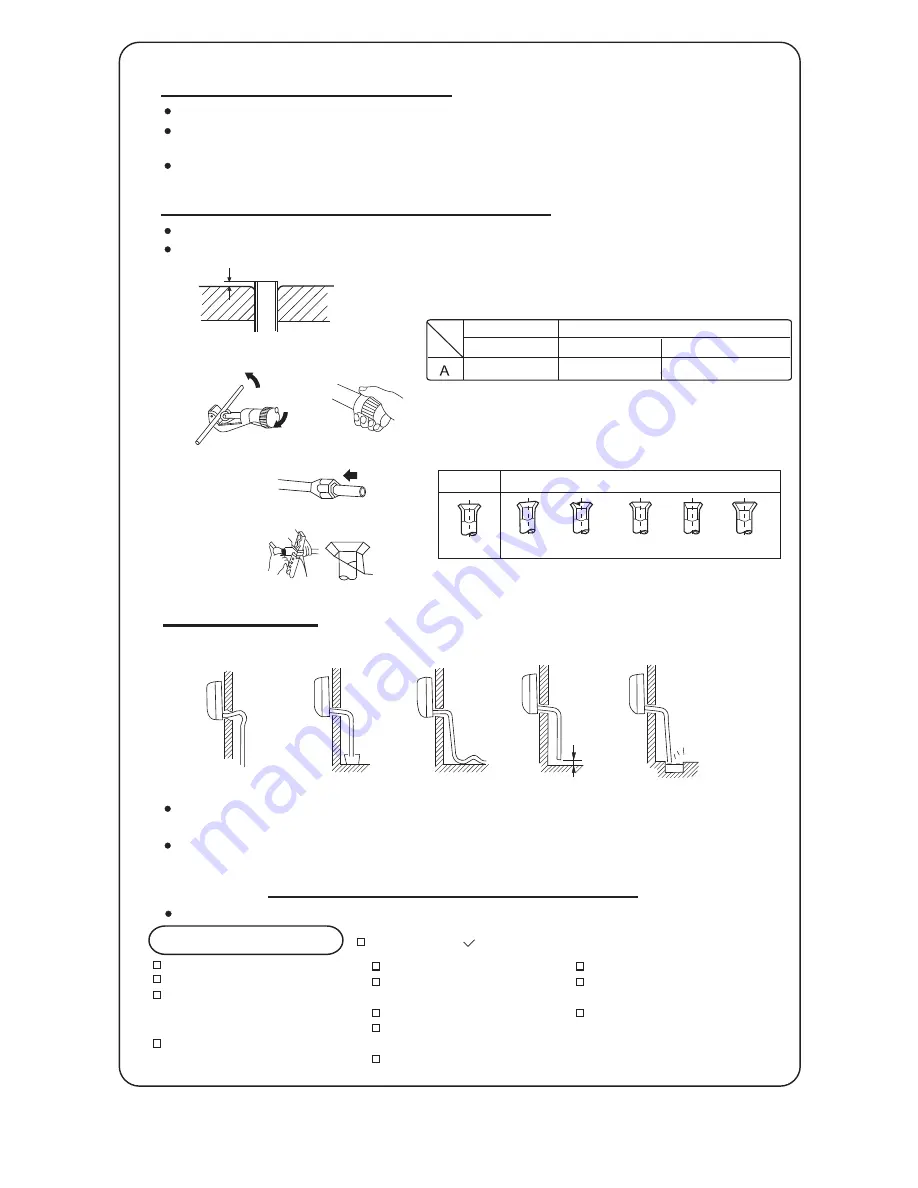

1.Cut pipe

3.Insert the flare nut

4.Flare pipe

It becomes high

midway.

The end is immersed

in water.

It waves.

The gap with the ground

is too small

Less than 5cm

There is the bad smell

from a ditch

2.Remove burs

0~0.5mm

1.0~1.5mm

1.5~2.0mm

Flare tool for R410A

Clutch-type

Conventional flare tool

clutch-type(Rigid-type) Wing-nut type (Imperial-type)

1.Power Source Installation

2.Cutting and Flaring Work of Piping

3.On Drainage

Check for Installation and Test Run

Check Items for Test Run

The power source must be exclusively used for air conditioner. (Over I0A)

In the case of installing an air conditioner in a moist place, please install an

earth leakage breaker.

For installation in other places, use a circuit breaker as far as possible.

Pipe cutting is carried out with a pipe cutter and burs must be removed.

After inserting the flare nut, flaring work is carried out.

Please install the drain hose so as to be downward slope without fail.

Please don't do the drainage as shown below.

Please pour water in the drain pan of the indoor unit, and confirm that drainage is

carried out surely to outdoor.

In case that the attached drain hose is in a room, please apply heat insulation

to it without fail.

Please kindly explain to our customers how to operate through the instruction manual.

Gas leak from pipe connecting?

Heat insulation of pipe connecting?

Are the connecting wirings of

indoor and outdoor firmly inserted

to the terminal block?

Is the connecting wiring of indoor

and outdoor firmly fixed?

Is drainage securely carried out?

Is the earth line securely

connected?

Is the indoor unit securely fixed?

Is power source voltage abided

by the code?

Is there any noise?

Put check mark in boxes

Is the lamp normally lighting?

Are cooling and heating (when

in heat pump) performed normally?

Is the operation of room temperature

regulator normal?

Flare tooling die

Correct

Incorrect

Lean Damage of flare Crack

Partial Too outside

A

8