19

The appliance must be installed in compliance with applicable local regulations

concerning ventilation and the evacuation of exhaust gases.

Intensive and prolonged use may require extra ventilation, e.g. opening a window,

or more efficient ventilation increasing the mechanical suction power if this is fitted.

The room where the gas appliance is to be installed must have a natural flow of air

so that the gas can burn(in compliance with appliance local regulations).

The flow of air must come directly from one or more openings made in the outside

walls

with a free area of at least 100 cm

2

(or refer to applicable local regulations).

The openings should be near the floor and preferably on the side opposite the exhaust for

combustion products and must be made so that they cannot be blocked from either the

inside or the outside.

When these openings cannot be made,the necessary air can come from an adjacent room

which is ventilated as required,as long as it is not a bed room or a danger area(in

compliance with appliance local regulations).

In this case, the kitchen door must allow the passage of the air.

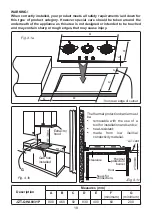

Extractor hoods connected directly to the outside must be provided, to allow the products

of combustion of the gas appliance to be dischanged(fig.4.2).

If this is not possible, an electric fan may be used, attached to the external wall or the

window; the fan should have a capacity to circulate air at an hourly rate of 3-5 times the

total volume of the kitchen(fig.4.3).

The fan can only be installed if the room has suitable vents to allow air to enter, as described

under the heading “Choosing suitable surroundings”.

VENTILATION REQUIREMENTS

CHOOSING SUITABLE SURROUNDINGS

DISCHARGING PRODUCTS OF COMBUSTION

H min 650

mm

Extractor hood

for products of

combustion

Air vent

Air vent

Electric fan to

extract products of

combustion

Fig. 4.3

Fig. 4.2