English

3.8 Connecting the Refrigerant Tubing

CAUTIONS DURING BRAZING

Replace air inside the tube with nitrogen gas to prevent copper oxide film from forming during the brazing process. (Oxygen, carbon dioxide

and Freon are not acceptable.)

●

Do not allow the tubing to get too hot during brazing.The nitrogen gas inside the tubing may overheat, causing refrigerant system valves to

become damaged. Therefore allow the tubing to cool when brazing.

●

Use a reducing valve for the nitrogen cylinder.

●

Do not use agents intended to prevent the formation of oxide film. These agents adversely affect the refrigerant and refrigerant oil, and may

cause damage or malfunctions.

TIGHTENING

In the table below are shown the pipes diameter for each unit

For the flare nuts at tubing connections, be sure to use the flare nuts that were supplied with the unit, or else flare nuts for R410A. The refrige-

rant tubing that is used must be of the correct wall thickness as shown in the table below.

Because the pressure is approximately 1.6 times higher than conventional refrigerant pressure, the use of ordinary flare nuts or thin-walled

tubes may result in tube rupture, injury, or asphyxiation caused by refrigerant leakage.

●

In order to prevent damage to the flare caused by overtightening of the flare nuts, use the table above as a guide when tightening.

●

When tightening the flare nut on the liquid tube, use an adjustable wrench with a nominal handle length of 200 mm.

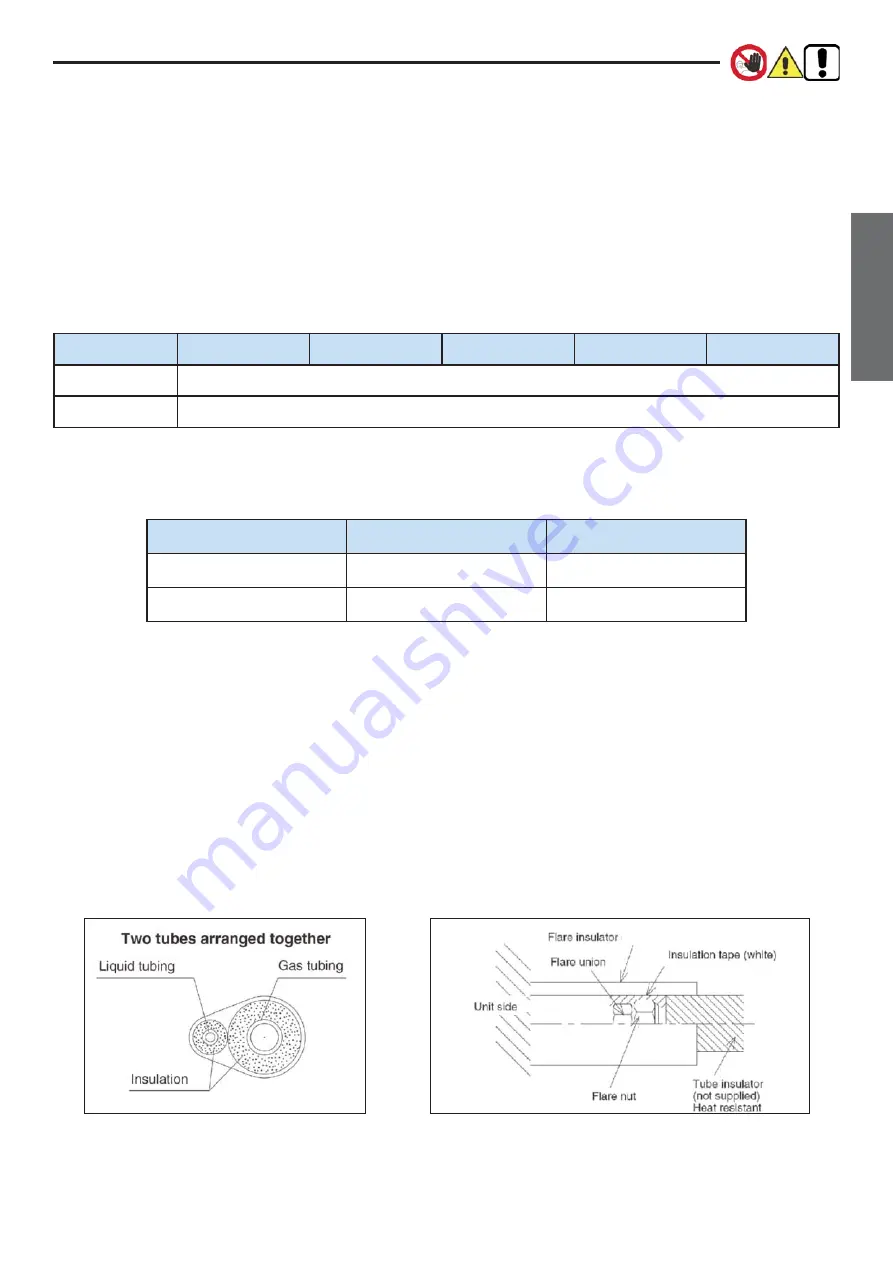

INSULATING THE REFRIGERANT TUBING

Thermal insulation must be applied to all units tubing, including distribution joint (field supply). For gas tubing, the insulation material must be

heat resistant to 120°C or above. For other tubing, it must be heat resistant to 80°C or above.

Insulation material thickness must be 10 mm or greater.

If the conditions inside the ceiling exceed DB 30°C and RH 70%, increase the thickness of the gas tubing insulation material by 1 step.

ø Tube

Tightening torque

Tube thickness

ø 6,35 (1/4”)

14 - 18 N*m

0,8 mm

ø 12,7 (1/2)”

49 - 55 N*m

0,8 mm

Installation, Use and Maintenance Manual - HACI-RP DX series

pag. 41

Unit

HACI-RP DX 050

HACI-RP DX 065

HACI-RP DX 080

HACI-RP DX 100

HACI-RP DX 130

Gas line

ø 12,7 mm

Liquid line

ø 6,35 mm

Summary of Contents for HACI-RP DX 100

Page 52: ...2020 06 ...