507962-01G / 31-5000654

Page 12 of 51

Issue 2149

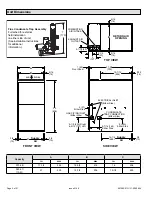

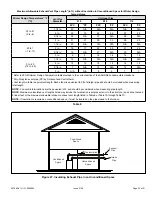

Figure 18.

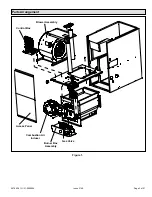

Figure 19.

Filters

This unit is not equipped with a filter or rack. A field provided

filter is required for the unit to operate properly. Table 3 lists

recommended filter sizes.

A filter must be in place whenever the unit is operating.

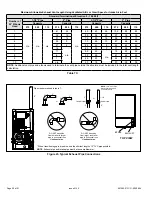

Table 3.

Furnace Cabinet Width

Filter Size

17-1/2”

16 x 25 x 1 (1)

21”

Duct System

Use industry-approved standards to size and install the

supply and return air duct system. This will result in a quiet

and low-static system that has uniform air distribution.

NOTE:

This furnace is not certified for operation in heating

mode (indoor blower operating at selected heating speed)

with an external static pressure which exceeds 0.8 inches

w.c. Operation at these conditions may result in improper

limit operation.

Supply Air Plenum

If the furnace is installed without a cooling coil, a removable

access panel should be installed in the supply air duct. The

access panel should be large enough to permit inspection

(by reflected light) of the heat exchanger for leaks after the

2.

After opening is cut, set the combustible flooring base

into opening.

3.

Check fiberglass strips on the combustible flooring

base to make sure they are properly glued and

positioned.

4.

Lower supply air plenum into the combustible flooring

base until plenum flanges seal against fiberglass

strips.

NOTE:

Be careful not to damage fiberglass strips.

Check for a tight seal.

5. Set the furnace over the plenum.

6. Ensure that the seal between the furnace and plenum

is adequate.

Installation on Cooling Coil Cabinet

NOTE:

Downflow combustible flooring kit is not used.

1.

Refer to reverse-flow coil installation instructions for

correctly sized opening in floor and installation of

cabinet.

2. When cooling cabinet is in place, set and secure the

furnace according to the instructions that are provided

with the cooling coil. Secure the furnace to the cabinet.

3. Seal the cabinet and check for air leaks.

Figure 17.

Return Air Opening - Downflow Units

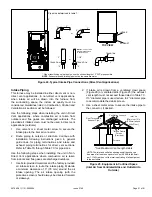

Return air may be brought in only through the top opening of

a furnace installed in the downflow position. The following

steps should be taken when installing plenum:

1.

Bottom edge of plenum should be flanged with a

hemmed edge (see Figure 18 or Figure 19).

2. Sealing strips should be used to ensure an airtight

seal between the cabinet and the plenum.

3. In all cases, plenum should be secured to top of

furnace using sheet metal screws.

4. Make certain that an adequate seal is made.