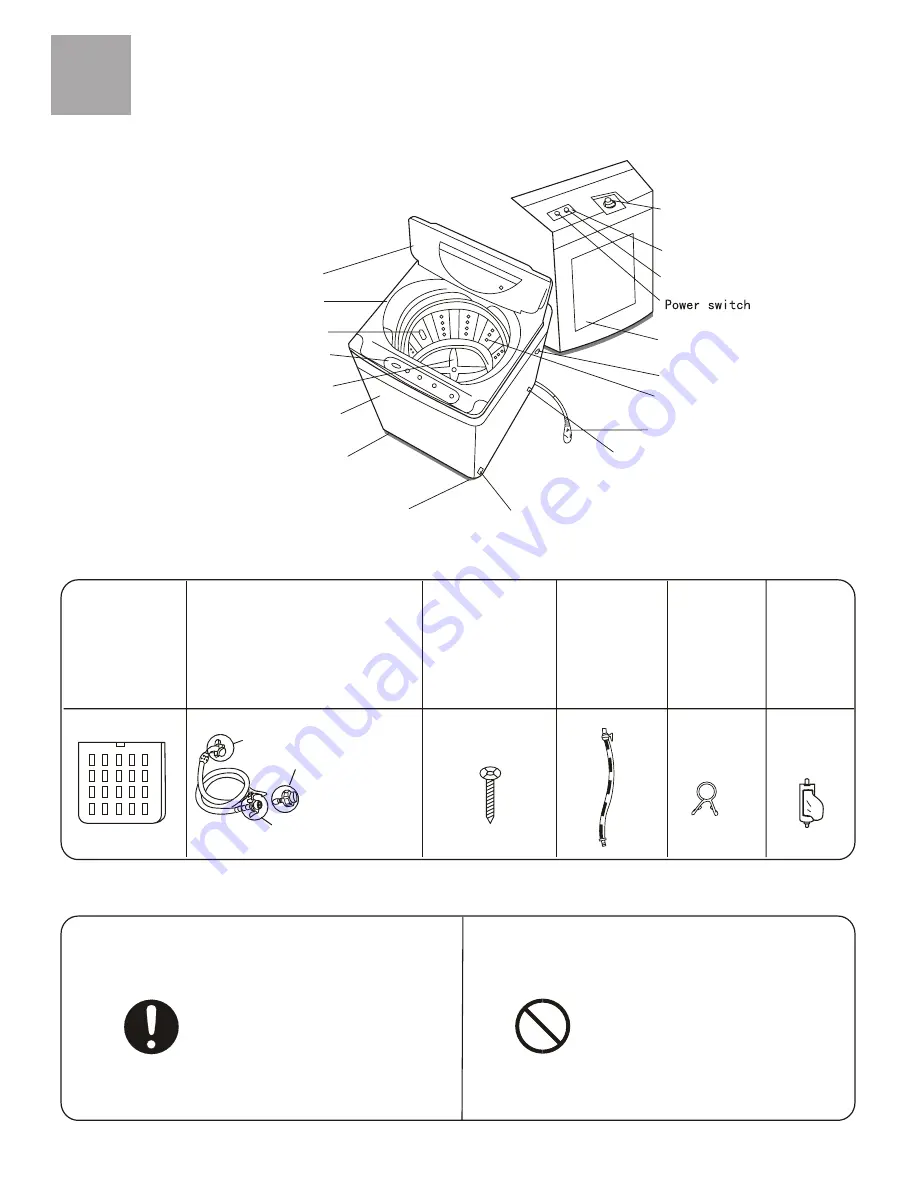

Names of the part s

Before using

Before using

Before using

Before using

Meaning and description of the symbols

Accessories

Contents marked with

that symbol are related

t o t h e s a f e t y o f t h e

product and the personal

safety of the users. Failure

t o c o m p l y w i t h t h e

instruction could cause

damage of the machine

o r i n j u r e t h e p e r s o n a l

s a f e t y o f t h e u s e r .

Warning

mark

Top lid

Control panel

Lint filter(Installed by user)

Control panel film

Pulsator

Cabinet

Base frame

Adjustable foot

seam

Adjustable foot

Inner drain hose

Power line

Inner tub

Cabinet handle

Back cover

Water level Switch

Control panel film

Water valve

Bottom plate

(1 piece)

The end connecting to

the washing machine

The end connecting to

the water inlet hose jointer

Jointer connecting

the water inlet hose

to the water faucet

Water inlet hose

(2 pieces)

Water inlet

hose jointer

(2 pieces)

Tapping screw

ST4x 16

(1 pieces)

Drain hose

(1 pieces)

Hose clamp

(1 pieces)

Lint filter

(1 piece)

Contents marked with

that symbol are actions

f o r b i d d e n t o p e r f o r m .

F a i l u r e t o c o m p l y w i t h

t h e i n s t r u c t i o n c o u l d

result in damage of the

m a c h i n e o r i n j u r e t h e

personal safety of the user.

Forbidding

mark