10

MAINTENANCE SERVICE AND TROUBLE SHOOTING

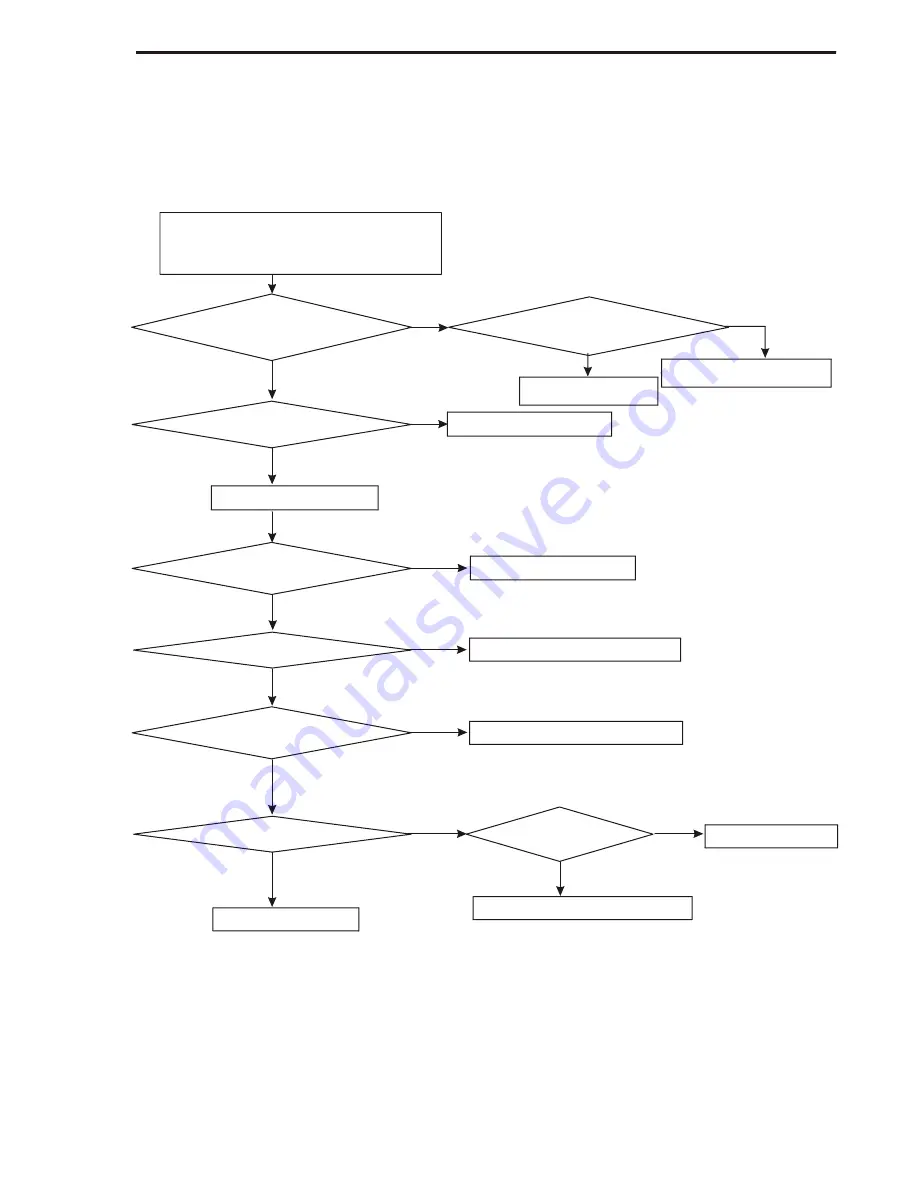

If you replace the computer sequencer without checking the other components carefully, the

computer sequencer may be damaged again. Therefore, please first check if the other components

working normally before replacing the sequencer in maintenance.

No washing and No water filling

C

Trouble-shooting charts

Replace the sequencer

Replace the power cord

Replace the door switch

Repair or replace the wire unit

Check the transmission system.

Replace the motor

Repair the capacity

Repair or replace the wire unit

Pull out the power cord

Replace the water inlet valve

Confirm that there's no power failure, pull the

power plug out and insert it tightly again. Then

close the top lid , turn the sequencer knob to the

wash location and pull it out

Measure the voltage of

white & black wires of the two ends of the power

input of the sequencer

Measure the voltage of

the two ends of the power cord

Measure the voltage of

the door switch with the top lid

close

Insert the

plug and measure the voltage of

two ends of the motor

Check if the wire unit is normal?

Check if the capacity is normal?

Check if the motor is action?

Measure the voltage of

the two ends of the water inlet valve

Yes

No

Infinite

No

No

Yes

No

Yes

No

No

Yes

Yes

Yes

Yes

No

The resistance is 0