13

Troubleshooting

The following circumstances do not constitute problems. Do not contact the maintenance service

until the

problem has been confirmed.

Problem

Possible cause

The washing machine fails to operate

Poor connection to power supply

Power failure

Door is not properly closed (It will show E1)

Machine has not been switched on

Washing machine cannot be filled

with water

Water tap is not turned on (It will show E5)

Water pressure is less than 0.05Mpa

The inlet hose is kinked

Water supply failure

The program dial is not properly set

The door is not properly closed

The inlet hose filter is blocked

The machine is draining while is

being filled

The height of the drainage hose is below 80cm (it

should be within 80-100cm)

The drainage hose end is in water

Drainage failure

Drainage hose is blocked (It will show E2)

Drainage hose end is below 100cm above the floor

level

The filter is blocked

Strong vibration during spin drying

Not all packing bolts have been removed

Washing machine is located on an uneven surface

Machine load is over 6kg.

Not all foam packing has been removed from the motor

Operation stops before completion

of a wash cycle

Water or electricity failure

Washing machine is in soak cycle

Operation stops for a period of time

Washing machine is in soak cycle

Washing machine gives an error message.

Excessive foam in the drum, which

spilled to the distribution drawer

The detergent is not a low-foaming type or for manual

wash

Excessive use of detergent

4

ƽ

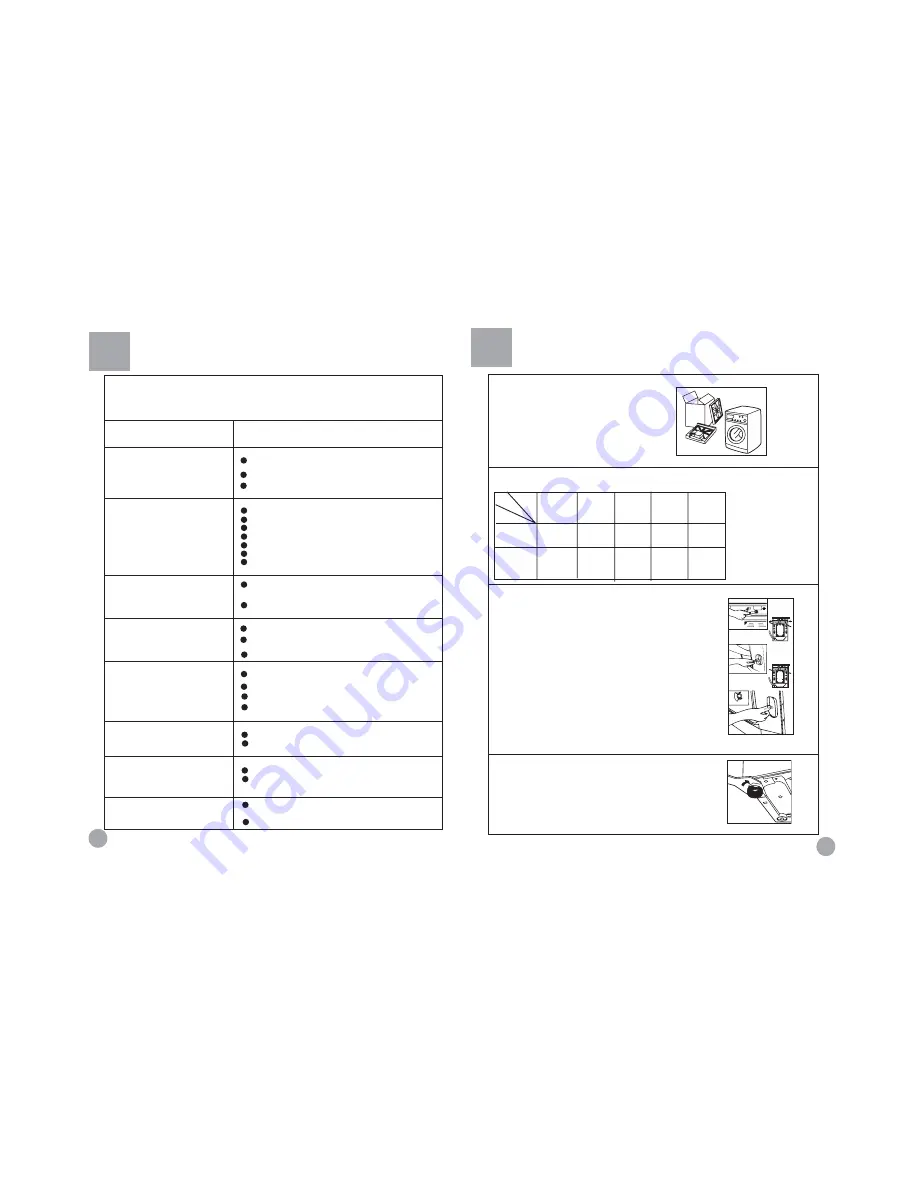

Remove all the packing materials (including the

foam base)to prevent vibration during use, as

shown in Fig.1.Upon opening of the package,

water drops may be seen on the plastic bag and

the porthole. This is normal phenomenon resulting

from water test in the factory.

Fig

. 1

ƽ

Check attachments and materials with reference to the following

ƽ

Dismantle the packing bolts as shown in Fig. 2.

The packing bolts are designed for clamping anti-vibration components

inside of the washing machine during the transportation process.

Beforeuse:

1. Remove the back plate;

2. Remove the three packing bolts on the back plate and take out the

rubber hose;

3. Replace the back plate;

4. Fill the holes left by the packing bolts with plastic plugs.

(Attention: The packing bolts and rubber hose should be kept in a safe

place for later use)

Fig.3

ƽ

Adjusting the washing machine

There are adjustable feet under the bottom of the washing machine. Before

use, the washing machine should be adjusted, as shown in Fig. 3, so that it

is level.

Fig.2

Model

HK1600TXVE/ME

HK1400TXVE/ME

Qty

Name

Operation

manual

1

1

1

1

4

Quality

certificate

Water

hose

Drainage

holder

Plastic

plugs

Installation

HK1200TXVE/ME

HK1000TXVE/ME

HK800TXVE/ME

1

1

1

1

3