Page 13

31-5000723 Rev. 0

Operation

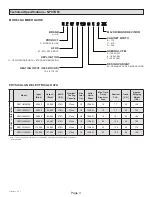

Thermostat

Switch 1

Switch 2

Switch 3

Variable Capacity Heat

(40% to 100%)

Two-Stage

Off

On

Off

Three-Stage Heat

(40%, 70%, 100%)

Single-Stage

On

Off

2nd Stage Delay

OF = 7 minutes

ON = 12 minutes

3rd Stage Delay

10 minutes fixed

Two-Stage Heat

(W1 70%, W2 100%)

Two-Stage

Off

Off

Off

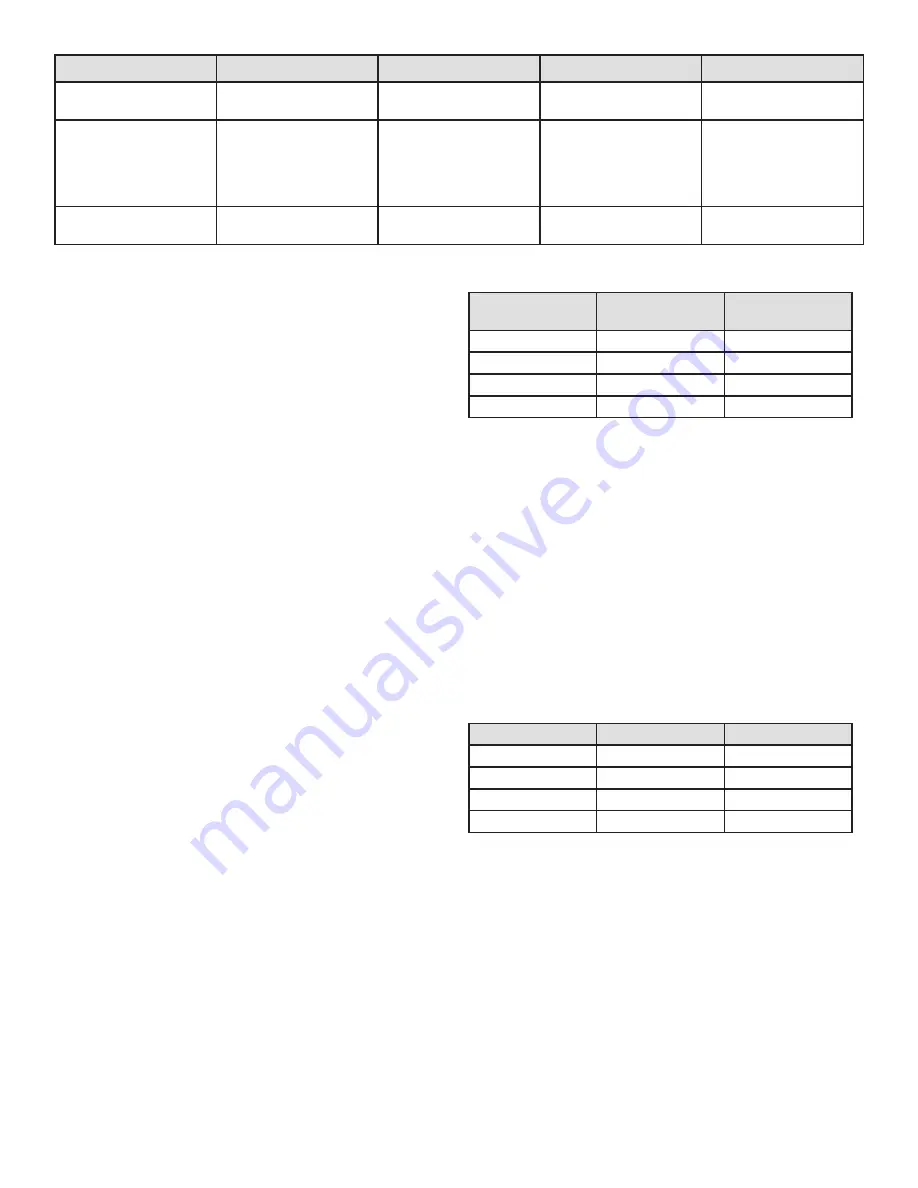

Table 3. Thermostat Selection Switch Settings

Heating Operation DIP Switch Settings -- Figure 4

Switch 1 -- Thermostat Selection --

This unit may be

used with either a single-stage or two-stage thermostat.

The thermostat selection is made using a DIP switch which

must be properly positioned for the particular application.

The DIP switch is factory-positioned for use with a two-stage

thermostat. If a single-stage thermostat is to be used, the

DIP switch must be repositioned. See Table 3.

NOTE:

All DIP switches are factory shipped in the “OFF”

position.

Switch 2 -- Operating Mode with Two-Stage Thermostat

--

If a two-stage thermostat is used, the furnace can operate

in either variable-capacity or conventional two-stage mode.

When variable-capacity mode is selected, the firing rate

of the unit is varied to maximize comfort. Conventional

twostage mode is the factory default setting. See Table 3.

Switch 3 -- Second-Stage Heat On Delay --

If a singlestage

thermostat is used, the integrated control can be used to

energize second-stage heat after either 7 minutes or 12

minutes of first-stage heat operation. See Table 3.

Switches 4 and 5 -- Blower-Off Delay --

The blower-on

delay of 45 seconds is not adjustable. The blower-off delay

(time that the blower operates after the heating demand

has been satisfied) can be adjusted by moving switches 4

and 5 on the integrated control. The unit is shipped from the

factory with a blower-off delay of 90 seconds. The blower off

delay affects comfort and is adjustable to satisfy individual

applications. Adjust the blower off delay to achieve a supply

air temperature between 90° and 110°F at the exact moment

that the blower is de-energized. Longer off delay settings

provide lower supply air temperatures; shorter settings

provide higher supply air temperatures. Table 4 provides

the blower off timings that will result from different switch

settings.

Blower Off Delay

(Seconds)

Switch 4

Switch 5

60

Off

On

90 (Factory)

Off

Off

120

On

Off

180

On

On

Table 4.

Blower Off Delay Switch Settings

Switches 6 and 7 - Continuous Indoor Fan Operation

-

Blower Speed

- The unit is shipped from the factory with the

DIP switches positioned for medium low (38%) speed during

continuous indoor blower operation. Continuous fan setting

is 38% of cool setting and is not adjustable.

Switches 8 and 9 -- Cooling Mode Blower Speed --

Switches 8 and 9 are used to select cooling blower motor

speed. The unit is shipped from the factory with the DIP

switches positioned for high speed (4) indoor blower motor

operation during the cooling mode. Table 5 provides the

cooling mode blower speeds that will result from different

switch settings. Refer to blower tables at the front of this

manual for corresponding cfm values.

Speed

Switch 8

Switch 9

1 - Low

On

On

2 - Medium Low

Off

On

3 - Medium High

On

Off

4 - High (Factory)

Off

Off

Table 5. Cooling Mode Blower Speeds

Switches 10 and 11 -- Cooling Mode Blower Speed

Adjustment --

Switches 10 and 11 are used to select

blower speed adjustment settings. The unit is shipped from

the factory with the DIP switches positioned for NORMAL

(no) adjustment. The DIP switches may be positioned to

adjust the blower speed by +10% or -10% to better suit the

application. Table 6 provides blower speed adjustments

that will result from different switch settings. Refer to blower

tables at the front of this manual for corresponding cfm

values. With switches 10 and 11 set to ON, motor will bypass

ramping profiles and all delays and immediately upon a call

for cool, run at COOLING speed selected. LED will continue