507962-01G / 31-5000654

Page 46 of 51

Issue 2149

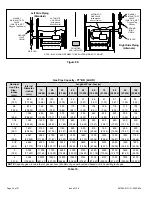

Blower Performance

Model

Temp Rise

Speed

Adjustment

Heating CFM @ 0 - 0.8” w.c.

Setting “D”

Setting “C”

Setting “B”

Setting “A”

NF96D070V4B

High Fire

35 - 65

+

1110

1305

1430

1700

Normal

995

1175

1315

1520

-

880

1055

1170

1365

Low Fire

20 - 50

+

860

1020

1140

1340

Normal

795

910

1030

1230

-

680

825

910

1085

Cooling

Stage

Speed

Adjustment

Cooling CFM @ 0 - 0.8” w.c.

Setting “D”

Setting “C”

Setting “B”

Setting “A”

2nd Stage

+

1110

1340

1575

1800

Normal

995

1230

1420

1650

-

880

1085

1290

1460

1st Stage

+

740

915

1055

1255

Normal

660

820

940

1120

-

575

735

850

995

Model

Temp Rise

Speed

Adjustment

Heating CFM @ 0 - 0.8” w.c.

Setting “D”

Setting “C”

Setting “B”

Setting “A”

NF96D090V5C

High Fire

35 - 65

+

1395

1555

1695

1825

Normal

1275

1395

1585

1670

-

1145

1265

1405

1525

Low Fire

25 - 55

+

1130

1230

1365

1475

Normal

1040

1130

1250

1340

-

910

1025

1130

1210

Cooling

Stage

Speed

Adjustment

Cooling CFM @ 0 - 0.8” w.c.

Setting “D”

Setting “C”

Setting “B”

Setting “A”

2nd Stage

+

1335

1600

1750

1980

Normal

1225

1450

1630

1830

-

1120

1270

1450

1660

1st Stage

+

955

1115

1265

1450

Normal

855

1005

1150

1285

-

750

890

1060

1170