on the unit nameplate. See Table 21 for allowable

heating speeds. Increase the blower speed to decrease

the temperature. Decrease the blower speed to increase

the temperature rise. Failure to adjust the temperature rise

may cause erratic limit operation.

Fan Control

Ignition Control 103217-03

The fan on time of 45 seconds is not adjustable. The heat

fan off delay (amount of time that the blower operates after

the heat demand has been satisfied) may be adjusted by

changing the jumper position across the five pins on the

integrated control. The unit is shipped with a factory fan

off delay setting of 90 seconds. The fan off delay affects

comfort and is adjustable to satisfy individual applications.

Adjust the fan off delay to achieve a supply air temperature

between 90° and 110° F at the moment that the blower

is de-energized. Longer off delay settings provide lower

return air temperatures; shorter settings provide higher

return air temperatures. See Figure 56.

Ignition Control 107163-01

The heat fan-on time of 30 seconds is not adjustable The

heat fan-off delay (amount of time that the blower operates

after the heat demand has been satisfied) may be adjusted

by changing the two position dip switch on the integerated

control, to one of four slections. Blower off delay is factory

set at 90 seconds. For other blower off delay settings,

SW2-1

SW2-2

60

OFF

ON

90*

OFF

OFF

120

ON

OFF

180

ON

ON

* Factory setting

Table 20. Blower Delay Select

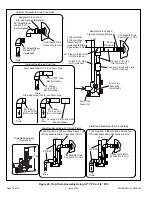

Figure 56.

Heat Fan Off Time in Seconds

To adjust fan-off timing, reposition jumper across pins to

achieve desired setting.

NO JUMPER

60 90

12

0

180

60 90

12

0

180

60 90

12

0

18

0

60 90

12

0

18

0

60 Second

off Time

90 Second

off Time

120 Second

off Time

180 Second

off Time

Constant Torque Motor

These units are equipped with a constant torque ECM

motor. It has a DC motor coupled to an electronic control

module,both contained in the same motor housing. The

motor is programmed to provide constant torque at each of

the five selectable speeds. The motor has five speed taps.

Each tap requires 24 volts to energize.

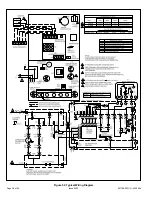

Thermostat Heat Anticipation

Set the heat anticipator setting (if adjustable) according to

the amp draw listed on the wiring diagram that is attached

to the unit.

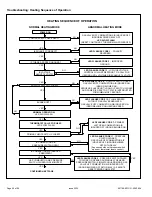

Exhaust and Air Intake Pipe

1.

Check exhaust and air intake connections for tightness

and to make sure there is no blockage.

2.

Is pressure switch closed? Obstructed exhaust pipe

will cause unit to shut off at pressure switch. Check

termination for blockages.

3. Obstructed pipe or termination may cause rollout

switches to open. Reset manual flame rollout switches

on burner box assembly if necessary.

Electrical

1. Check all wiring for loose connections.

2. Check for the correct voltage at the furnace (with

furnace operating). Correct voltage is 120 VAC ± 10%.

3. Check amp–draw on the blower motor with the blower

compartment access panel in place.

Motor Nameplate____________ Actual____________