4

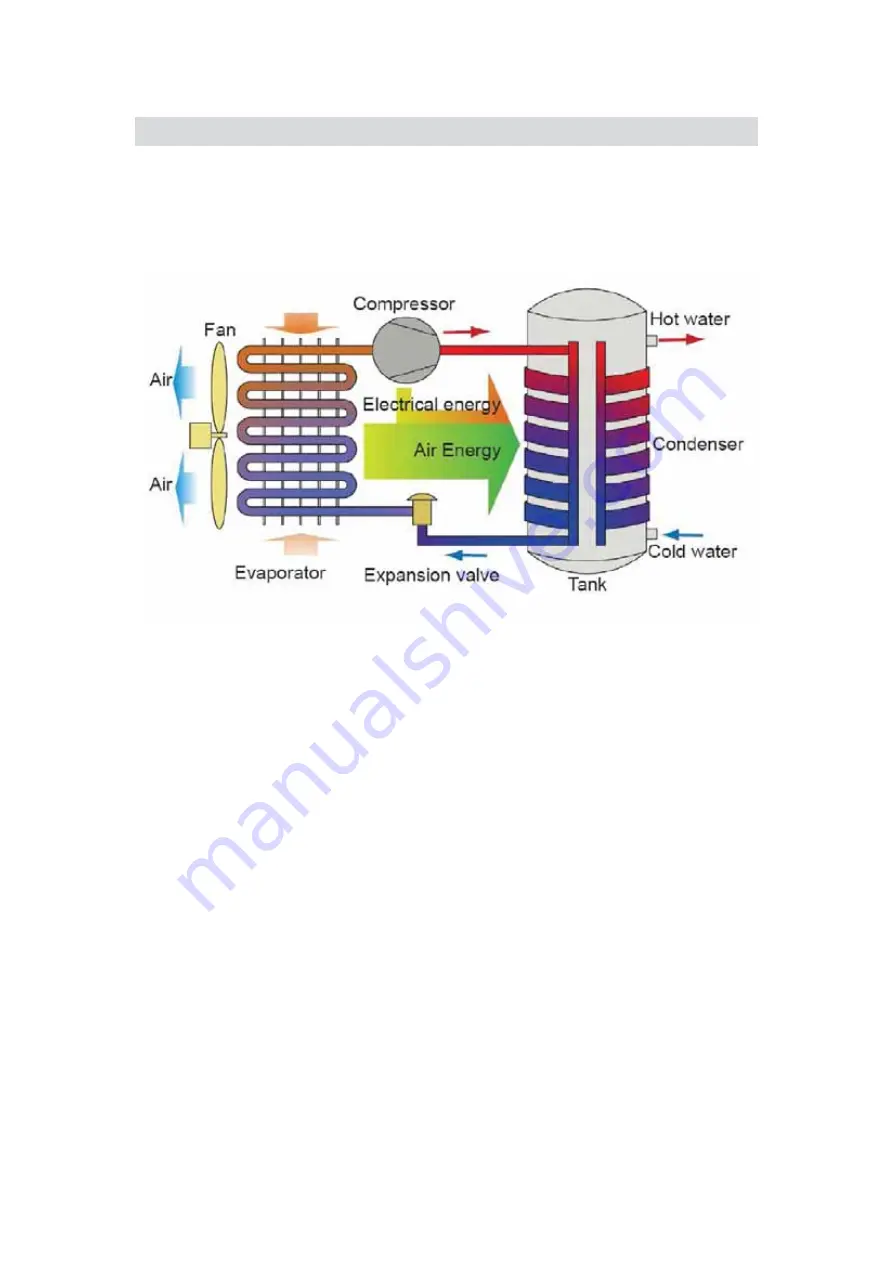

2. Functionings & principles

A low-pressure liquid refrigerant is vaporized in the heat pump's evaporator and passed into the

compressor. As the pressure of the refrigerant increases, so does its temperature. The heated

refrigerant runs through a condenser coil within the storage tank, transferring heat to the water

stored there. As the refrigerant delivers its heat to the water, it cools and condenses, and then

passes through an expansion valve where the pressure is reduced and the cycle starts over.

Summary of Contents for HP200S1

Page 5: ...5 3 Technical parameters ...

Page 6: ...6 4 Description of parts and components 4 1 Heat pump structure HP200 300S1 ...

Page 7: ...7 4 2 Exploded view 4 2 1 Exploded view tank unit ...

Page 13: ...13 5 2 Installation dimensions mm ...

Page 21: ...21 ...

Page 23: ...23 5 13 Wiring diagram ...

Page 24: ...24 6 Operation and functions Display 6 1 Description of the pictograms ...

Page 25: ...25 ...

Page 29: ...29 8 Faults and protection 8 1 Fault type ...

Page 30: ...30 8 2 Fault code identification method ...

Page 31: ...31 ...

Page 32: ...32 ...

Page 33: ...33 ...

Page 37: ...37 9 2 Remove the Control panel Use a screwdriver to remove the screws Remove it Remove it ...