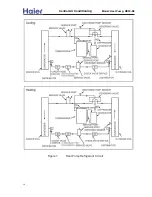

OUTDOOR UNIT INSTALLATION

………….Unit level with proper clearances for air flow and service

…………..Proper elevation of outdoor unit

…………..Solid pad

REFRIGERANT LINES

………….Proper length according to manufacturer’s instructions

…………..Proper size according to manufacturer’s instructions

…………..Large vapor line insulated

INDOOR UNIT INSTALLATION

…………..Air ducts sealed to prevent leakage

…………. Proper air flow (about 400 CFM per ton)

…………. Condensate line piped with trap and vent

…………. Auxiliary drain pan installed in horizontal applications

…………. Auxiliary condensate line installed in horizontal application

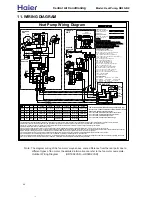

CAPACITOR ELECTRICAL CHECK

two windings out of phase from one another and allows the compressor motor to start. Use a capacitor

capacitor plates

1. Set the ohmmeter to the highest scale available

2. Discharge the capacitor by shorting the terminals with the blade of a screwdriver having an insulated

handle.

3.

capacitor is GOOD

4. Replace any failed capacitor with a capacitor having the same MFD and voltage rating.

COMPRESSOR START KITS

…………..No evidence of refrigerant leaks

…………..Coil free from dirt and debris

…………..No inadvertent oil traps and proper sloping

…………..No evidence of refrigerant leaks

…………..Unit charged according to manufacturer’s instructions

…………..No kinks or restrictions

…………..Adequate clearances for air flow and service

…………. No evidence of refrigerant leaks

…………..Proper supply and return air duct size and design

…………..Correct filter(s)

…………. Correct indoor coil and accessories

…………..External static pressure_____ inches W.C.

…………..Horizontal drain pan installed in horizontal applications

WARNING: ANY CAPACITOR SHOWING SIGNS OF LEAKAGE OR BULDGING MUST BE

REPLACED IMMEDIATEDLY. DO NOT OPERATE THE AIR CONDITIONING SYSTEM WITH A

CAPACITOR SHOWING THESE SIGNS.

tester to determine if the capacitor dielectric has broken down, or if the MFD value has changed. If a

Single phase compressors require a run capacitor connected to the run and start windings. This puts the

capacitor analyzer is not available, use a quality ohmmeter to check the resistance between the

Place the Ohmmeter probes on the capacitor terminals and observe:

B. If the meter pointer does not move, the Open capacitor is open and should be REPLACED.

A. If the meter pointer moves towards zero, then gradually moves to higher ohm values, the

C. If the meter pointer goes toward ZERO ohms and stays at or near zero, the capacitor is shorted

and should be replaced.

25

Central Air Conditi

oning

Model: Heat Pump,

HR13-D2